Semi-dry desulfurization system suitable for low-sulfur flue gas

A semi-dry desulfurization and flue gas technology, used in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as hidden dangers of equipment operation, material collapse, single inlet, etc., to improve stability and reliability. , The effect of avoiding material collapse and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

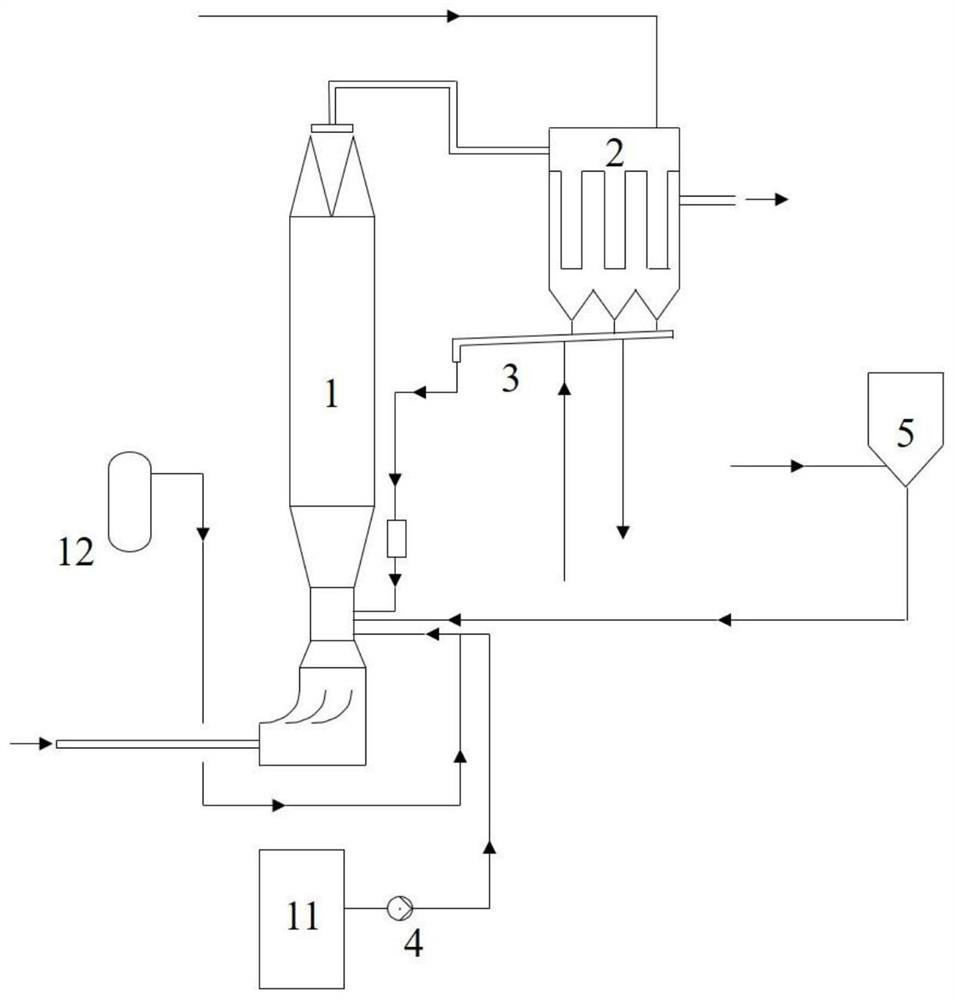

[0025] The invention provides a semi-dry desulfurization system suitable for low-sulfur flue gas. The system can meet the purification requirements of low-sulfur flue gas ultra-low emissions, simplify the system configuration, reduce the energy consumption of the desulfurization system, and improve the efficiency of desulfurization. System stability and reliability.

[0026] The invention provides a semi-dry desulfurization system suitable for low-sulfur flue gas, such as figure 1 As shown, the semi-dry desulfurization system includes a desulfurization absorption tower 1, a pulse-jet bag filter, a process water storage and delivery device, a desulfurization agent storage and delivery device, a desulfurization circulating ash delivery device, and a compressed air device;

[0027] There is no circulating fluidized bed in the desulfurization absorption tower 1;

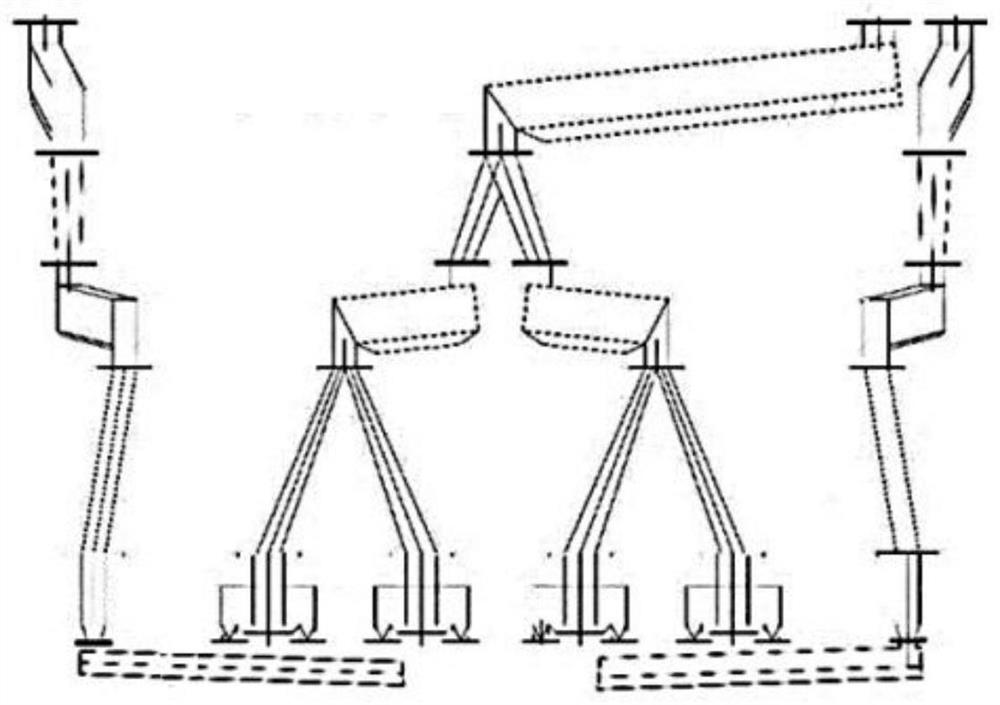

[0028] The desulfurization absorption tower 1 is provided with a Venturi structure;

[0029] The process water stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com