A Round Steel Rolling Process with Optimized Guide Configuration

A round steel rolling and process technology, which is applied in the field of round steel rolling technology with optimized guide configuration, can solve the problems of increasing the production cost of bar steel, long guide replacement time, more manpower and working hours, etc., and achieve the quality of finished products High, low carbon content, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

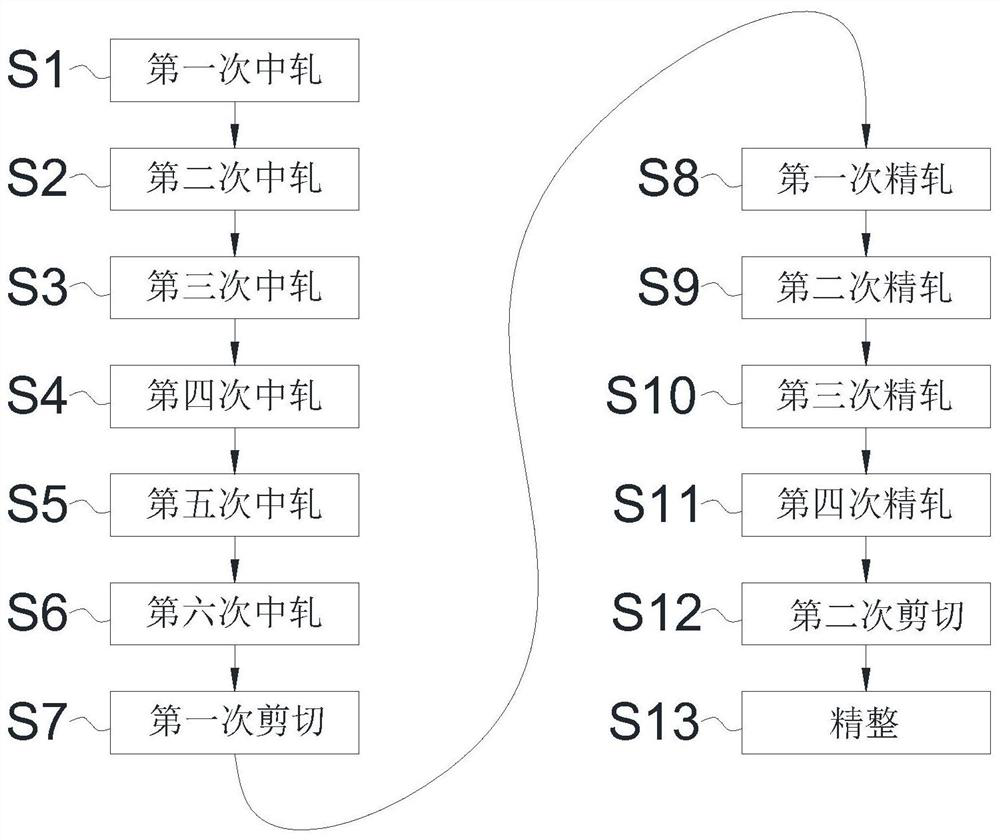

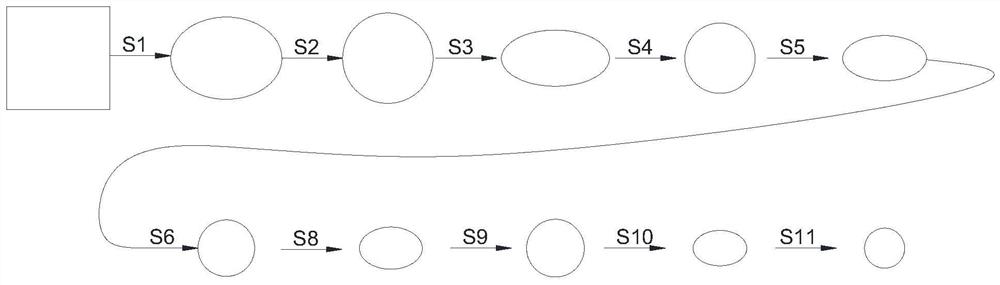

[0061] see Figure 1-Figure 3

[0062] What this embodiment provided was the rolling process of producing φ80 round steel. Specifically include the following steps:

