Manufacturing method of single-optical-fiber cascade type temperature-depth-salinity sensor for deep sea exploration

A production method and a single optical fiber technology, which are applied in the direction of transmitting sensing components, converting sensor output, and instruments with optical devices, can solve problems such as signal strength weakening, microstructure damage, and unfavorable high-efficiency mass production, and achieve compensation for optical transmission loss. , Simple preparation process, easy and efficient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

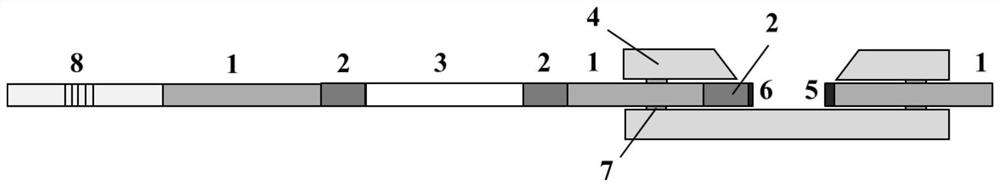

[0023] see figure 1 As shown, a single optical fiber cascaded temperature-depth-salinity sensor structure for deep-sea exploration, including optical fiber 1, optical fiber micro self-focusing lens 2, glass capillary 3, hollow glass tube 4, high reflection film 5, The semi-reflective film 6, the hydrogen-oxygen catalytic bonding solution 7, and the optical fiber grating 8 can simultaneously realize three-parameter sensing on the same optical fiber.

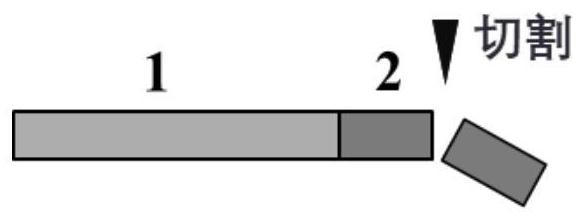

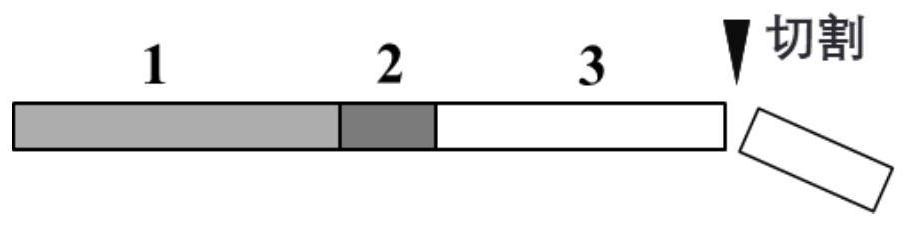

[0024] The optical fiber 1 is an ordinary single-mode optical fiber with a diameter of 125 μm and a core diameter of 9 μm; the optical fiber miniature self-focusing lens 2 is made by cutting a graded-index multimode optical fiber, the diameter of the graded-index multimode optical fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com