Special material frame for oxygen-free copper pipe annealing

An oxygen-free copper tube and annealing technology, used in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of micro-deformation, affecting product quality, and copper tubes are not easy to anneal, and achieve the effect of easy pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

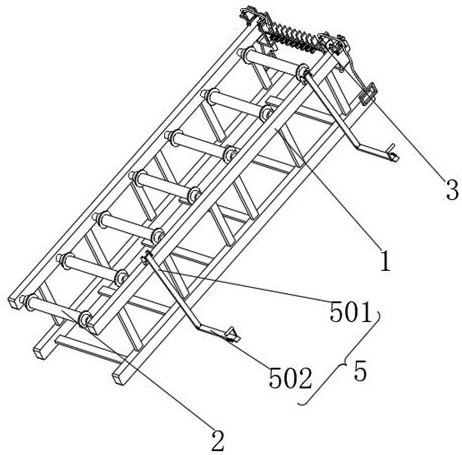

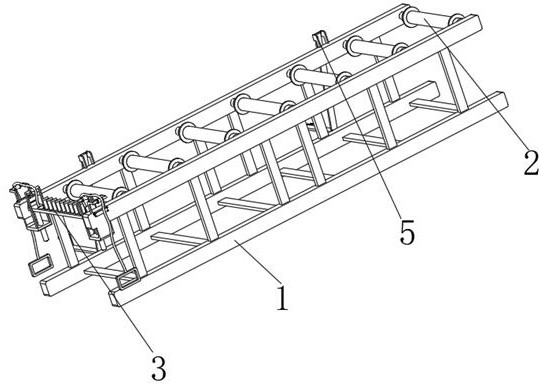

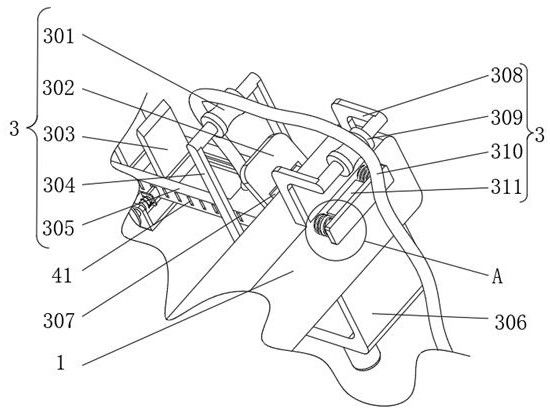

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a special material frame for oxygen-free copper tube annealing, including a frame 1 and a clamping device 3, the inner wall of the frame 1 is evenly rotated and connected with a roller 2, and the surface of the frame 1 is provided with a clamping device 3, The surface of the slider 314 is provided with an adjusting device 4 , and the surface of the frame 1 is provided with a feeding device 5 .

[0031] Let's talk about the specific settings and functions of the clamping device 3, the adjusting device 4 and the feeding device 5 in detail below.

[0032] like figure 1 and image 3As shown, the clamping device 3 includes two connecting plates 306, both of which are fixedly connected to the surface of the frame 1, and the connecting plates 306 are in an "L" shape structure, and the surfaces of the two connecting plates 306 are slidingly connected to a limited extent. Position rod 315, wherein the lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com