Resin molded article for sealing optical semiconductor, optical semiconductor sealing material, and optical semiconductor device

An optical semiconductor device and optical semiconductor technology, which are applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problem of cracking of small pieces of resin, and achieve the effect of not easy to crack and excellent optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

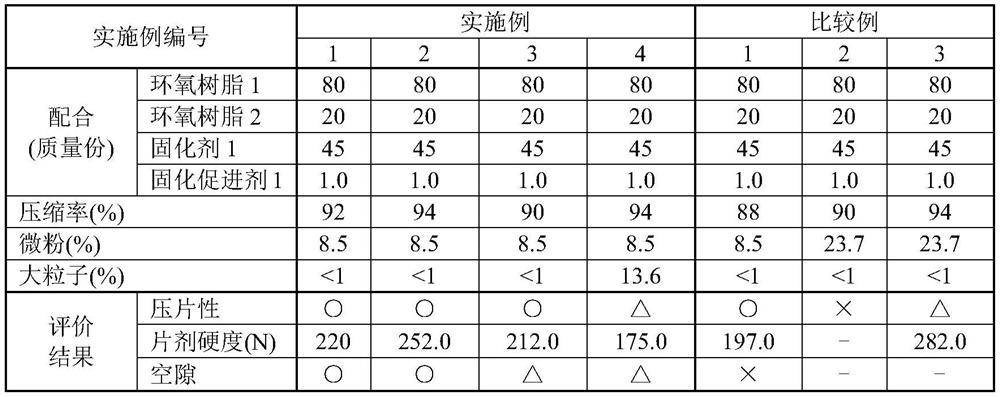

Embodiment 1~4 and comparative example 1~3

[0069] Heat, melt and mix each raw material in an extruder set at 130°C in the compounding amount shown in Table 1, and then mold the resin discharged from the discharge port of the extruder into a thickness of 2mm to 10mm. Under heat treatment for 60 minutes, an epoxy resin composition was obtained. The resulting epoxy resin composition was granulated by a dry compression granulator, then pulverized with a turbo mill, and then 120 mesh sieves and 10 mesh sieves were used to adjust the particle diameter as shown in Table 1. The micropowder and The proportion of large particles with a particle size of 2000 μm or more. Then, the obtained powder was pelletized into a diameter of 13 mm and a weight of 2.4 g using a rotary tablet press, thereby producing resin pellets for optical semiconductor encapsulating with compression ratios shown in Table 1.

[0070] Using the obtained pellets, tabletability, tablet hardness and voids were evaluated by the following methods. The results ar...

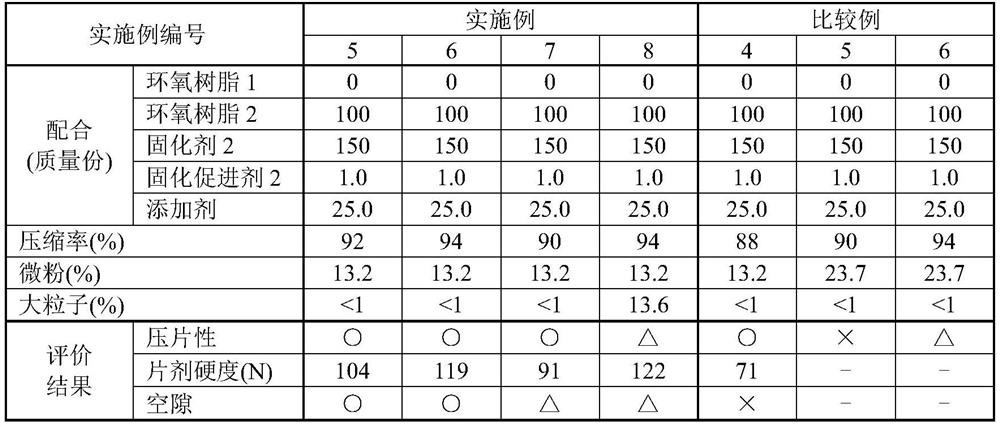

Embodiment 5~8 and comparative example 4~6

[0085] Except having used each raw material in the compounding quantity shown in Table 2, it carried out similarly to Examples 1-4 and Comparative Examples 1-3, and produced the resin pellet for optical semiconductor encapsulation. Using the obtained pellets, tabletability, tablet hardness and voids were evaluated by the methods described above. The results are shown in Table 2.

[0086] Table 1

[0087]

[0088] Table 2

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com