Small-diameter inner hole machining technology and equipment thereof

A small-diameter, inner-hole technology, applied in the field of machining, can solve the problems of affecting the processing speed, unable to meet the clamping of workpieces of different shapes, and poor clamping ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

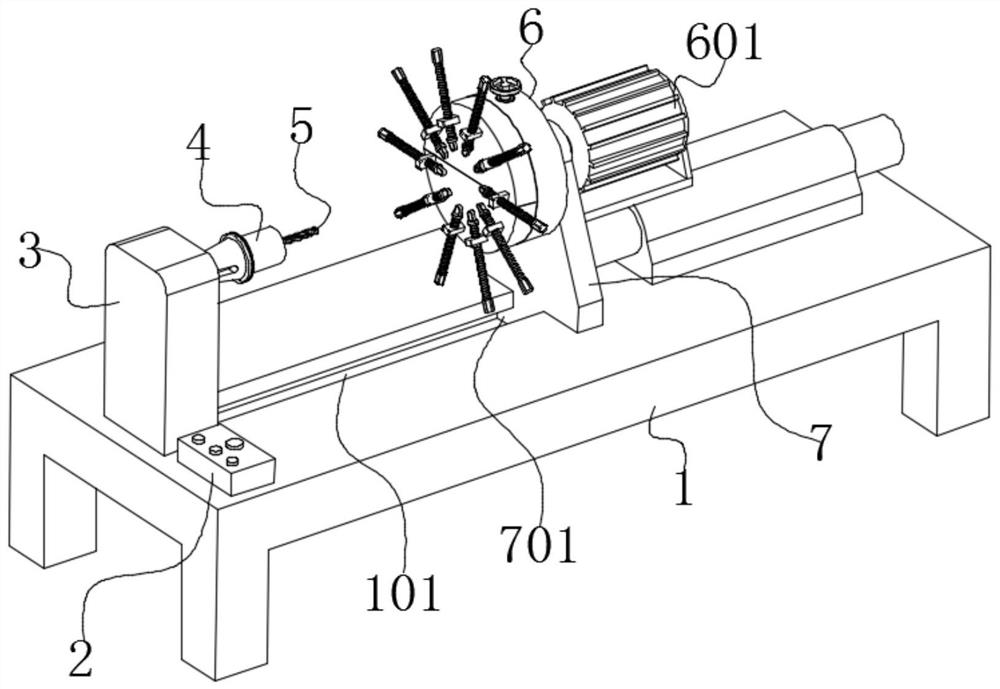

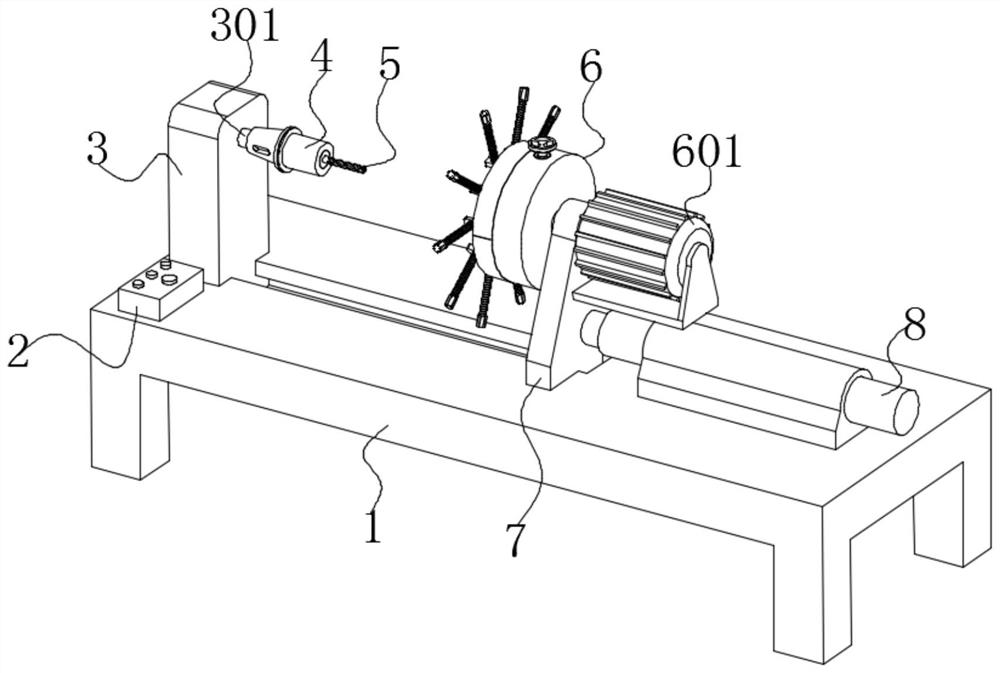

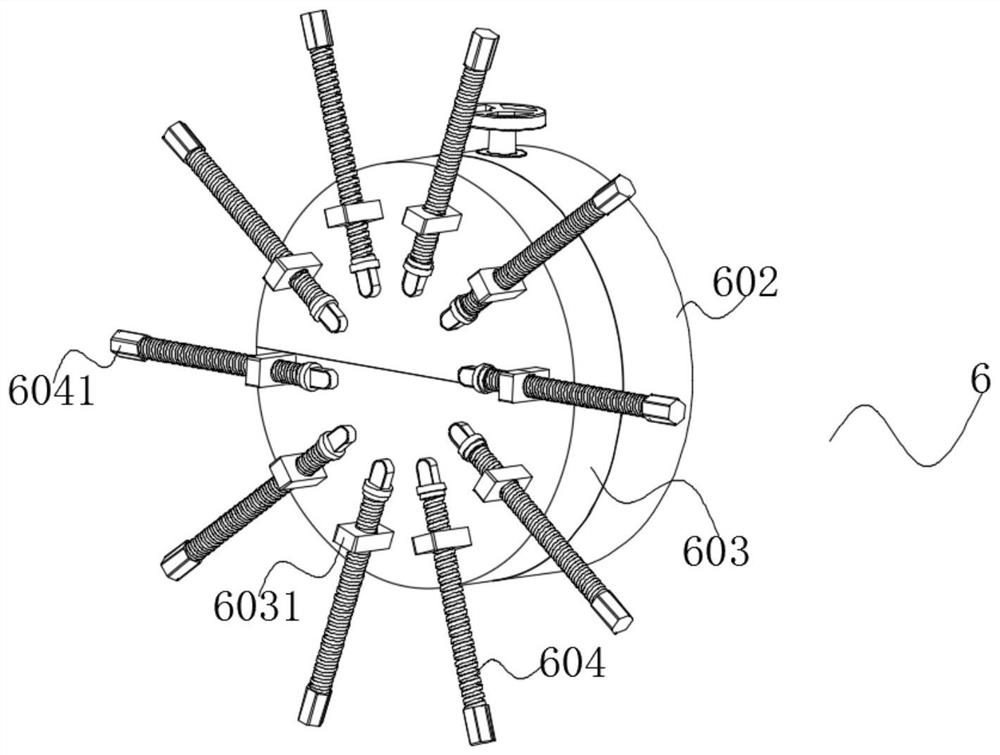

[0041] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

[0042] The present invention is a process for machining a small hole aperture, comprises the following process steps:

[0043] S1: Select the hole diameter corresponding to the inner cutter, and the cutter blade mounted on the sleeve by adjustable seat lathe, milling machine used to mill the cylindrical sidewall and the groove with a cutter knife;

[0044] S2: adjusting the main assembly of the two symmetrically arranged primary clamp is opened and the workpiece to be machined is placed in the hole between the two main clamper;

[0045] S3: a workpiece to be machined is aligned with the cutter position, and adjust the main assembly by the primary regulator clamp position, clamp the two main clamping implemented preliminarily fixed on a workpiece;

[0046] S4: by adjusting the position of suitable auxiliary adjustment assembly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com