Crop anti-rolling irrigation machine based on agricultural large-scale irrigation and use method thereof

A crop, a large-scale technology, applied in the field of agriculture, can solve the problems of adjusting the scope of irrigation, waste of resources, adjustment, etc., to avoid rolling to crops, preventing crops from rolling, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

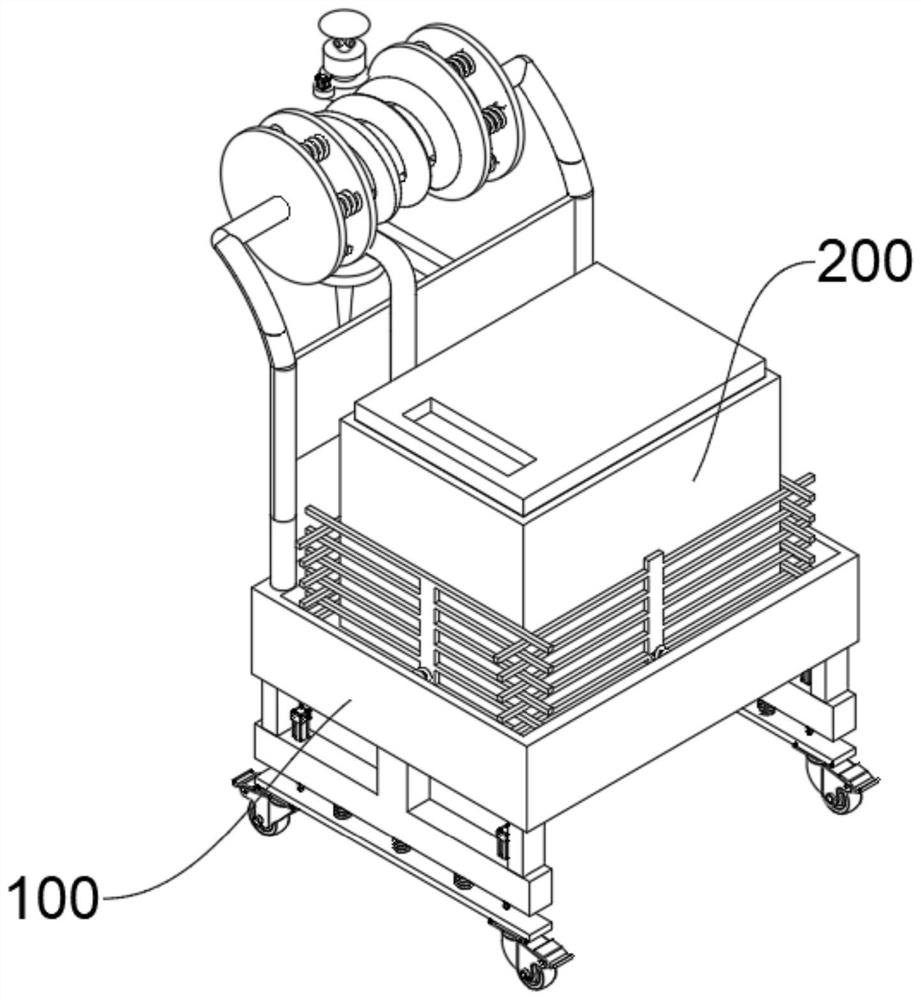

[0052] see Figure 1-Figure 6 As shown, this embodiment provides an anti-rolling irrigation machine for crops based on a wide range of agricultural irrigation, including at least:

[0053] Placement bucket 100, two symmetrical adjustment grooves 101 are provided at the bottom of the placement bucket 100, screw rods 102 are installed inside the adjustment grooves 101, the ends of the two screw rods 102 are fixedly connected with the first bevel gear 103, and the two second A second bevel gear 104 is meshed between the outer walls of a bevel gear 103, and the end of the second bevel gear 104 is connected with an output shaft of an adjustment motor 105, and the adjustment motor 105 is powered on to make it work. The output shaft drives the second bevel gear 104 to rotate, thereby meshing and driving the two first bevel gears 103 to rotate, so that the two screw rods 102 can rotate at the same time, and it is easier and more convenient inside the adjustment groove 101. There are t...

