Hoisting equipment used during subway construction

A kind of lifting equipment and subway technology, which is applied in the direction of trolley cranes, cranes, load hanging components, etc., can solve problems such as lifting and fixing devices that are difficult to move and cannot be bulky, and achieve simple lifting and transportation, work efficiency and safety High performance and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

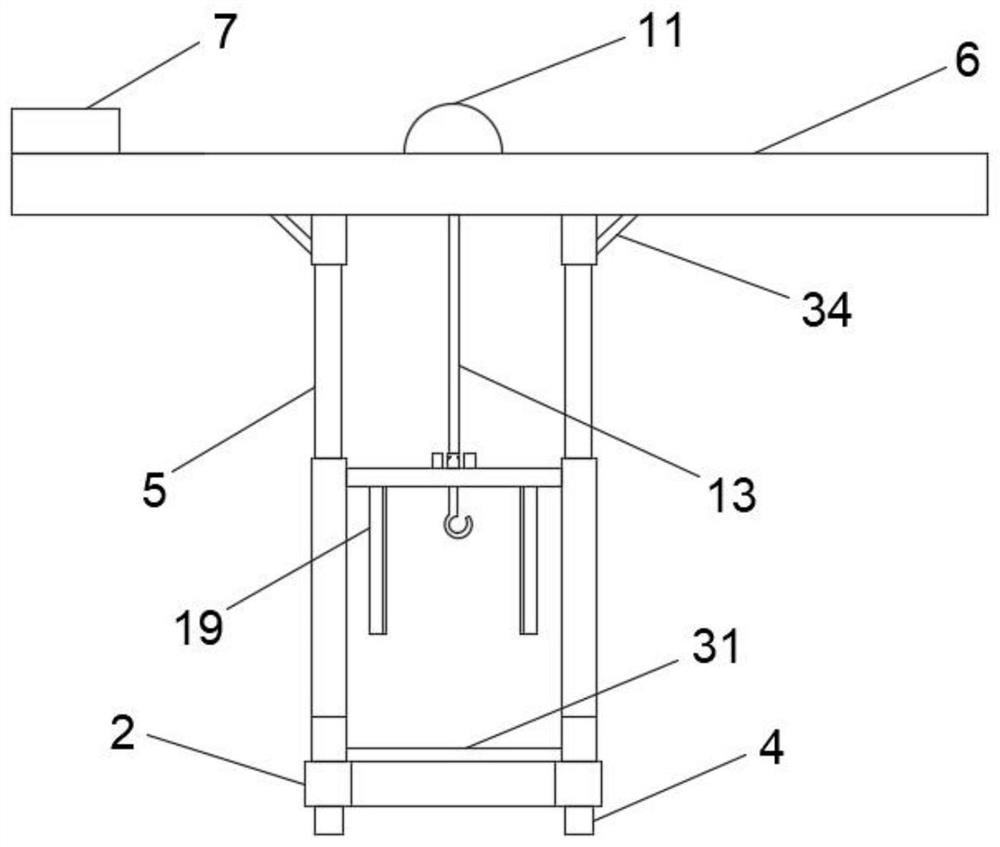

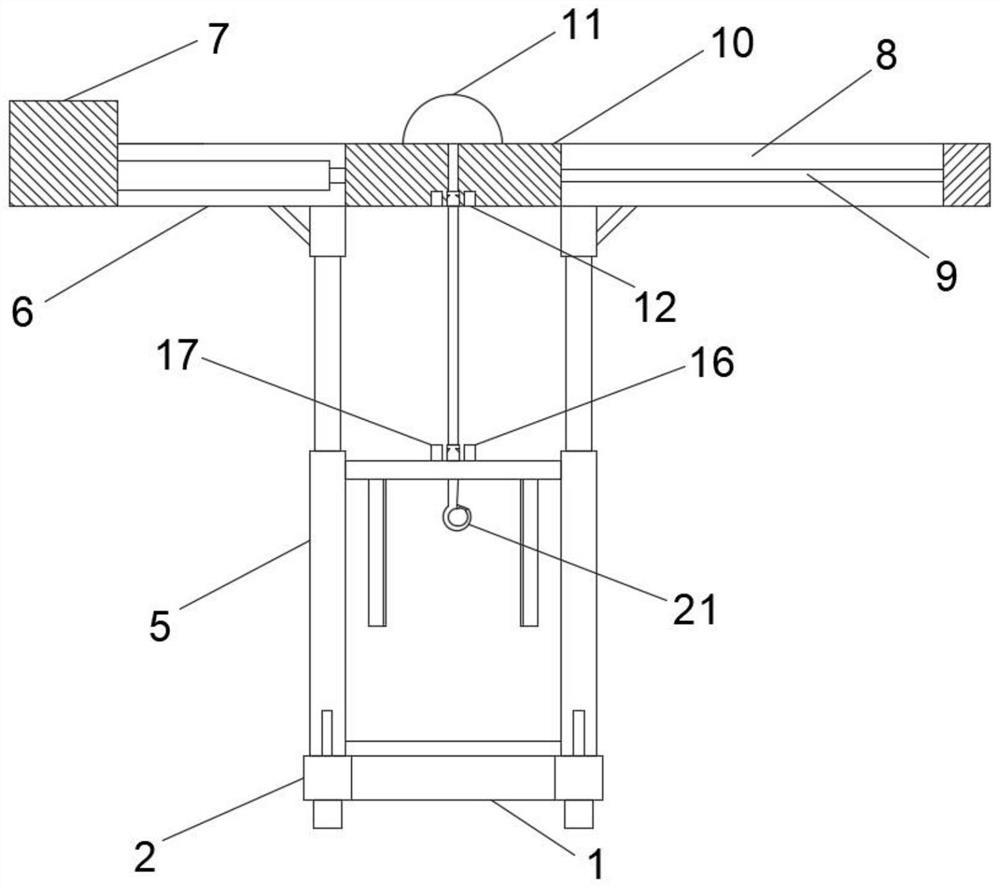

[0032] Such as figure 1 , figure 2 with image 3 As shown, a hoisting device used during subway construction includes a lifting mechanism. The lifting structure includes a base plate 1. Support beams 2 are fixedly connected to the left and right sides of the base plate 1. Guide rails 3 are laid below the support beam 2. The support beam 2 The pulley 4 fitted with the guide rail 3 is installed at the bottom, the pulley 4 has a brake device, and the hydraulic telescopic rod 5 is installed on the support beam 2, and two hydraulic telescopic rods 5 are installed on each support beam 2, and the hydraulic telescopic rod 5 sides The sides are equipped with support rods 34, and the tops of the four hydraulic telescopic rods 5 are jointly connected with a support plate 6. The layout direction of the support plate 6 is perpendicular to the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com