[0009] When working, because in the prior art, a baffle is usually used to block one eye for a

monocular vision test when performing a

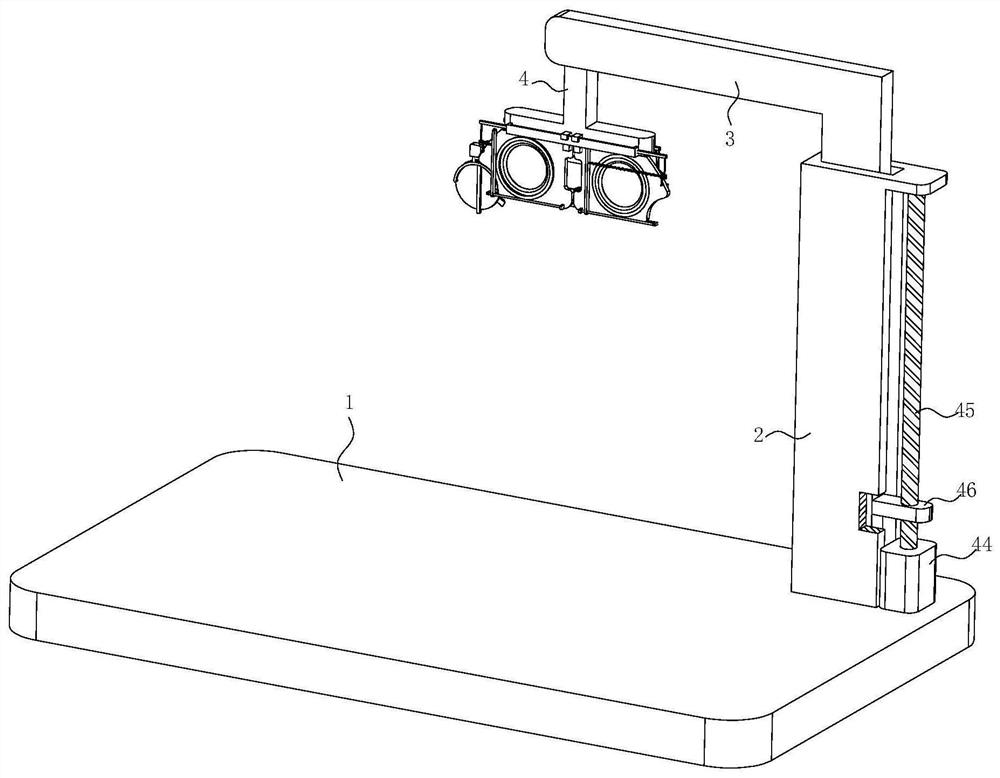

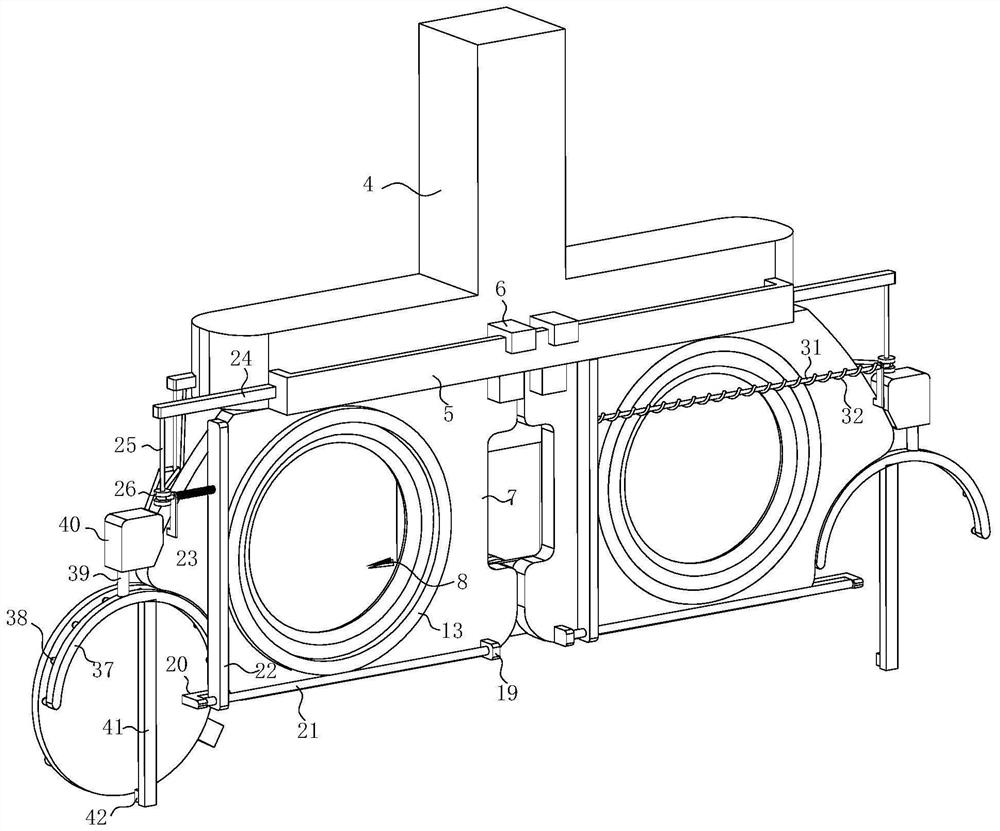

visual inspection, but the baffle is held by the inspector for inspection each time, so that when the baffle is easily blocked, the Offset, the baffle cannot completely cover one eye, making the detection result of the single eye inaccurate and affecting the detection result. The present invention provides a technical solution to solve the above problems. When the present invention is used, the two baffles are in the near To detect the state of through-hole shielding, the person to be detected steps on the top of the bottom plate, adjust the driving mechanism so that the L-shaped lifting plate, T-shaped fixed plate and installation plate are within the eye range of the inspector, and cooperate with the person to carry out simple movement, so that the waiting The human eyes of the person to be detected are in the position facing the two detection through holes, and the two baffle plates and the mounting plate completely shield the person to be detected, so as to avoid the interference of the other eye during the single-

