Special acid and alkali resistant fabric for special clothing

A technology of acid and alkali resistance and fabrics, which is applied in the field of fabrics, can solve the problems that fabrics cannot meet, and achieve the effects of improved roughness, simple operation, and excellent electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

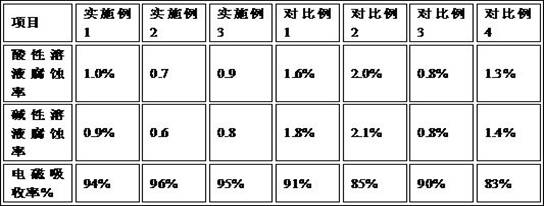

Examples

Embodiment 1

[0046] A processing technology for special acid and alkali resistant fabrics for special clothing, comprising the following steps:

[0047] (1) Prepare raw materials;

[0048] (2) Take barium chloride dihydrate, zinc chloride, ferric chloride hexahydrate and urea, add deionized water and ethylene glycol after mixing, continue to stir until dissolved, oscillate ultrasonically for 20 minutes, and then place in a high-pressure reactor , sealed and reacted at 170°C for 3h, cooled to room temperature, centrifuged, washed and dried, dried and placed in a nitrogen environment, calcined at 550°C for 2h to obtain material A;

[0049] (3) Take carbon nanotubes and deionized water, ultrasonically oscillate for 20 minutes, add Tris solution, dilute hydrochloric acid to adjust the pH to 8, then add dopamine and material A, stir and react at 25°C for 10h, filter and wash, and dry at a constant temperature of 60°C. get magnetic material;

[0050] (4) Take the magnetic material and toluene,...

Embodiment 2

[0056] A processing technology for special acid and alkali resistant fabrics for special clothing, comprising the following steps:

[0057] (1) Prepare raw materials;

[0058] (2) Take barium chloride dihydrate, zinc chloride, ferric chloride hexahydrate and urea, mix them, add deionized water and ethylene glycol, continue to stir until dissolved, oscillate ultrasonically for 25 minutes, and then place them in a high-pressure reactor , sealed and reacted at 175°C for 4h, cooled to room temperature, centrifuged, washed and dried, dried and placed in a nitrogen environment, calcined at 555°C for 2.2h to obtain material A;

[0059] (3) Take carbon nanotubes and deionized water, ultrasonically oscillate for 25 minutes, add Tris solution, adjust the pH to 8.5 with dilute hydrochloric acid, then add dopamine and material A, stir and react at 27°C for 11h, filter and wash, and dry at a constant temperature of 60°C. get magnetic material;

[0060] (4) Take the magnetic material and ...

Embodiment 3

[0066] A processing technology for special acid and alkali resistant fabrics for special clothing, comprising the following steps:

[0067] (1) Prepare raw materials;

[0068] (2) Take barium chloride dihydrate, zinc chloride, ferric chloride hexahydrate and urea, add deionized water and ethylene glycol after mixing, continue to stir until dissolved, oscillate ultrasonically for 30 minutes, and then place in a high-pressure reactor , sealed and reacted at 180°C for 5h, cooled to room temperature, centrifuged, washed and dried, dried and placed in a nitrogen environment, and calcined at 560°C for 2.5h to obtain material A;

[0069] (3) Take carbon nanotubes and deionized water, ultrasonically oscillate for 30 minutes, add Tris solution, dilute hydrochloric acid to adjust the pH to 9, then add dopamine and material A, stir and react at 28°C for 12h, filter and wash, and dry at a constant temperature of 60°C. get magnetic material;

[0070] (4) Take the magnetic material and to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com