Open-type TBM expanding excavation head falling prevention method

An open and anti-planting technology, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., can solve the problems of deviation from the original design course, tunnel construction quality accidents, and large deviation of the excavation direction, so as to improve the construction quality and construction period. Short, convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

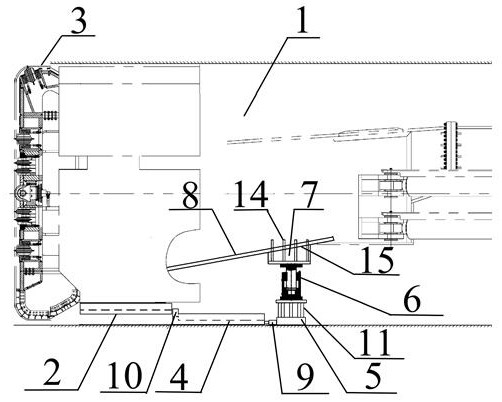

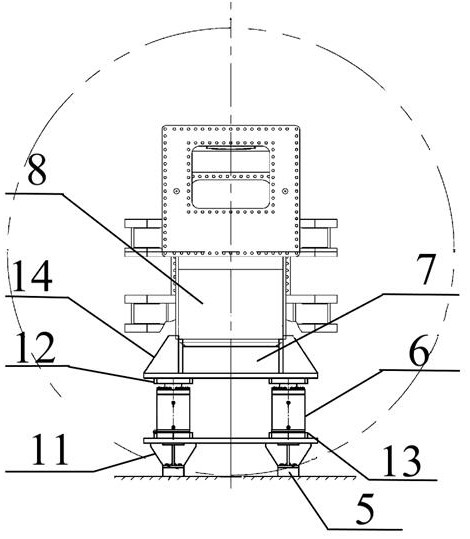

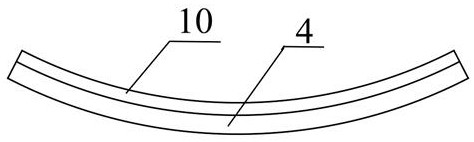

[0029] Embodiment 1: as figure 1 , 2 As shown in , 3, an open-type TBM excavation and anti-heading method, the method includes the following steps: 1) Excavation expansion; 2) Cleaning up the slag at the bottom of the arch in the area behind the bottom shield 2; 3) Retreating the cutter head 3 ;4) Align the curved steel plate 4 and place it behind the bottom shield 2; 5) Place the jacking device under the main beam 8; 6) Place the jack 9 between the curved steel plate 4 and the jacking device; 7) Start The jacking device raises the cutter head 3 and the bottom shield 2; 8) Use the jack 9 to push the curved steel plate 4 under the bottom shield 2; 9) Remove the jack 9 and remove the jacking device.

[0030] In the step 1), the excavation is extended to 6m-8m; in the step 3), the cutter head 3 is retreated to 0.2m-0.5m.

[0031] Further description, in the present invention, the jacking device includes a cylinder bottom support 5 placed at the bottom of the tunnel arch, a jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com