Mechanically-connected prefabricated special-shaped pile

A mechanical connection, prefabricated technology, applied in sheet pile walls, non-rotational vibration suppression, construction, etc., can solve problems such as no quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

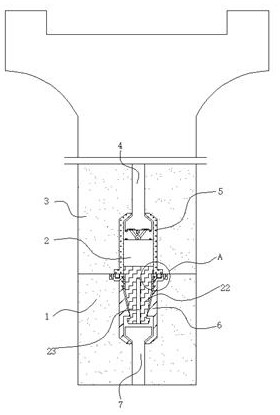

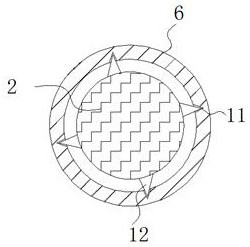

[0032] Example 1: See Figure 1-8 , a mechanically connected prefabricated special-shaped pile, including a lower prefabricated pile 1, an elastic barb tooth 12 and a locking member 22, and also includes a reinforcement mechanism 8 for a firm connection, a buffer mechanism 13 for avoiding pile breakage, and an installation for quick connection structure;

[0033] An upper prefabricated pile 3 is installed above the lower prefabricated pile 1, and an upper prefabricated installation part 5 is installed on the inner side of the upper prefabricated pile 3, and an upper prestressed steel bar 4 is installed above the upper prefabricated installation part 5, and the lower prefabricated pile 1 A lower pre-embedded installation part 6 is installed on the inner side, a lower prestressed steel bar 7 is installed under the lower embedded installation part 6, and a reinforcement mechanism 8 is installed on both sides of the top of the lower embedded installation part 6;

[0034] The inne...

Embodiment 2

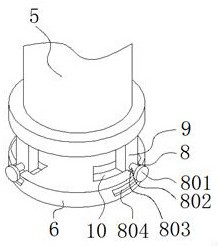

[0041] Embodiment 2: The reinforcement mechanism 8 includes a snap ring 801, a connecting column 802, and a groove 803. Grooves 803 are provided on the outer walls on both sides above the lower embedded mounting part 6, and a limiting hole 804 is provided on the side below the groove 803. , the inner side of the limit hole 804 is installed with a connecting column 802, and one end of the connecting column 802 is connected with a snap ring 801;

[0042] The other end of the connecting column 802 is connected with a mounting block 9, and the top of the embedded mounting part 6 under the mounting block 9 is provided with a mounting groove 10;

[0043] Specifically, such as figure 1 , figure 2 , Figure 4 with Figure 5 As shown, when using this structure, the installation block 9 is installed in the installation groove 10, and then the connecting column 802 is stuck in the groove 803, and then the upper prefabricated pile 3 is rotated to make the upper embedded installation par...

Embodiment 3

[0044] Embodiment 3: The buffer mechanism 13 includes a support rod 1301, a hinge 1302 and an elastic rubber block 1303. The hinge 1302 is installed on the top of the fixture 2, and both sides of the hinge 1302 are articulated with a support rod 1301. Above the hinge 1302 An elastic rubber block 1303 is installed at the bottom of the upper prestressed steel bar 4;

[0045] Limiting grooves 17 are arranged on both sides of the bottom end of the upper prestressed steel bar 4, and the top of the support rod 1301 is connected with the limiting groove 17 through the limiting block 15;

[0046] A first magnet 14 is installed on both sides of the top of the fixture 2, and a second magnet 16 is installed on the bottom of the prestressed steel bar 4 above the first magnet 14;

[0047] Specifically, such as figure 1 with Image 6 As shown, when this structure is used, the upper prefabricated pile 3 and the lower prefabricated pile 1 are subjected to impact vibration during pile sinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com