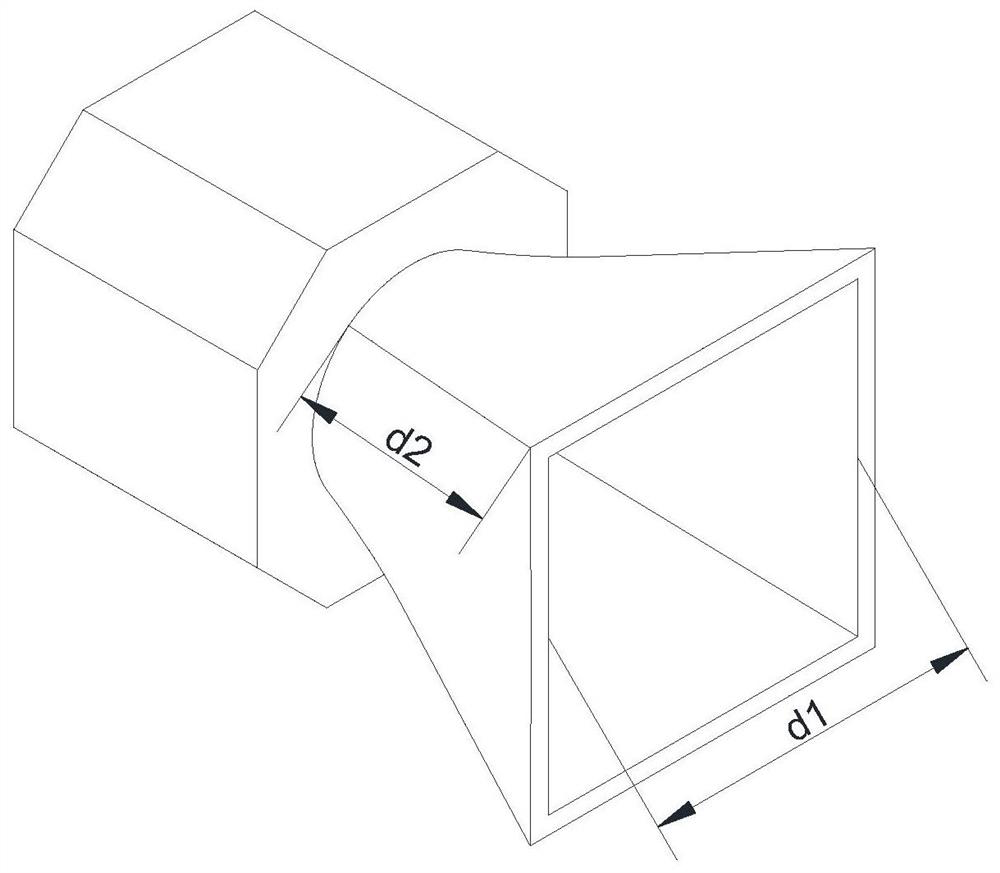

[0063] S1: For the first intermediate rolling, the incoming square steel with a size of 205mm×205mm is pushed into the first oval-gauge rolling mill for the first intermediate rolling. The reduction is 40mm per pass, and the square steel with a size of 205mm×205mm is The incoming material is rolled into a billet of 164mm×221mm, that is, the first intermediate rolling is completed; the roll diameter of the rolling mill in this intermediate rolling is 800mm, and the roll thickness between two adjacent rolls is 8.0mm. The elongation coefficient of each deformation pass is 1.26, the rolling speed is 0.27m / s, and the rolled area is 33413mm 2 ;

[0064] S2: In the second intermediate rolling, the billet with a size of 164mm×221mm formed in the first intermediate rolling is pushed into the first round-gauge rolling ...

Embodiment 2

[0084] see Figure 1-Figure 3

[0085] What this embodiment provided was the rolling process of producing φ90mm round steel. Specifically include the following steps:

[0086]S1: For the first intermediate rolling, the incoming square steel with a size of 205mm×205mm is pushed into the first oval-gauge rolling mill for the first intermediate rolling. The reduction is 40mm per pass, and the square steel with a size of 205mm×205mm is The incoming material is rolled into a billet of 164mm×221mm, that is, the first intermediate rolling is completed; the roll diameter of the rolling mill in this intermediate rolling is 800mm, and the roll thickness between two adjacent rolls is 8.0mm. The elongation coefficient of each deformation pass is 1.26, the rolling speed is 0.27m / s, and the rolled area is 33413mm 2 ;

[0087] S2: In the second intermediate rolling, the billet with a size of 164mm×221mm formed in the first intermediate rolling is pushed into the first round-gauge rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com