Manual-automatic integrated electric vehicle speed change system and use method thereof

An electric vehicle, an integrated technology, applied in the direction of control/regulation system, transmission control, and components with teeth, etc., can solve problems such as large volume, gear impact, and unstable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

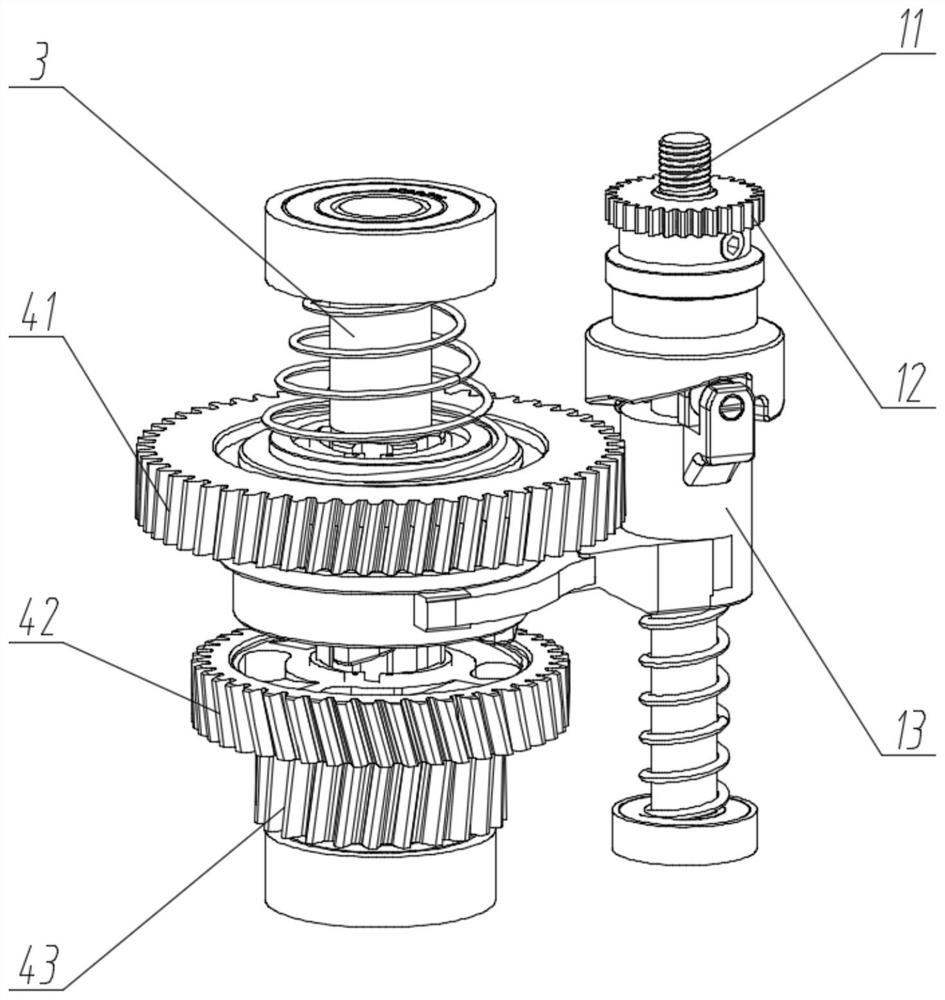

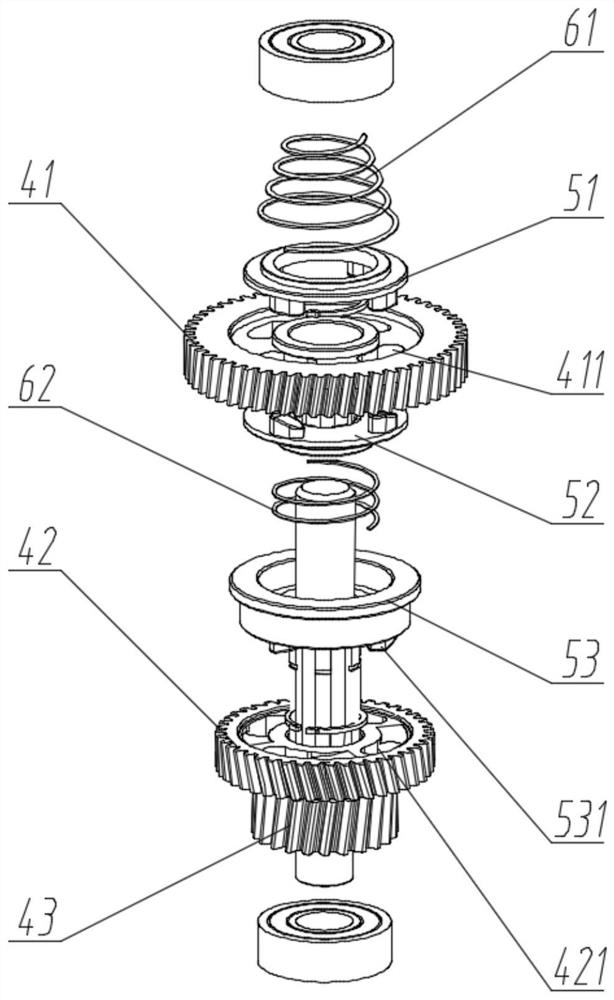

[0058] like figure 1 , figure 2 , image 3 As shown, this manual-integrated transmission system for electric vehicles includes a transmission device and a shifting fork device,

[0059] The speed change device includes a transmission shaft 3, a gear assembly and a claw plate assembly;

