Eyesight testing device

A vision detection and eye technology, which is applied in the direction of eye testing equipment, medical science, diagnosis, etc., can solve the problems of eye chart damage and difficult adjustment, and achieve the effect of easy use and vision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

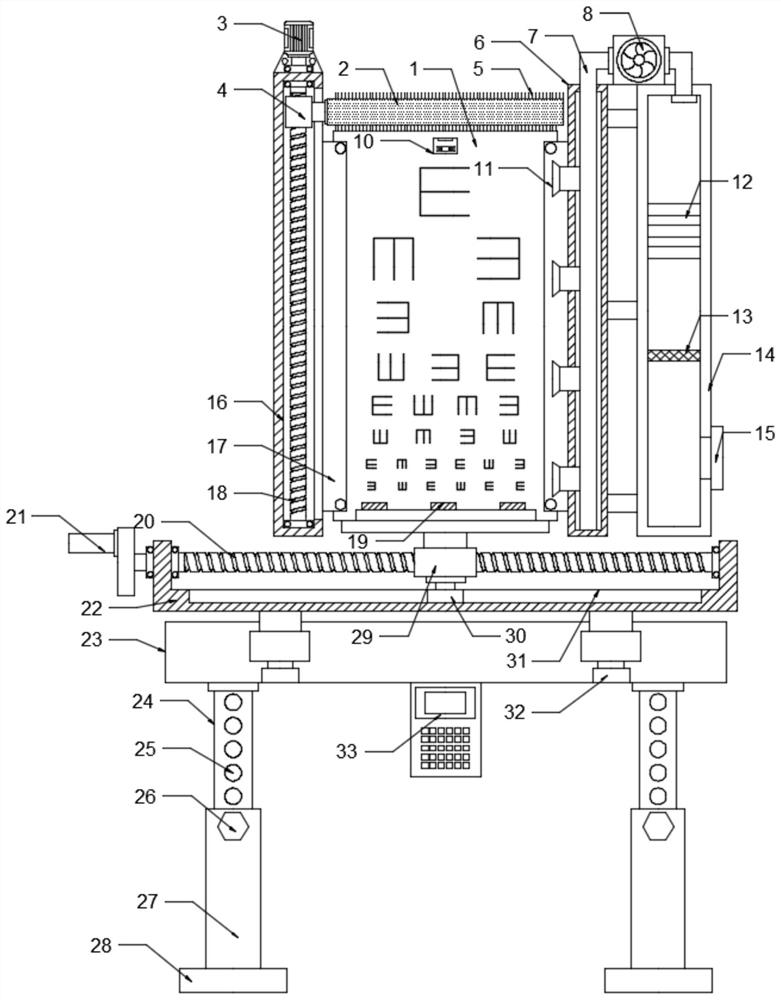

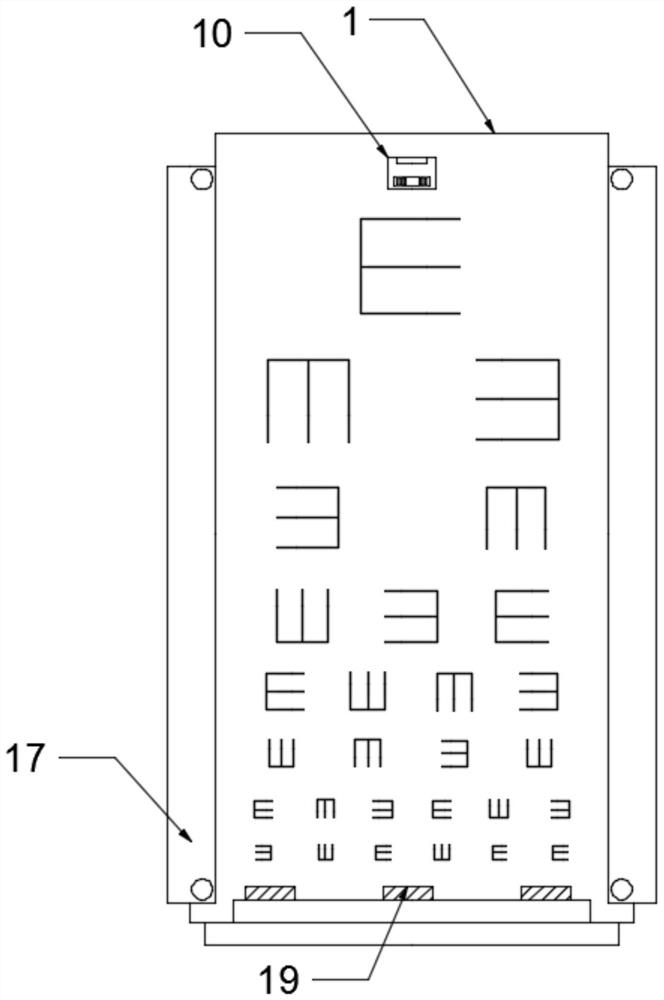

[0021] see Figure 1-2 , a kind of eyesight detection device, comprises vision detection table 1 and adjusting box 22, described vision detection table 1 left side is provided with lifting box 16, and screw rod one 18 is set in described lifting box body 16, and described screw rod one 18 and The inner wall of the lifting box 16 is rotationally connected, the surface of the screw rod-18 is provided with a nut-4, and the nut-4 can move up and down in the vertical direction with the rotation of the screw rod-18, and the upper surface of the top wall of the lifting box body 16 is provided with a nut-4. Drive motor 3, described drive motor 3 is fixedly connected with lifting box body 16 top walls, and described drive motor 3 output end passes through lifting box body 16 and is fixedly connected with screw rod one 18, and described nut one 4 is connected with rotating roller by connecting rod 2 rotating connection, the surface of the rotating roller 2 is equidistantly provided with...

