Sewage plant serial water treatment equipment with reverse osmosis function

A technology for water treatment equipment and sewage plants, applied in water/sewage treatment equipment, permeation/dialysis water/sewage treatment, water/sewage treatment, etc., can solve the problem of shortening the maintenance cycle of semi-permeable membranes and increasing the number of semi-permeable membranes in the cylinder Filter pressure, increase use cost and other issues, to achieve the effect of saving use cost, ingenious design, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

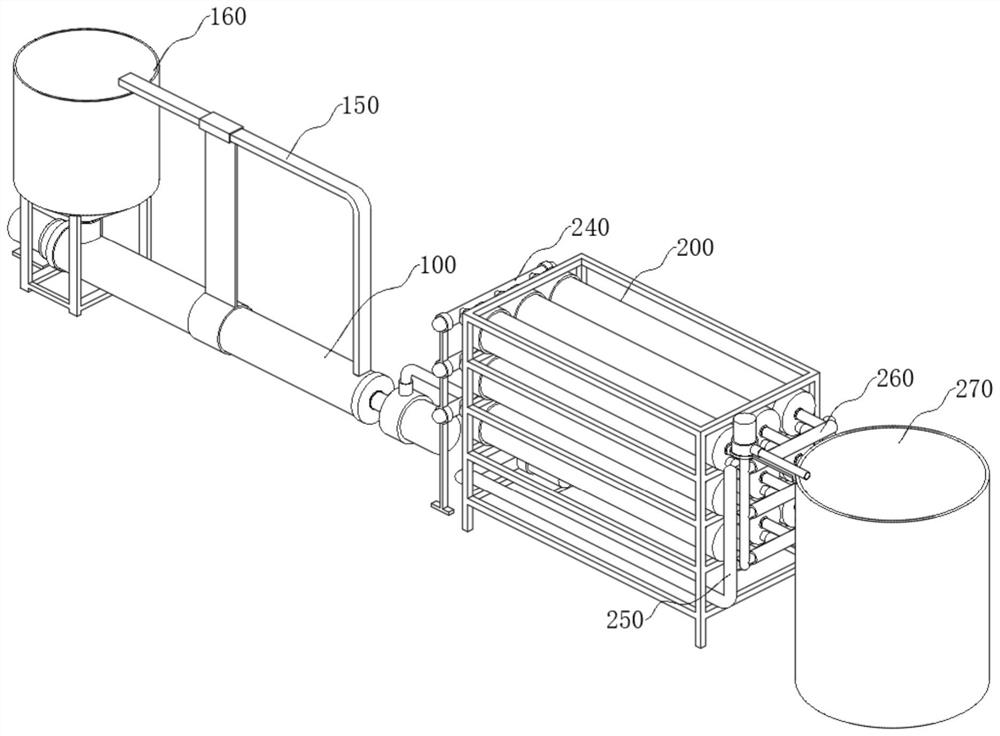

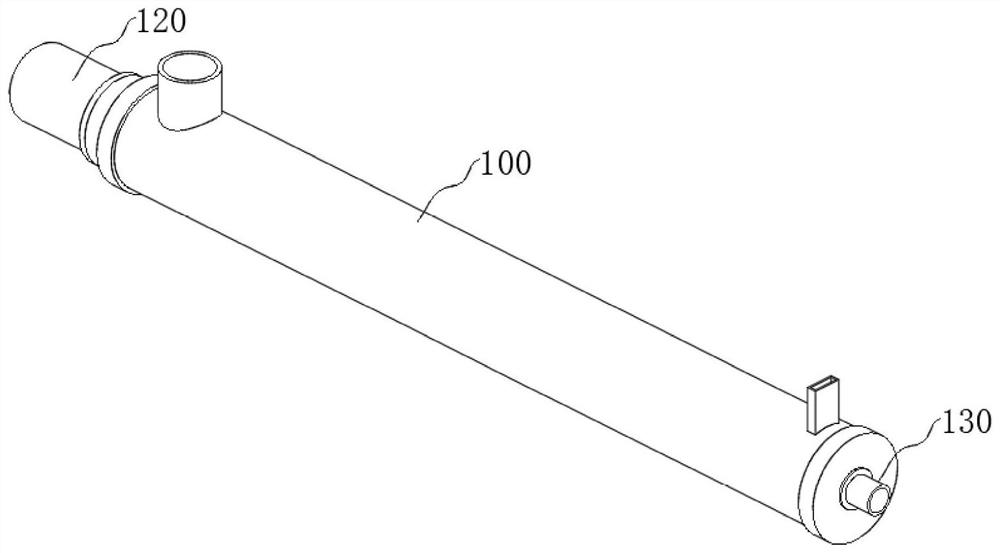

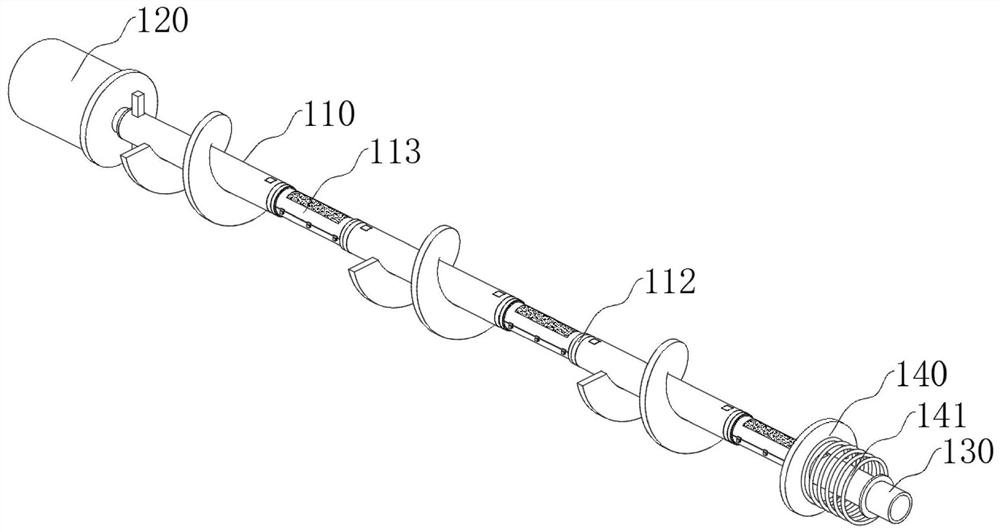

[0046] see Figure 1 to Figure 14 As shown, the present invention provides a sewage plant chain water treatment equipment with reverse osmosis function, comprising a primary filter pipe 100 and several secondary filter pipes 200 stacked in rows, the primary filter pipe 100 and several secondary filter pipes 200 is provided with a water inlet group 240, through the water inlet group 240, the net liquid (water molecules and various ions) filtered in the primary filter tube 100 is introduced into several secondary filter tubes 200 to continue purification, thereby improving the sewage purification efficiency , and also reduce the purification burden on the reverse osmosis membrane in the secondary filter tube 200, that is, the semi-permeable membrane, and prolong its service life. The tail end of several secondary filter pipes 200 is provided with a circulation group 250 for returning the filtered concentrated liquid to its front end, so that the filtered concentrated liquid can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com