Deslagging device of fan coal mill

A technology of fan coal mill and weighing device, which is applied in the field of machinery, can solve the problems of increasing the wear of components such as the impact wheel, and the slag of the fan coal mill cannot be discharged in time, so as to achieve the effect of easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

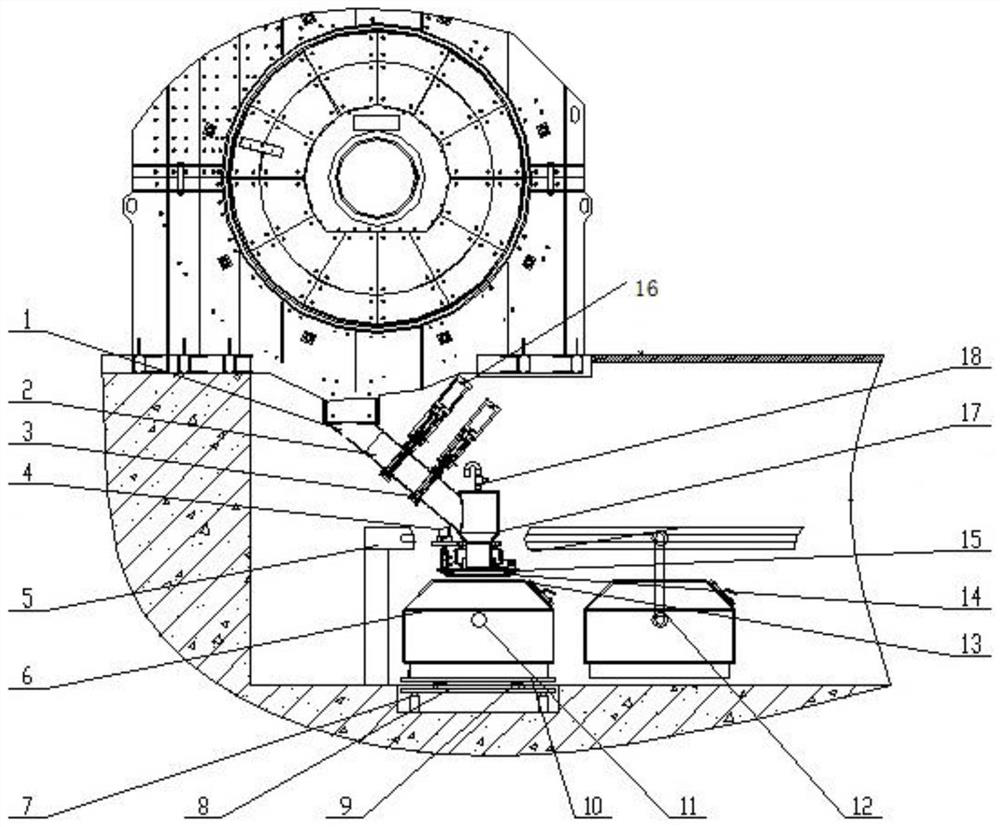

[0019] see figure 1 , the present invention provides a technical solution: see figure 1 , the slag discharge device of the fan coal mill of the present invention includes a pipe with different diameters and a slag discharge pipe 2 connected to the bottom of the iron accumulation tank of the casing 1, and the slag discharge pipe 2 is provided with two pneumatic shut-off valves, from top to bottom, Respectively referred to as the primary shut-off valve 16 and the secondary shut-off gate valve 3, the tail end of the slag discharge pipeline 2 is connected to the sealed cabin 17, and the top end of the sealed cabin 17 is provided with a pressure relief valve 18, and the lower end is connected to the protective cover 15 and the sealing ring 14, and the sealing The outside of the cabin 17 is provided with a compression cylinder 4 for squeezing the sealing ring 14 for sealing. Below the sealing ring 14 is a transfer box 6 with an observation window 13. The transfer box 6 is installed ...