eye detection, and then start the

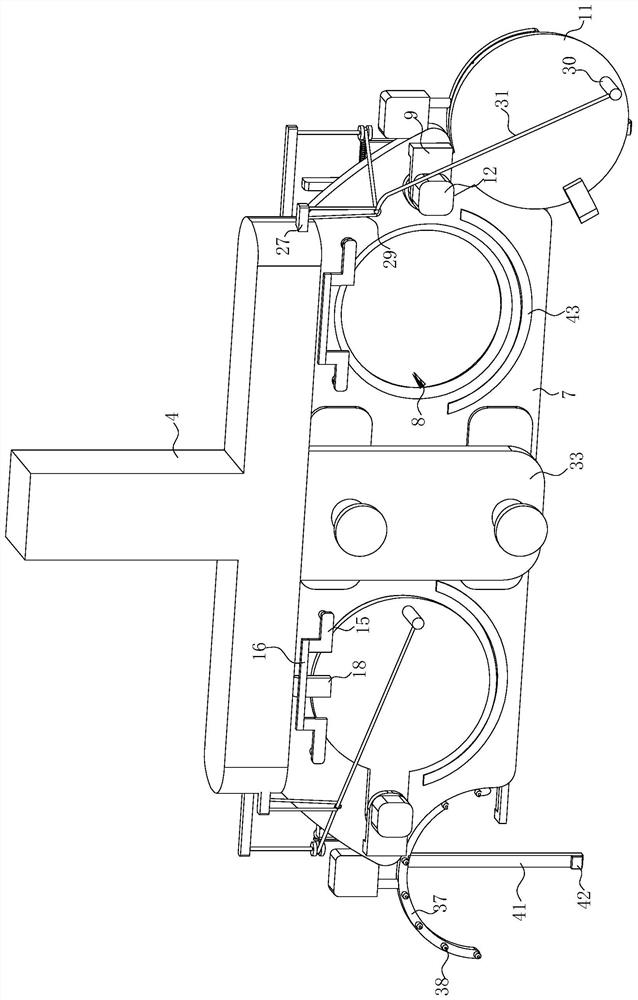

visual inspection For detection, start the first motor on one side first, and the first motor drives the first rotating rod and the shielding plate to rotate, so that the shielding plate slowly breaks away from the shielding detection through hole. During the rotation of the shielding plate, it drives the first guide block fixedly connected with it Rotate at the same time, so that the first guide block is slowly separated from the push plate, and the push plate, the first slide bar and the arc-shaped protective plate slowly slide forward under the pull of the first spring, so that the arc-shaped protective plate protrudes from the mounting plate, avoiding waiting The face of the inspected personnel is completely attached to the front surface of the mounting plate, as far as possible to ensure that the personnel are not in contact with the mounting plate, to ensure the cleanliness of the mounting plate, to avoid stains on the mounting plate after repeated use, and during the rotation of the shielding plate, The blocking plate pulls the pull

rope through the fixed column. After the pull

rope is guided by the U-shaped guide frame and the first guide wheel, it pulls the cleaning scraper. When the arc-shaped protective plate is used, the arc-shaped protective plate cannot protrude from the mounting plate, and the plane formed by the arc-shaped protective plate and the mounting plate is in full contact with the cleaning scraper. During the rotation of the shielding plate, the cleaning scraper is pulled by the pull cord to the outside of the mounting plate Move, scrape and clean the arc-shaped protective plate and the installation plate once, the L-shaped blocking plate hinders the second spring, and compress the second spring during the movement of the cleaning scraper to the outside, cleaning the bottom of the scraper and the installation plate at the same time position, so that the cleaning scraper moves close to the front surface of the installation plate under the pull of the pull

rope. Break away from the pushing plate, when the cleaning scraper breaks away from the arc protection, the pushing plate, the first slide bar and the arc protection plate slowly slide forward under the pull of the first spring, so that the arc protection plate protrudes from the installation plate, avoiding The face of the person to be detected is completely attached to the front surface of the mounting plate. Try to ensure that the personnel do not touch the mounting plate, keep the mounting plate clean, and avoid stains on the mounting plate after multiple uses. However, after the detection of one eye is completed , the first motor starts to reverse, so that the blocking plate is slowly reset, and the pull rope is released, but at this time, the cleaning scraper is blocked by the arc protective plate and cannot be reset. When the blocking plate is completely reset, the first guide block on the blocking Press the pushing plate so that the pushing plate, the first sliding rod and the arc-shaped protective plate are retracted into the mounting plate again, and then, under the action of the second spring, the cleaning scraper moves to the inner side of the mounting plate along the polished rod and the mounting plate, In the same way, the other

eye detection is carried out, so that each time a person needs to be tested for vision, the installation plate and the shielding plate are used to completely cover the eyes of the person with the detection, so as to avoid the phenomenon of incomplete

occlusion during single-eye detection and ensure The accuracy of single-eye detection, and during detection, when the shielding plate is rotated, the cleaning scraper can clean the installation plate and the arc-shaped protective plate in advance before the detection, so as to avoid the stains left by the previous detection personnel from interfering with the detection, and After the cleaning scraper is cleaned, make the arc-shaped protective plate protrude from the mounting plate to prevent the face of the person to be detected from completely fitting on the front surface of the mounting plate, as far as possible to ensure that the personnel do not touch the mounting plate, ensure the cleanliness of the mounting plate, and avoid After repeated use, the mounting plate will adhere to stains, which is beneficial for personnel to perform visual inspection

Login to View More

Login to View More  Login to View More

Login to View More