Anti-wrinkle non-woven fabric winding device and using method thereof

A winding device and non-woven fabric technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of winding wrinkles, gaps, etc., to ensure cleanliness and improve toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

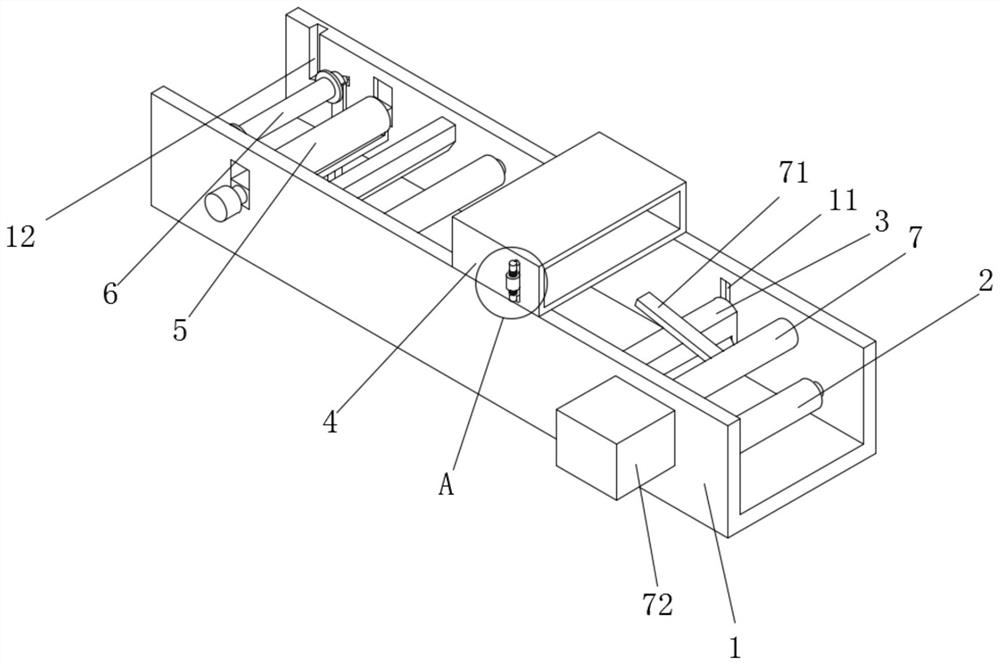

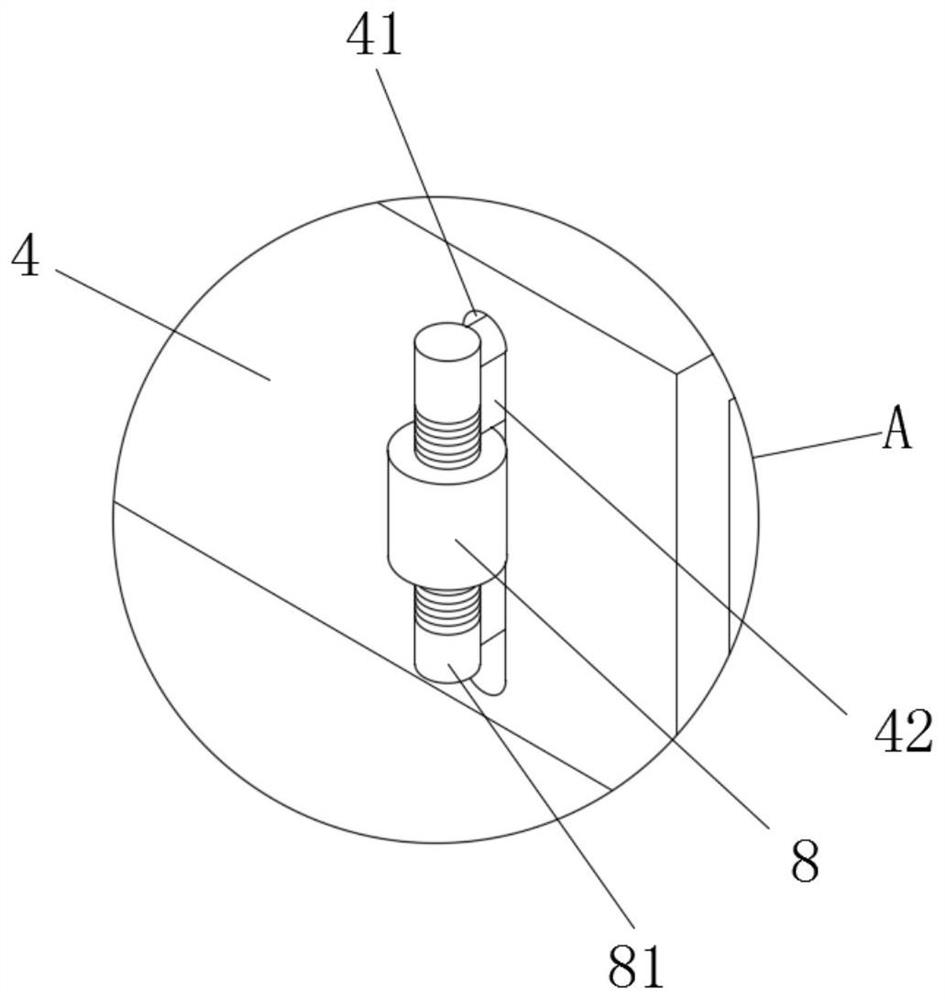

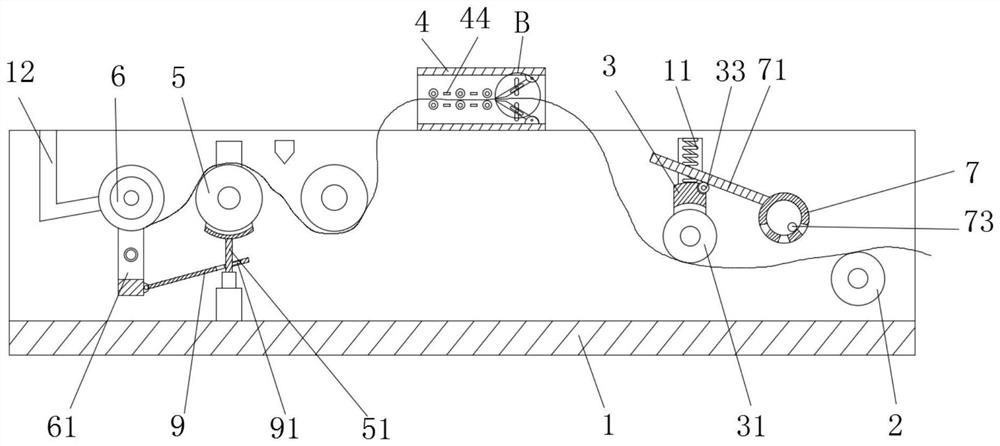

[0032] see Figure 1-5 , This embodiment provides a wrinkled non-woven fabric winding device, including a workbench 1, and a conveying roller 2 is installed in rotation inside the workbench 1, and conducts and conveys the non-woven fabric.

[0033] A support frame 3 is slidably installed inside the workbench 1 to support the pressing roller 31, and the support frame 3 slides along the vertical direction to drive the pressing roller 31 to slide along the vertical direction.

[0034] In order to ensure that the pressing roller 31 can always provide a downward pressing force to the non-woven fabric, so that the non-woven fabric is always in a tensioned state, the inner side wall of the workbench 1 is provided with a chute 11 for installing the support frame 3, and the support frame 3 The outer wall is fixedly equipped with a slider 32 that matches the chute 11. The chute 11 and the slider 32 are used together to limit the position of the support frame 3. The slider 32 and the chu...

Embodiment 2

[0047] see figure 1 , image 3 with Image 6 , a further improvement made on the basis of Example 1: in order to improve the toughness of the non-woven fabric when the tension of the non-woven fabric is too large, so as to avoid the non-woven fabric from breaking, between the conveying roller 2 and the pressing roller 31 The air jet tube 7 is installed in rotation, and the non-woven fabric is sprayed wet by the rotation of the air jet tube 7, thereby improving the toughness of the non-woven fabric and preventing the non-woven fabric from breaking.

[0048] An atomization box 72 is fixedly installed on the outer wall of the workbench 1 to provide a source of moisture to the spray tube 7, wherein the atomization box 72 can be a gas compression atomizer in the prior art.

[0049] The side wall of the workbench 1 and the inner wall of the jet tube 7 are all provided with an air inlet 73 for the atomized gas to enter the inside of the jet tube 7 , and the air inlet 73 provided on...

Embodiment 3

[0056] see figure 1 , image 3 with Figure 7 , a further improvement made on the basis of Example 2: In order to be able to cut the non-woven fabric at the same time, the winding roller 6 can be disengaged, so as to facilitate the removal of the winding roller, a fixed roller is installed inside the workbench 1 , the fixed roller is located between the driving roller 5 and the processing box 4, a cutting knife is fixedly installed inside the workbench 1, and the cutting knife is located between the driving roller 5 and the fixed roller, and the non-woven fabric is pressed by the fixed roller to ensure that the driving roller 5. When the non-woven fabric is driven to contact with the cutting knife, the non-woven fabric can be cut.

[0057] The inside of the workbench 1 is slidably installed with a casing, which protects the driving roller 5 and drives the casing to rise, so that the driving roller 5 can still rotate.

[0058] The driving roller 5 is rotatably installed insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com