Efficient mixing device for disinfectant production

A mixing device and disinfectant technology, applied in mixers, shaking/oscillating/vibrating mixers, packaging, etc., can solve problems such as high labor costs, need for manual packaging, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

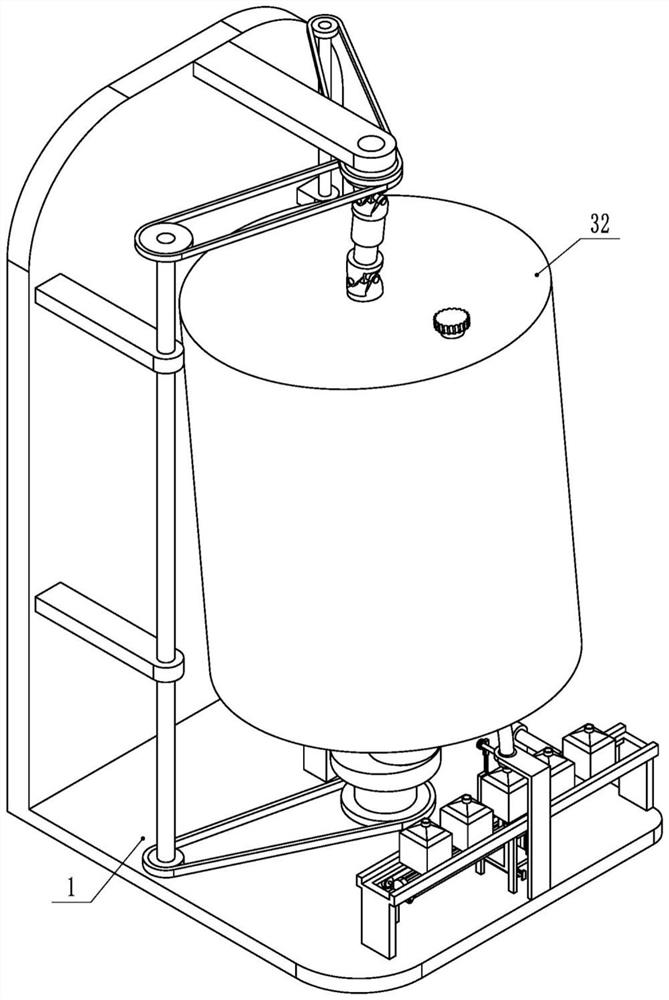

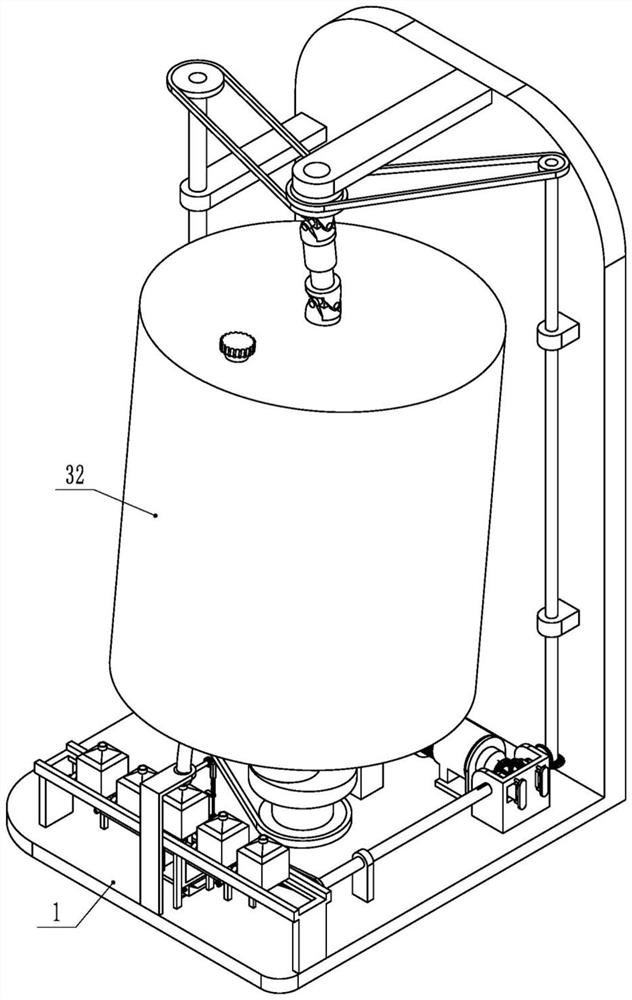

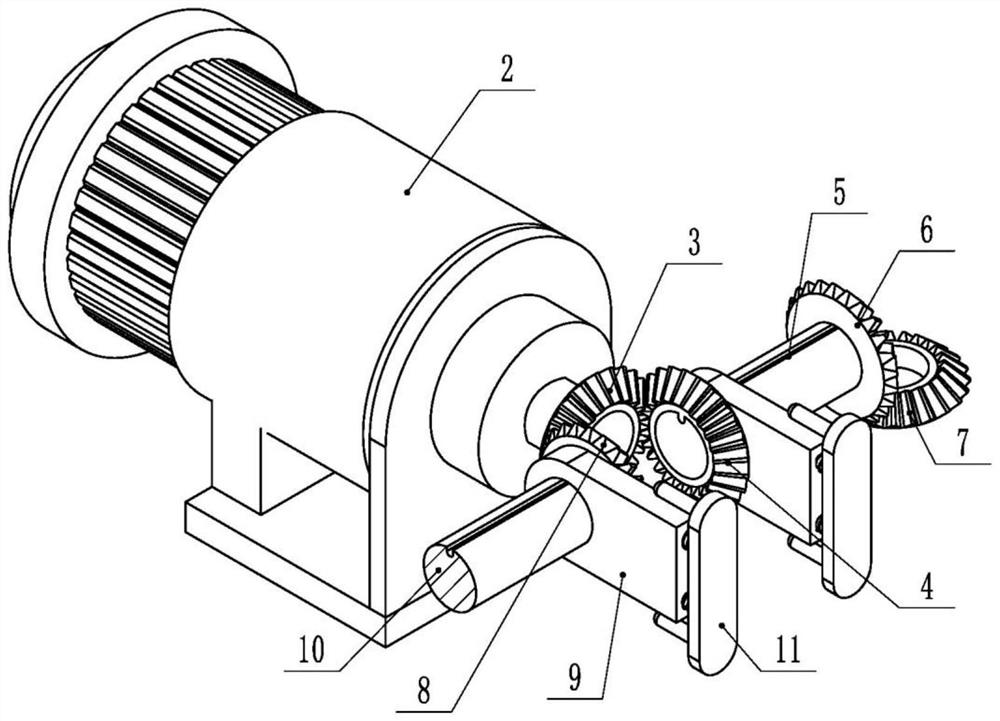

[0036] Such as Figure 1-18 As shown, the present invention provides a high-efficiency mixing device for disinfectant production, including a base 1, a mixing bucket 32 that can shake in a circle is installed on the rear side of the upper end of the base 1, and a rotatable long shaft is installed on the inner wall of the mixing bucket 32 21. Stirring frames 30 are installed on the left and right sides of the long rotating shaft 21. When the long rotating shaft 21 rotates, two stirring frames 30 can be formed to swing up and down while rotating and revolving; the upper surface of the base 1 is fixed on the front side. A concave slide 61 is connected, and a plurality of liquid bottles 86 are placed on the upper surface of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com