Frosted velvet fabric and post-treatment process thereof

A fabric and sand fleece technology, applied in the field of frosted fleece fabrics and their post-processing technology, can solve the problems of easy to appear down-smooth, poor smoothness, easy to form touch marks, etc. The effect of the hair down phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

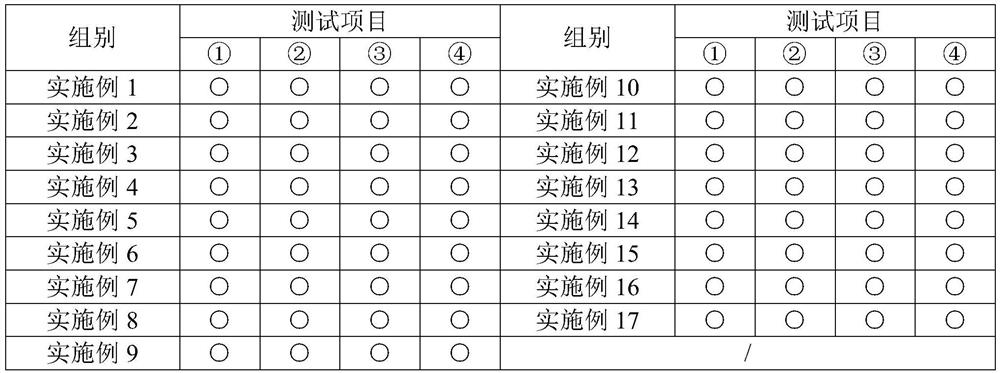

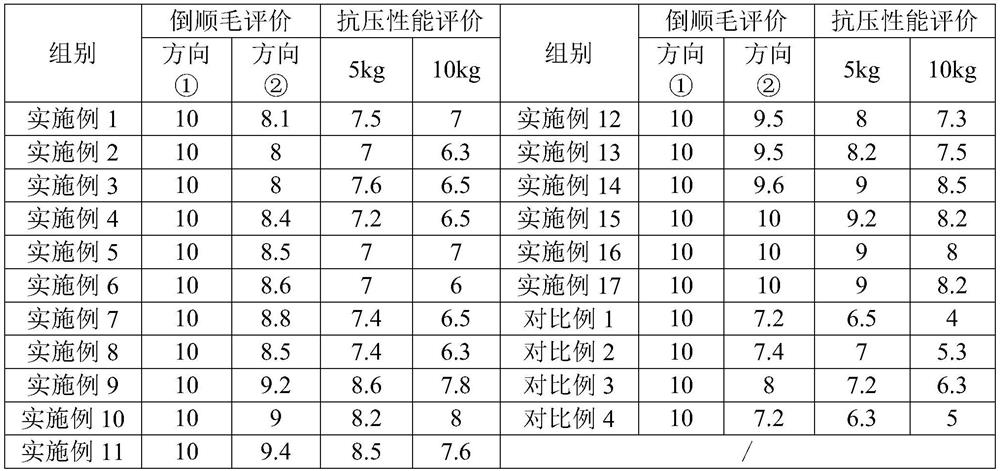

Examples

Embodiment 1

[0043] Embodiment 1: A kind of post-treatment process of frosted velvet fabric. The frosted velvet fabric is made of surface layer, middle layer and bottom layer through segmental warping and multi-comb weaving to form gray cloth. The surface layer adopts FDY polyester yarn 75D / 144F as raw material. The head pattern is 3000 threads / m, which is woven with a 45 / 10 structure; the middle layer is made of FDY polyester yarn 45D / 24F, and its head pattern is 3000 threads / m, which is woven with a 12 / 10 structure; the bottom layer is made of FDY polyester Silk 45D / 24F is used as the raw material, and its head pattern is 2500 threads / m, which is obtained by weaving with a structure of 10 / 23. The total thickness of the fabric gray cloth is 1cm, wherein the thickness of the surface layer is 40% of the total thickness of the fabric, and the thickness of the middle layer and the bottom layer are the same.

[0044] The post-processing process includes the following steps:

[0045] S1: Preli...

Embodiment 2

[0051] Example 2: A post-treatment process for a frosted velvet fabric. The frosted velvet fabric is composed of a surface layer, a middle layer and a bottom layer. The surface layer uses FDY polyester yarn 75D / 144F as a raw material, and its head pattern is 2800 threads / m, using 45 / 10 structure weaving; the middle layer is made of FDY polyester yarn 45D / 24F, and its head grain is 2800 threads / m, and it is woven with a 12 / 10 structure; the bottom layer is made of FDY polyester yarn 45D / 24F, and its head grain It is 2800 threads / m, obtained by weaving with a structure of 10 / 23. Wherein the thickness of the surface layer is 50% of the total thickness of the fabric, and the thickness of the middle layer and the bottom layer are the same.

[0052] The post-processing process includes the following steps:

[0053] S1: Preliminary setting: Send the fabric into a high-temperature oven and heat it at 230°C for 3 hours to complete the preliminary setting;

[0054] S2: Raising: Use t...

Embodiment 3

[0059]Embodiment 3: A kind of post-treatment process of frosted velvet fabric. The frosted velvet fabric is composed of surface layer, middle layer and bottom layer. The surface layer uses FDY polyester yarn 75D / 144F as raw material, and its head pattern is 2500 threads / m. / 10 structure weaving; the middle layer is made of FDY polyester yarn 45D / 24F, and its head pattern is 2500 threads / m, and it is woven with a 12 / 10 structure; the bottom layer is made of FDY polyester yarn 45D / 24F, and its head pattern It is 3000 threads / m, obtained by weaving with a structure of 10 / 23. Wherein the thickness of the surface layer is 70% of the total thickness of the fabric, and the thickness of the middle layer and the bottom layer are the same.

[0060] The post-processing process includes the following steps:

[0061] S1: Preliminary setting: send the fabric into a high-temperature oven, heat it at 240°C for 3 hours, and then complete the preliminary setting;

[0062] S2: Raising: Use 5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com