Leather printing and dyeing process

A printing and dyeing process, leather technology, applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc., can solve problems such as uneven dyeing of leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

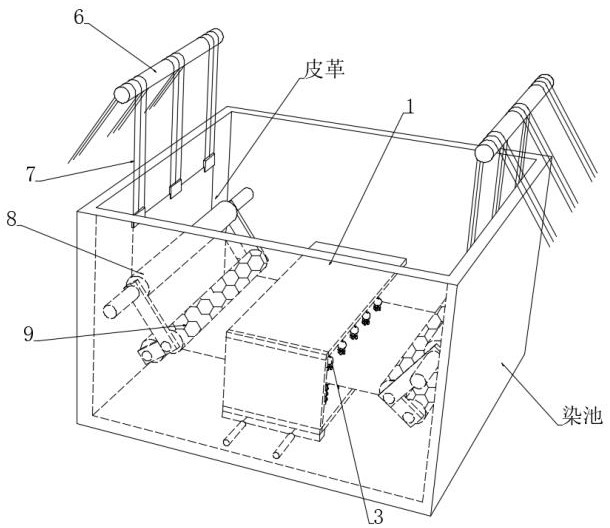

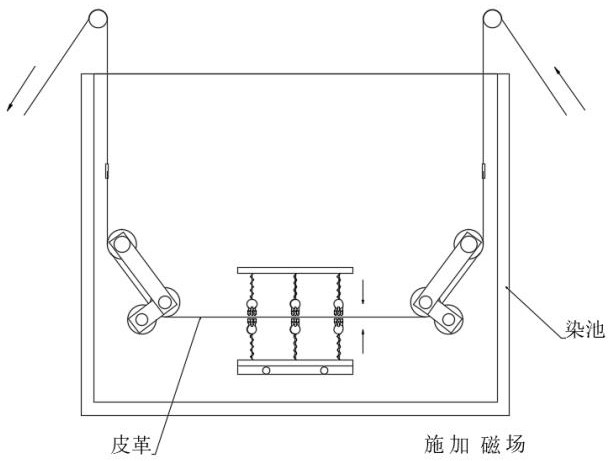

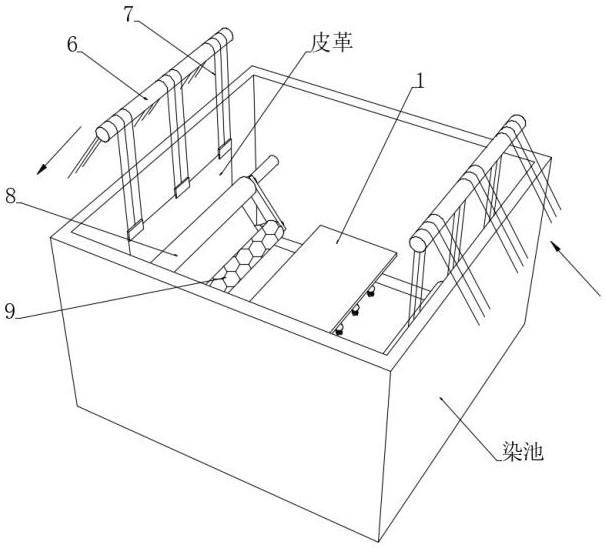

[0039] see Figure 1-2 , take the leather and soak it in pure water for 1-1.5h, wash the soaked leather with water, and then steam the washed leather for 0.5-1h, install the leather winding parts in the dyeing pool loaded with dye, The leather is pulled left and right by leather winding parts, and a pair of moving plates 1 distributed above and below the leather are arranged inside the dyeing pool. A magnetic field is applied to attract the upper elastic extrusion and repel the lower elastic extrusion, forcing the upper and lower elastic extrusions to squeeze the upper and lower ends of the leather, and the elastic extrusion absorbs the dye when it contacts the leather When extruded, the air will be released on the end of the leather to promote the dye to penetrate into the cracks of the leather. Repeatedly start and cut off the magnetic field to realize multiple extrusion operations, and cooperate with the leather to move back and forth on the leather winding piece. After dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com