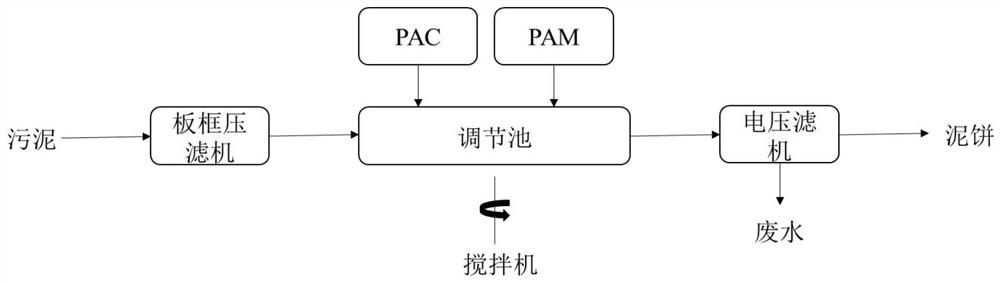

Method for intensifying sludge voltage filtration dehydration by using composite additive

A composite additive and sludge technology, applied in chemical instruments and methods, electrochemical sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as moisture content reduction, secondary pollution, and bulky sludge. Achieve the effect of improving dehydration performance, ensuring continuity and enhancing free water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

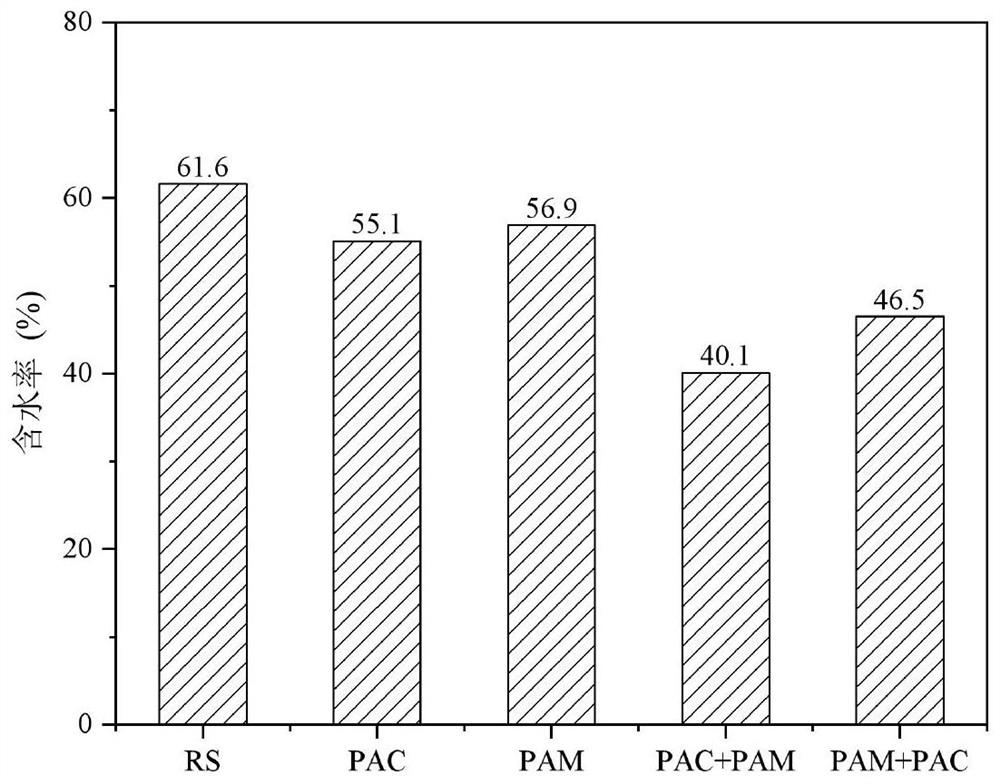

Embodiment 1

[0040] Take the sludge with a moisture content of 79.2% after dehydration by a plate and frame filter press with a working pressure of 2MPa in the sludge treatment plant, first add PAC with a sludge quality of 1.6‰, stir evenly, and then add PAM with a sludge quality of 0.2‰ , sent to the voltage filter for drying and dehydration, the operating voltage is 16V, the operating current is 3.2A, the mechanical pressure is 0Mpa for 0-4min, 1Mpa for 4-6min, and 2Mpa for 6-20min. After dehydration, the moisture content of the sludge was reduced to 39.8%.

Embodiment 2

[0042]Take the sludge with a water content of 83% after dehydration by a plate and frame filter press with a working pressure of 2.5MPa in the sludge treatment plant, first add aluminum sulfate with a sludge mass of 1‰, stir evenly, and then add a sludge mass of 0.6‰ The sodium polyacrylate is sent to the voltage filter for drying and dehydration, the operating voltage is 16V, the operating current is 3.2A, the mechanical pressure is 0Mpa for 0-4min, 1Mpa for 4-6min, and 2Mpa for 6-20min. After dehydration, the moisture content of the sludge reaches 43.7%.

Embodiment 3

[0044] Take the sludge with a moisture content of 85% after dehydration by a plate and frame filter press with a working pressure of 1MPa in the sludge treatment plant, first add iron sulfate with a sludge mass of 2‰, stir evenly, and then add 0.12‰ of the sludge mass PAM is sent to the voltage filter for drying and dehydration, the operating voltage is 10V, the operating current is 2A, the mechanical pressure is 0Mpa for 0-4min, 1Mpa for 4-6min, and 2Mpa for 6-20min. After dehydration, the moisture content of the sludge reaches 42.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com