Production device of activated carbon for sucrose stock solution adsorption

A production device and activated carbon technology, which are applied in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

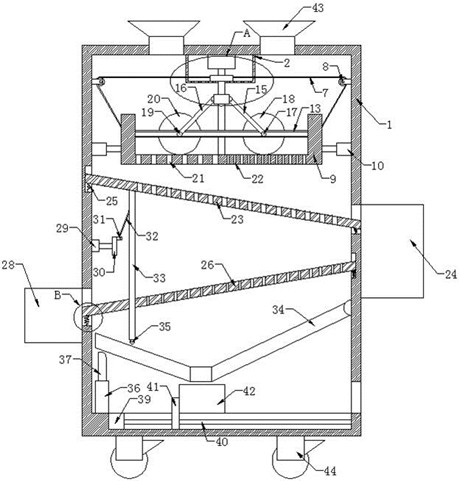

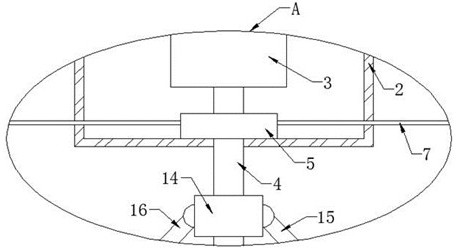

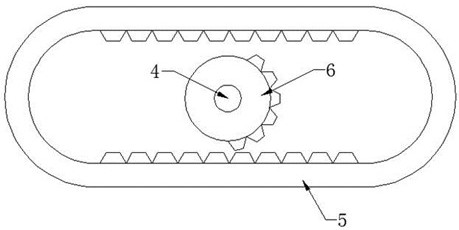

[0027] Embodiment one, by Figure 1-7Provided is a production device for activated carbon for sucrose stock solution adsorption, including a housing 1, an installation box 2 is fixed inside the housing 1, a first motor 3 is installed on the top of the inside of the housing 1, and the first motor 3 is located in the installation box 2, the output shaft of the first motor 3 is fixed with the first screw 4, the missing gear 6 is fixedly sleeved on the first screw 4, and the inside of the installation box 2 is slidably installed with the ring gear 5, the missing gear 6 and the tooth The gear teeth on the ring 5 mesh with each other, the inner wall of the housing 1 is equipped with a grinding seat 9 through a buffer mechanism, a rope 7 is connected between the ring gear 5 and the grinding seat 9, a fixed pulley 8 is fixed on the inner wall of the housing 1, and the rope 7. Rolling and socketed on the fixed pulley 8, one end of the first screw rod 4 is rotated and socketed inside th...

Embodiment 2

[0028] Embodiment two, by Figure 8 Given, the translation mechanism includes a third motor 39, a second screw mandrel 40, the third motor 39 is installed in the third chute, the output shaft of the third motor 39 is fixed with a second screw mandrel 40, and the second screw mandrel 40 passes through The thread is sleeved in the inside of the push plate 41, and the push plate 41 is slidably installed in the third chute.

[0029] working principle:

[0030] The first motor 3 drives the first screw mandrel 4 to rotate, and the first screw mandrel 4 drives the slider 14 to move through threads, the slider 14 drives the first connecting rod 15 to rotate, the first connecting rod 15 drives the first rotating shaft 17 to move, and the first connecting rod 15 drives the first rotating shaft 17 to move. A rotating shaft 17 drives the fine grinding wheel 18 to roll, and the slide block 14 drives the second connecting rod 16 to rotate, and the second connecting rod 16 drives the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com