Micro-crushing device suitable for biomass straw

A biomass straw and micro-grinding technology, which is applied in the field of micro-grinding devices and biomass straw micro-grinding devices, can solve problems such as the inability to meet the high-efficiency crushing operations of biomass straws, and achieve increased work utilization, improved crushing quality, and convenience The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

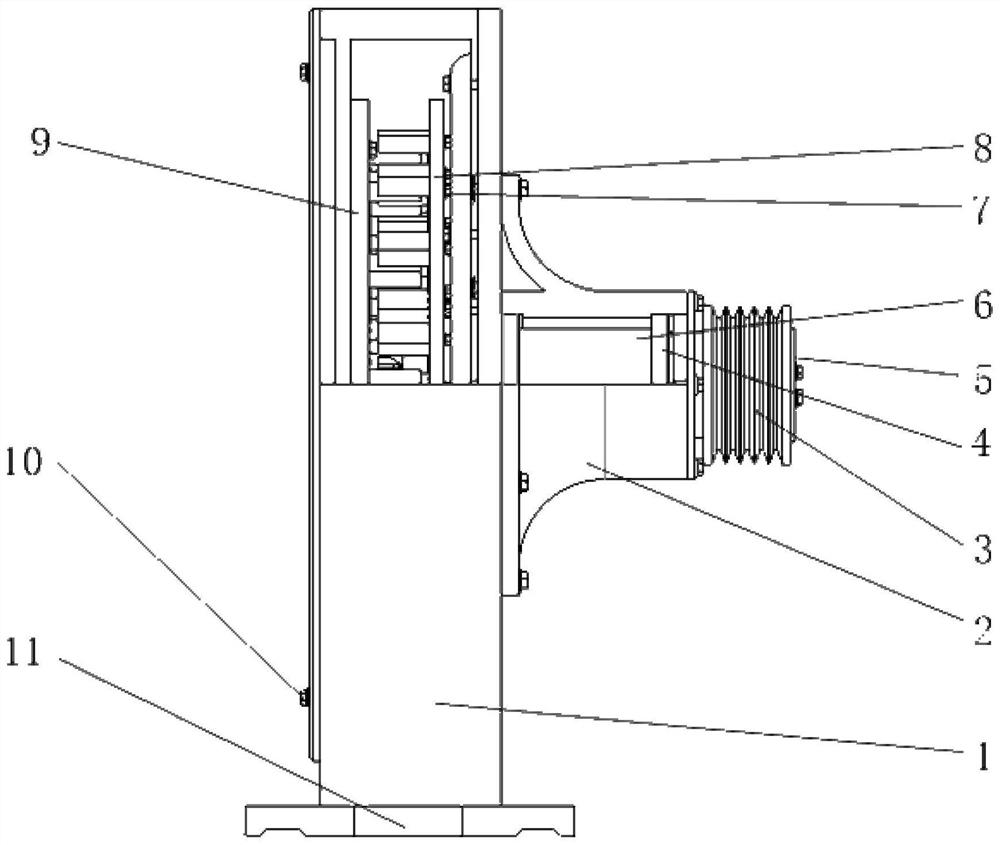

[0040] Example: see Figure 1-Figure 6 , a crushing device suitable for biomass straw in this embodiment, including a casing 1, a bearing seat 2, a pulley 3, a bearing 4, a shaft end retaining ring 5, a rotating shaft 6, a nut 7, a rotor mechanism 8, a stator Mechanism 9, bolt 10, discharge port 11;

