Anti-falling fastener-free cable mounting plate device

A fastener and anti-falling technology, which is applied in the direction of cable installation device, cable installation, busbar/line layout, etc., can solve the problems of narrow space for free operation, increased operation difficulty, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

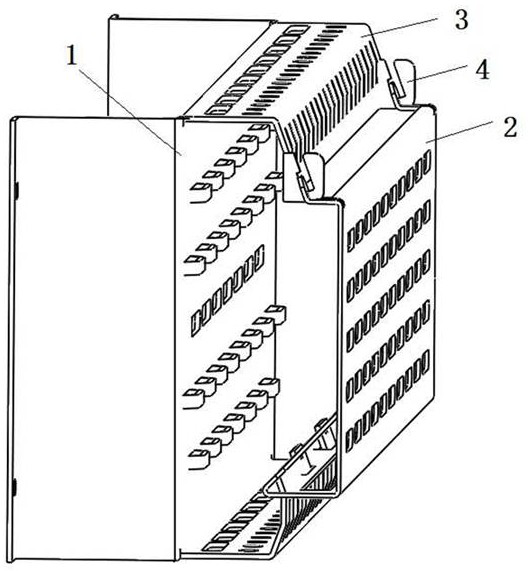

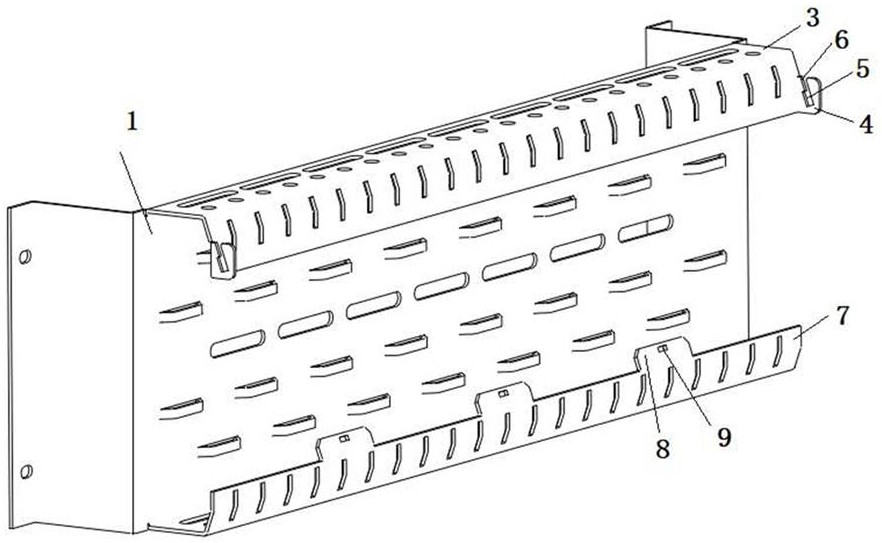

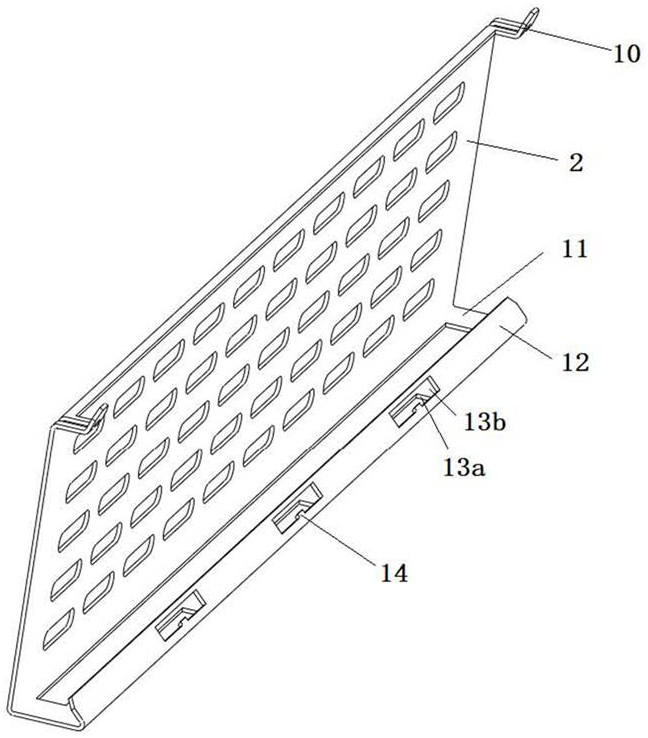

Embodiment 1

[0028] A cable mounting device for preventing falling off and free of fasteners, comprising a mounting plate 1, a cover plate 2, a mounting plate flange 3, a hook 4, a chute 5, a limiting boss 6, and a mounting plate lower flange 7 , inserting plate 8, clamping hole 9, hanging ring 10, flat lower flange plate 11 of cover plate, inclined plate 12 of lower flange of cover plate, first socket 13a, second socket 13b, post 14, chute 5 width 3.5 mm, limit boss 6 height 1.2mm, insert plate 8 length, width and height 38mm / 8mm / 1.5mm, card hole 9 length, width and height 6mm / 2mm / 1.5mm, hanging ring 10 thickness 1.2mm, first socket 13a length and width The height is 41mm / 5mm / 1.2mm, the length, width, and height of the second socket 13b are 41mm / 5mm / 1.2mm, and the length, width, and height of the post 14 are 5mm / 1.2mm / 1.2mm. The above dimensions can be enlarged or reduced in equal proportions, as long as they are set according to the above structure , can realize the function of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com