Wire clamp cleaning and conductive paste smearing integrated processing device

A processing device and conductive paste technology, applied in the direction of circuit/collector parts, circuits, electrical components, etc., can solve the problems of low efficiency, irregular construction, labor consumption, etc., to solve low efficiency, improve maintenance efficiency, Improve the effect of smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

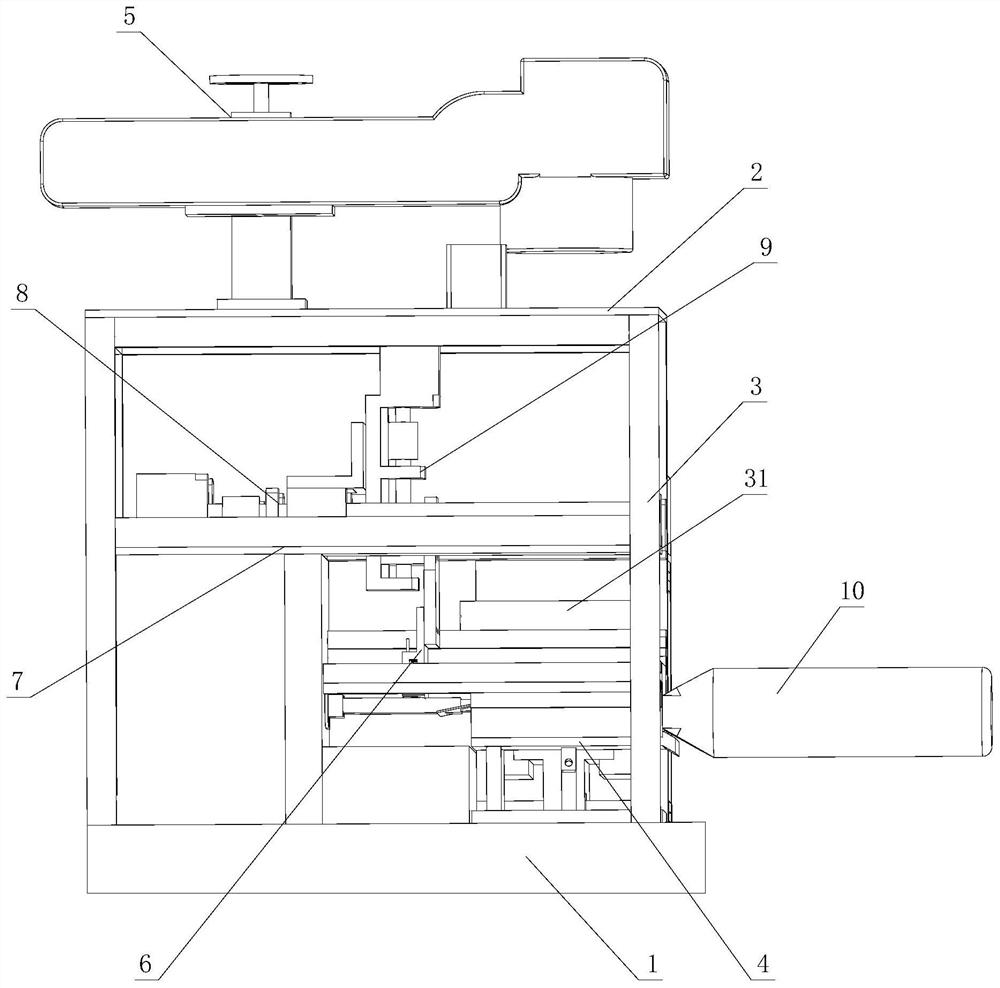

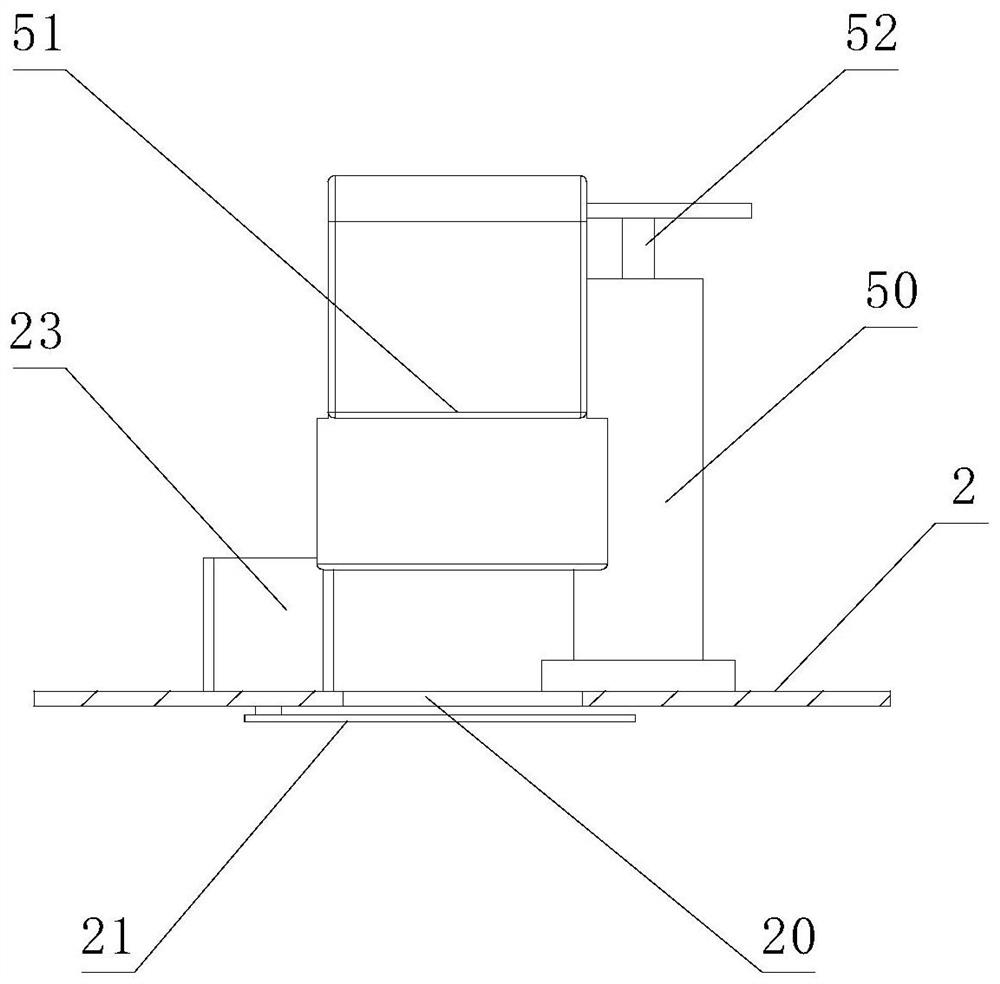

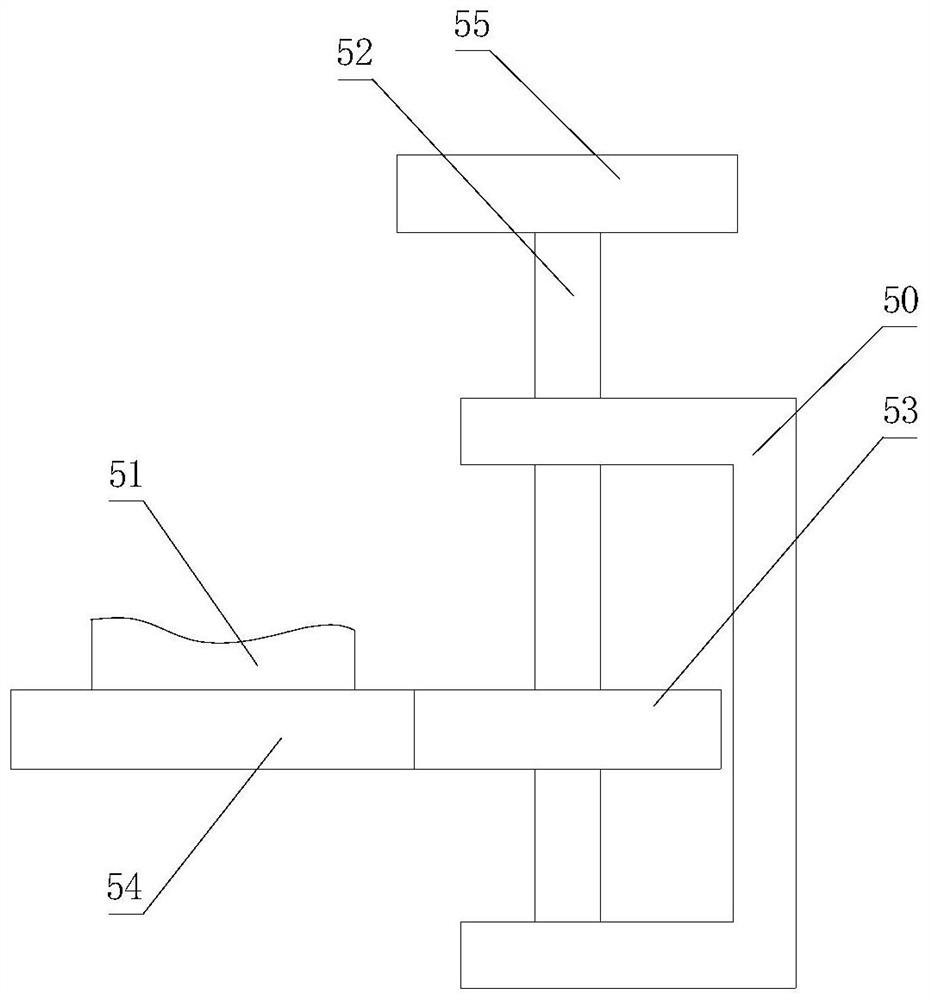

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the integrated processing device for wire clamp cleaning and conductive paste application includes a bottom plate 1, a top plate 2 and a connecting rod 3 arranged between the bottom plate 1 and the top plate 2, and the bottom plate 1 is provided with a clamping mechanism for fixing the wire clamp 4. The top plate 2 is provided with a laser cleaning part 5 and an irradiation hole 20 for laser irradiation. The connecting rod 3 is movably connected with a feeding mechanism 6 for spraying conductive paste to the wire clip, and the feeding mechanism 6 is located at Between the clamping mechanism 4 and the top plate 2, the bottom end of the feeding mechanism 6 is provided with a scraper 60 that evenly coats the conductive paste on the wire clamp, and the feeding mechanism 6 is provided with a device for dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com