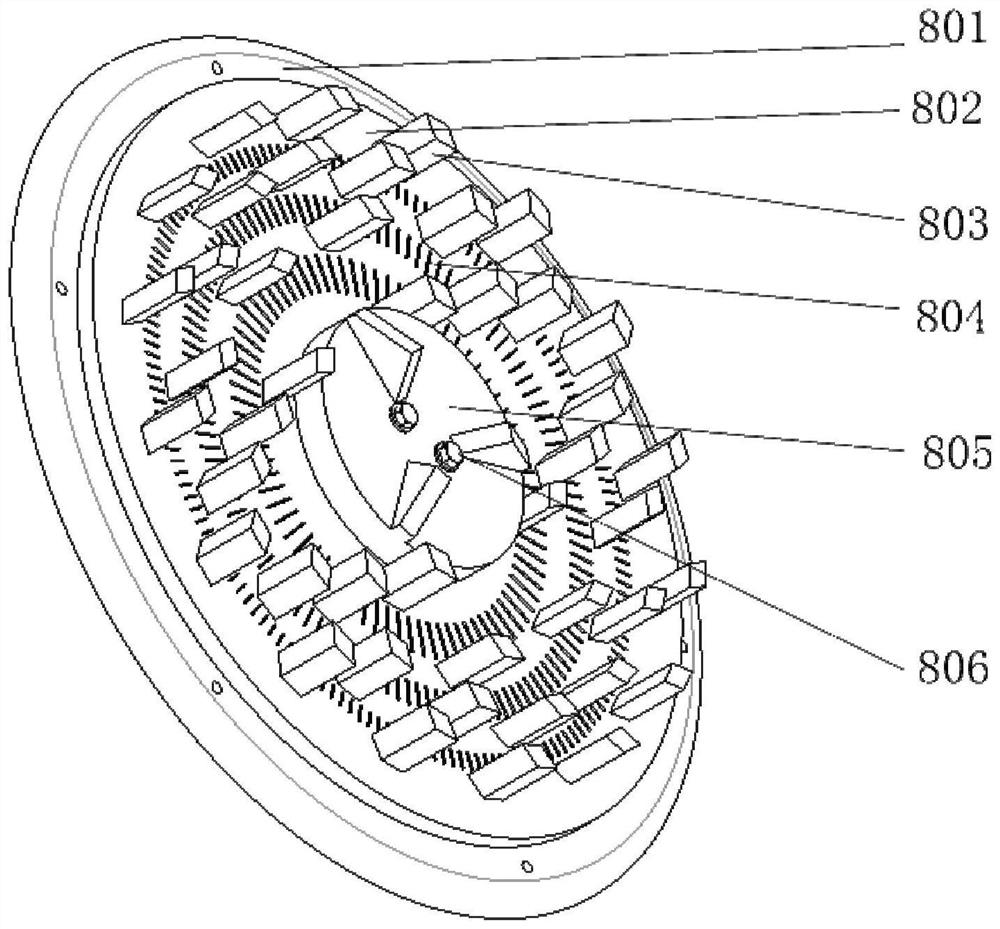

[0041] The rotor mechanism includes a retaining ring 801, a movable cutter disc 802, a movable cutter 803, convex teeth 804, a cutting edge disc 805 and a bolt 806; the boss on the movable cutter 803 matches the groove on the movable cutter disc 802, The cutter is fixed on the movable cutterhead 802 by the nut 7; the cutting edge disk is fixed to the rotating shaft 5 and the movable cutterhead 802 by the bolt 806;

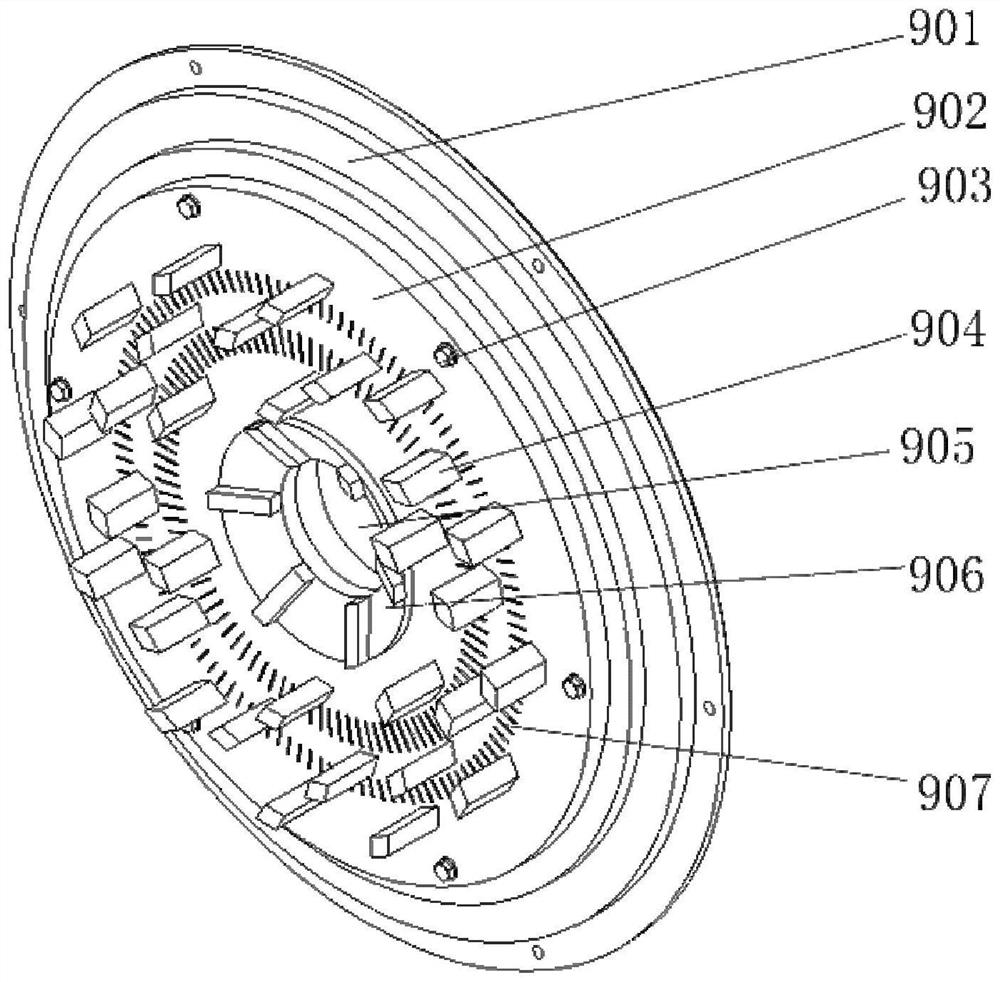

[0042] The stator mechanism includes a front door 901, a fixed knife disc 902, a bolt 903, a fixed knife 904, a material inlet 905, a cutting disc 906 and convex teeth 907; the front door 901 is fixed on the casing 1 by bolts, and the front door 901 has Groove, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com