Embodiment 2

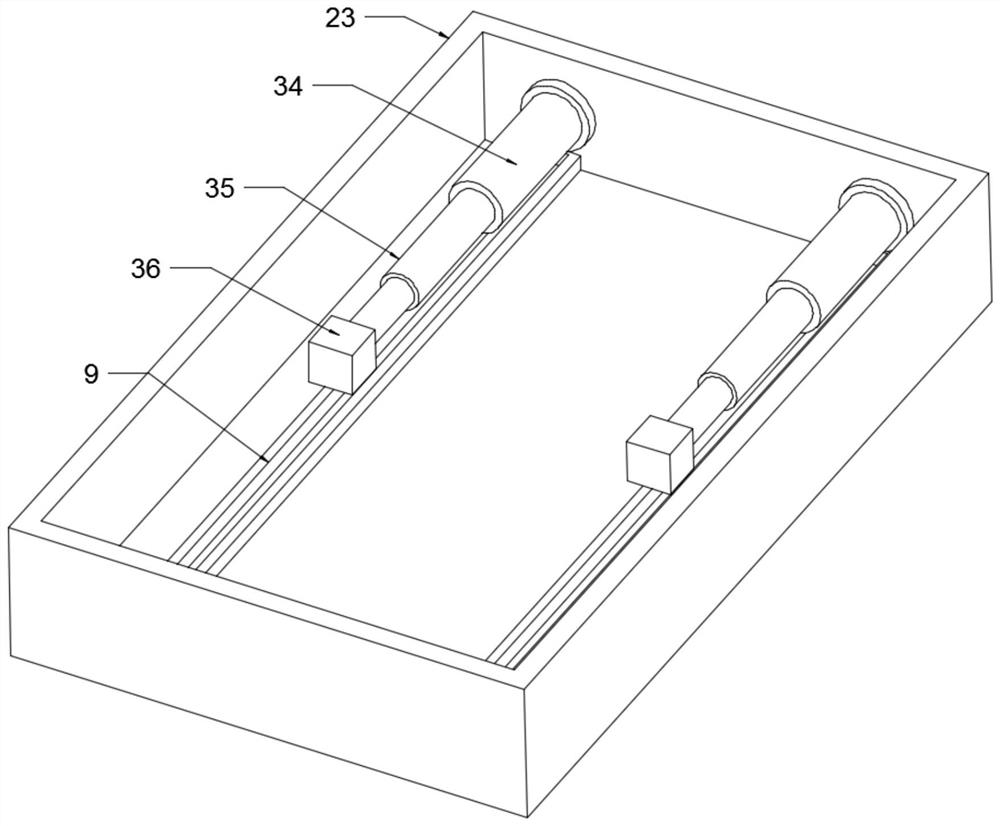

[0027] see Figure 1-3 , on the basis of Embodiment 1, in order to adjust the position of the visual acuity test meter 1, screw rod 2 20 is set in the described adjustment box 22, and described screw rod 2 20 is connected with the inner wall of adjustment box 22 by rotation, and the surface of the described screw rod 2 20 is Nut 2 29 is set, and described nut 2 29 can move left and right in the horizontal direction along with the rotation of screw rod 2 20. The left end of the screw rod 20 passes through the adjustment box 22 to extend and fix the connection handle 21. The bottom of the visual acuity test table 1 is fixedly connected, and by turning the handle 21, the handle 21 drives the screw rod 220 to rotate, and the nut two 29 drives the visual acuity test table 1 to move left and right in the horizontal direction to adjust its horizontal position. 22, a drive box 23 is arranged below, and a hydraulic cylinder 34 is arranged symmetrically in the drive box 23, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com