Embodiment 2

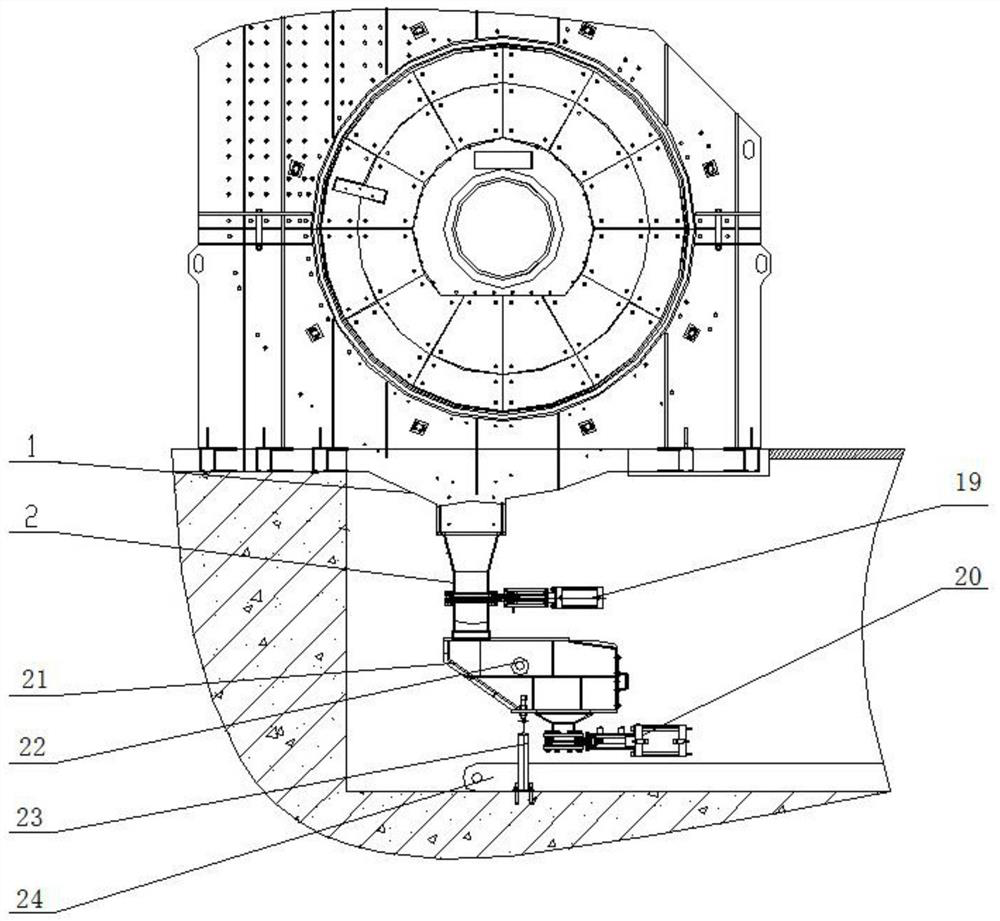

[0022] refer to figure 2 , the slagging device of the fan coal mill of the present invention comprises a different-diameter pipeline 1 and a slag discharge pipeline 2 connected to the lower iron tank of the casing 1, the slag discharge pipeline 2 is provided with a first pneumatic shut-off valve 19, and the slag discharge The lower end of the pipeline 2 is connected to the pebble coal storage box 21, and the pebble coal storage box 21 is provided with a material level gauge 22, and the box body is fixed on the ground through a support seat 23, and a second pneumatic shut-off valve 20 is provided under the box body, and the transfer device is Pebble coal conveyor belt24.

[0023] The working process of the present invention is: when the coal mill is running, the first pneumatic shut-off valve 19 on the slag discharge pipeline 2 is opened, the second pneumatic shut-off valve 20 is closed, and the slag material discharged from the coal mill is stored in the gravel In the coal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com