Die-cutting part machining system with shutdown device

A technology of shutdown device and processing system, applied in metal processing, transportation and packaging, coiling strips, etc., can solve problems such as affecting customer use and a large number of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

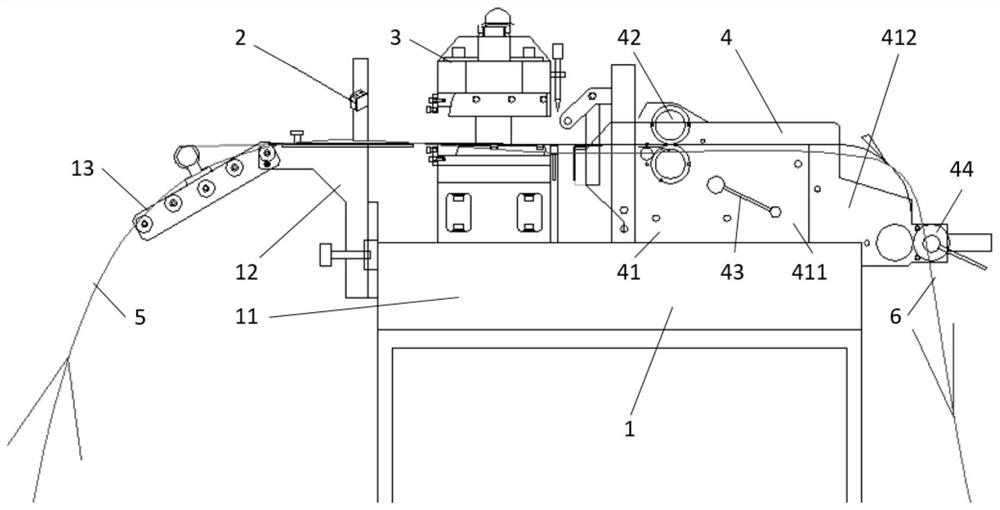

[0032] A die-cut processing system with a stop device, such as figure 1 , the system includes a working platform 1, a shutdown device 2, a die-cutting machine 3 that punches a material strip 5 to form a die-cut finished product 6, and a strip transmission device 4, a shutdown device 2, a die-cutting machine 3 and a strip transmission device 4 are fixed on the working platform 1 in turn.

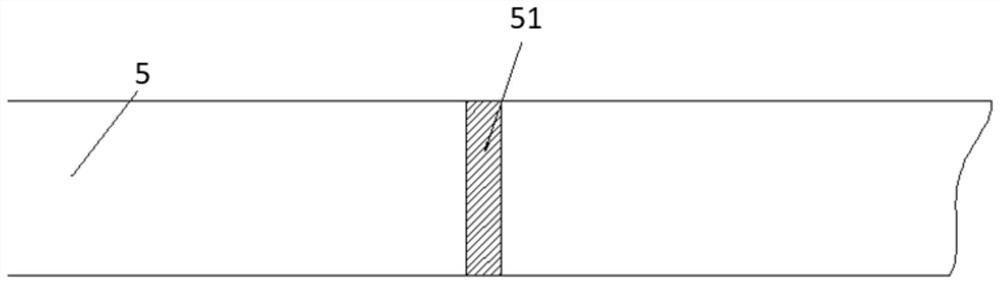

[0033] The material strip 5 and the die-cut finished product 6 are on the same main body of the material strip, but in order to distinguish them, the forward direction of the main body of the material strip is taken as the positive direction, and the part of the main body of the material strip before the die-cutting machine 3 is named as the material strip 5 , and the part after that is named die-cut finished product 6. Such as Figure 3-4 , the strip 5 includes at least one joint 51, the joint 51 is pasted with a single-sided adhesive, the color of the single-sided adhesive is different fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com