[0060] The transmission shaft 3 is rotatably mounted on the casing;

[0061] The gear assembly includes a slow gear 41, a fast gear 42 and an output gear 43 that are sequentially arranged on the transmission shaft 3 from top to bottom. The slow gear 41 and the fast gear 42 are sleeved and axially limited, and the output gear 43 fixed settings;

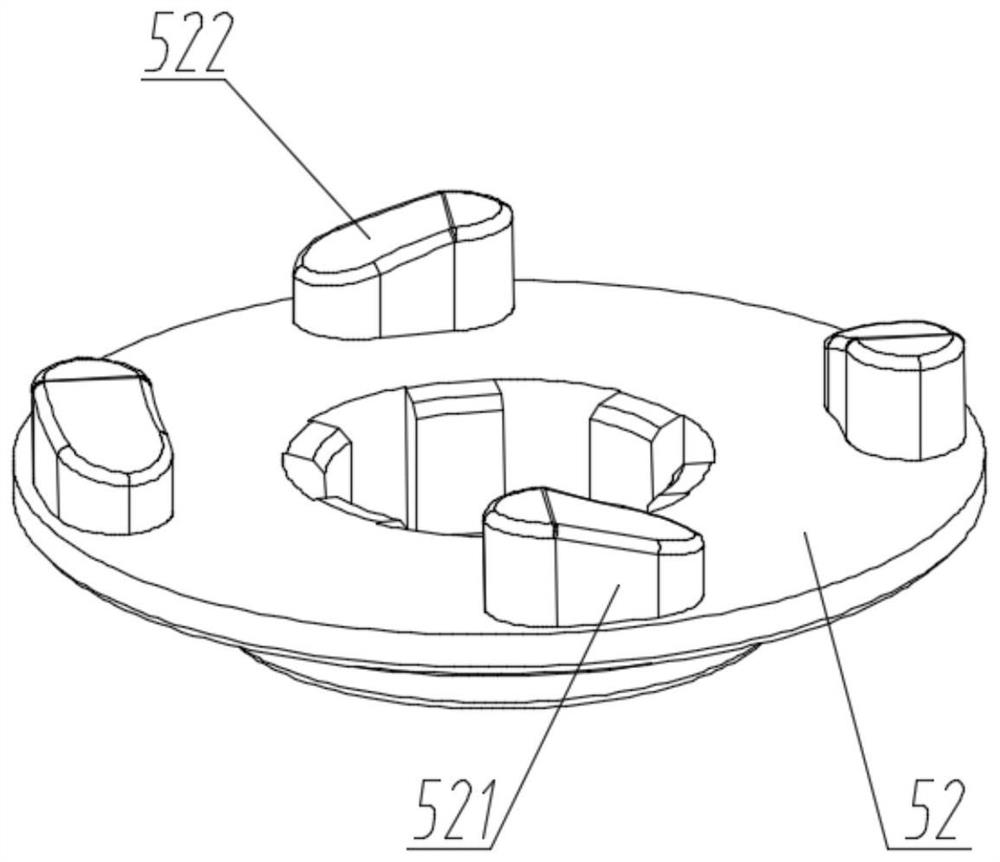

[0062] The slow gear 41 is provided with a plurality of circumferentially arranged first through holes 411; preferably, the shape of the first through holes 411 is a U-shaped hole structure;

[0063] The claw plate assembly is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com