Crushing device for textile raw material production and processing

A pulverizing device and raw material technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of poor pulverization and cutting effect, and achieve the effects of small vibration damage, stable motion transmission, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

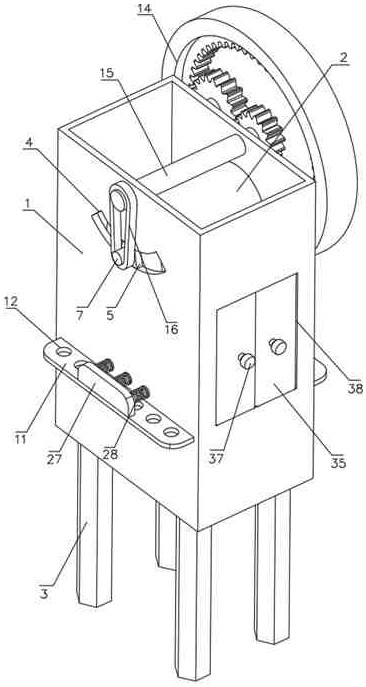

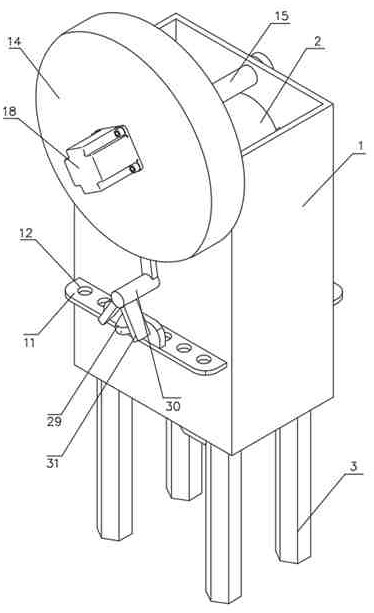

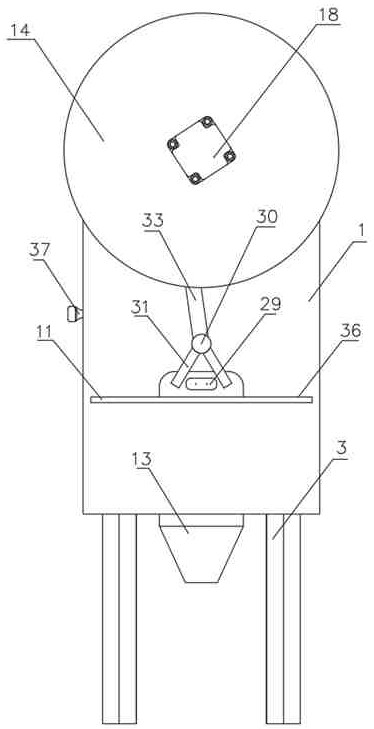

[0028] refer to Figure 1-5 , a crushing device for the production and processing of textile raw materials, comprising a processing box 1 and a crushing box 2, a plurality of legs 3 are fixed on the bottom of the processing box 1, and two track grooves 4 are provided through the side wall of the processing box 1, two The inner wall of the track groove 4 is slidably connected with the bearing slider 5 and the driving slider 6 respectively, and the side wall of the crushing box 2 is fixed with a crushing shaft 7, and the two ends of the crushing shaft 7 are respectively connected with the bearing slider 5 and the driving slider 6. Rotationally connected, the inner wall of the crushing box 2 is fixed with a plurality of cutting blades 10, the side wall of the crushing box 2 is provided with a discharge chute 8, and the inner wall of the discharge chute 8 is rotatably connected with two closing plates 9, the inside of the processing box 1 A screening and collecting mechanism is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com