Embodiment 2

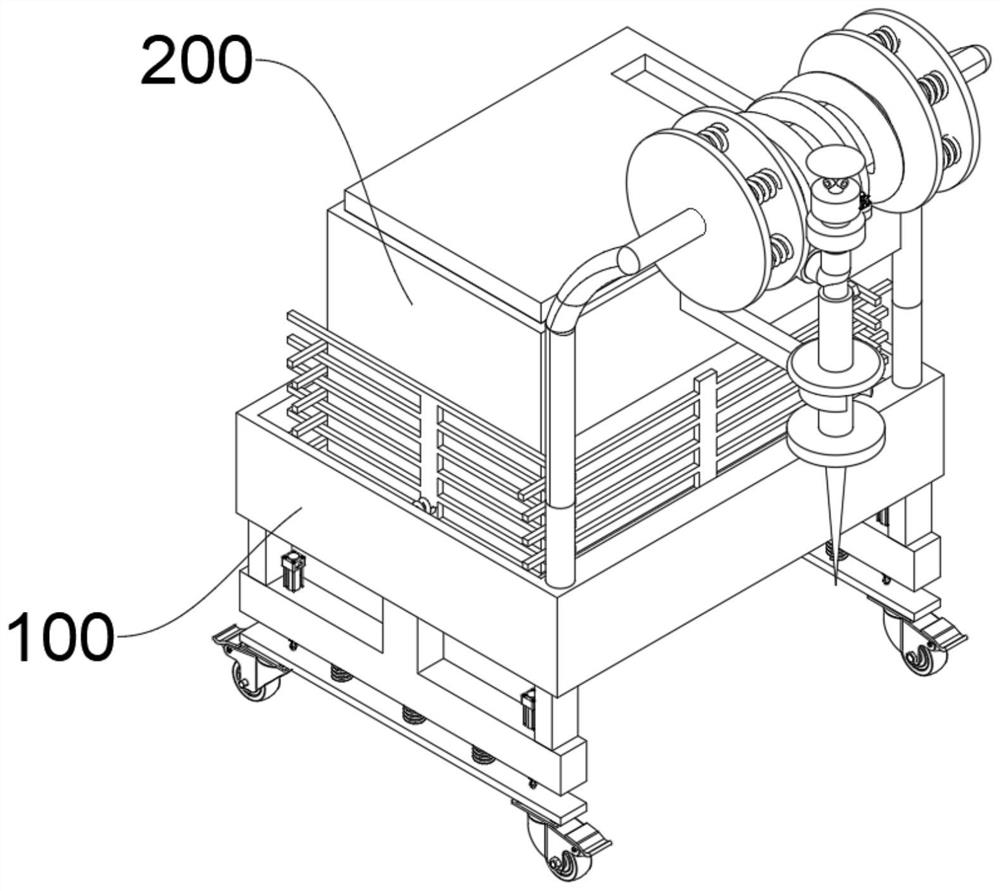

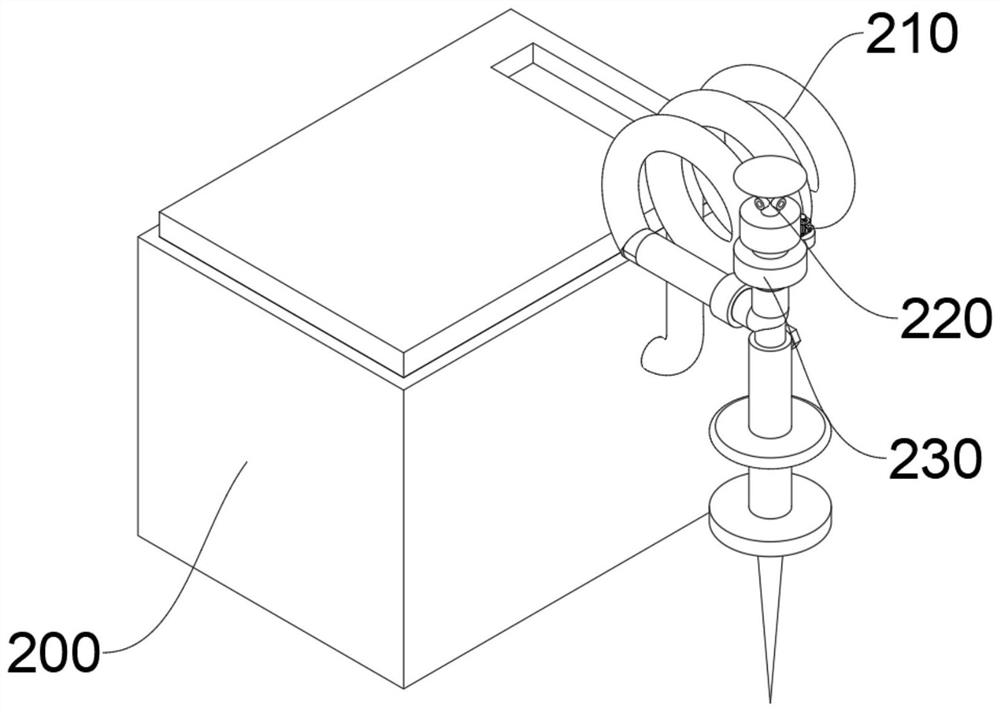

[0058] In order to wind the water pipe 210 around the outer wall of the finishing roller 121, avoid the water pipe 210 being dragged on the ground and be damaged, and avoid rolling the crops, the difference between this embodiment and the first embodiment is that, please refer to Figure 7 shown, where:

[0059] The edge of the placement bucket 100 is provided with a push rod 120, which can be held to push the placement bucket 100 to facilitate movement. The surface of the push rod 120 rotates with a finishing roller 121, and the two ends of the finishing roller 121 are fixedly connected to the limit plate 122, so that the water pipe can be moved. 210 is wound on the outer wall of the finishing roller 121, so that the water pipe 210 is spirally located between the two limiting plates 122, which can prevent the water pipe 210 from being dragged and damaged on the ground, and avoid rolling the crops, which is more practical.

[0060] It is worth noting that in order to limit and...

Embodiment 3

[0062] In order to clamp and limit the water tank 200 inside the placement bucket 100 and avoid falling during the movement, the difference between this embodiment and Embodiment 1 is that, please refer to Figure 8 shown, where:

[0063] Clamping plates 130 are provided on all four sides of the inner chamber of the placing bucket 100, and a fixed spring 131 is fixedly connected between the clamping plate 130 and the inner wall of the placing bucket 100, and the fixed spring 131 is compressed between the clamping plate 130 and the inner wall of the placing bucket 100. Put the water tank 200 inside the storage bucket 100, and the elastic force of the fixed spring 131 restores the clamping plate 130 to the water tank 200, and the clamping limit of the water tank 200 is inside the storage bucket 100, so as to avoid falling and pulling the clip during the movement. The holding plate 130 keeps the holding plate 130 away from the water tank 200, which facilitates subsequent removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com