Preparation method of chitin natural colored cotton blended yarn

A technology of blended yarn and chitin, which is applied in yarn, textile, papermaking, biochemical fiber treatment, etc., can solve the problems of poor antibacterial properties of blended yarn, achieve soft color, reduce pollution, and improve antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

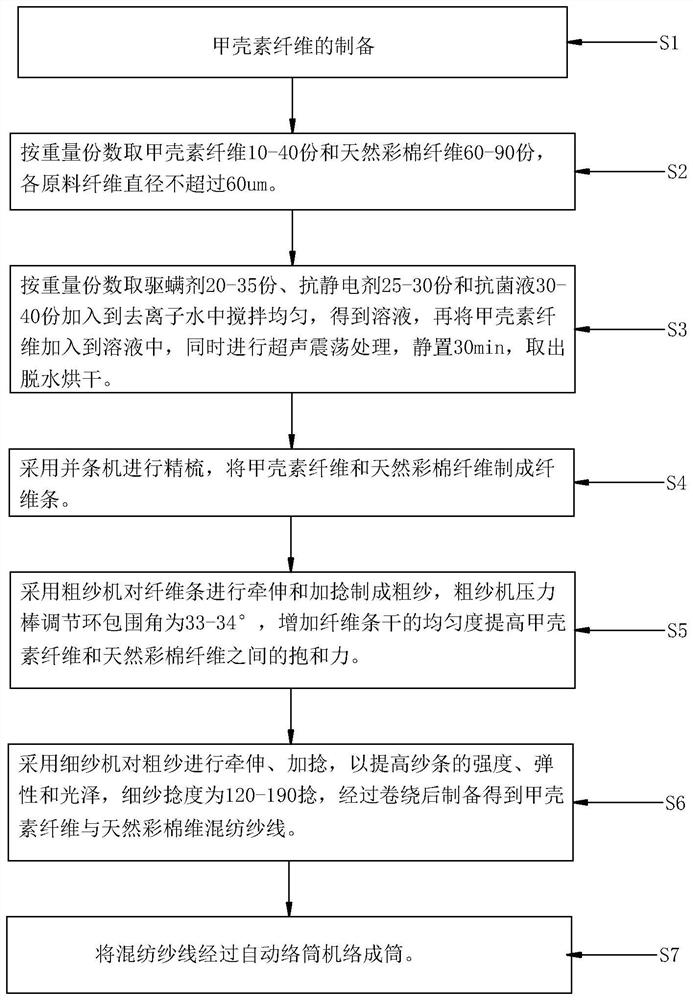

[0032] like figure 1 As shown, a method of preparing a chitin natural color cotton mixed yarn in accordance with an embodiment of the present invention includes the following steps:

[0033] S1: Preparation of Chin Fiber:

[0034] S2: 10 parts by weight of 10 parts by weight and 60 parts of natural color cotton fiber, and each raw material fiber is not more than 60 um.

[0035] S3: 20 parts by weight of the weight, 25 parts of the antistatic agent and 30 parts of the antibacterial liquid are added to the deionized water, and the solution is obtained, and the china fiber and natural cotton fibers are added to the solution, while performing Ultrasonic oscillating treatment, standing for 30 mi n, removing dehydration drying.

[0036] S4: combed with a strip to make a fibrous strip with a sage fiber and a natural color cotton fiber.

[0037] S5: The fibrous strip is drawn and twisted by the roving machine, and the coarse spinning machine pressure rod regulating the ring is 33 °, incre...

Embodiment 2

[0050] like figure 1 As shown, a method of preparing a chitin natural color cotton mixed yarn in accordance with an embodiment of the present invention includes the following steps:

[0051] S1: Preparation of Chin Fiber:

[0052] S2: 40 parts of the beete fiber in mass, 90 parts of natural color cotton fiber, and the diameter of each raw material fiber is not more than 60 um.

[0053] S3: 35 parts by weight of the weight, 30 parts of the antistatic agent and 40 parts of the antibacterial solution are added to the deionized water, resulting in a solution, and then adding the chip fibers and natural cotton fibers to the solution while carrying out Ultrasonic oscillating treatment, standing for 30 mi n, removing dehydration drying.

[0054] S4: combed with a strip to make a fibrous strip with a sage fiber and a natural color cotton fiber.

[0055] S5: The fiber strip is drawn and twisted by a roving machine to make a roving, the coarse spinning machine pressure rod adjustment ring i...

Embodiment 3

[0068] like figure 1 As shown, a method of preparing a chitin natural color cotton mixed yarn in accordance with an embodiment of the present invention includes the following steps:

[0069] S1: Preparation of Chin Fiber:

[0070] S2: Take 25 parts of the beete fiber in weight parts and 75 parts of natural colorless cotton fiber, and each raw material fiber is not more than 60 um.

[0071] S3: 30 parts by weight of the weight, 28 parts of the antistatic agent and 35 parts of the antibacterial solution are added to the deionized water, resulting in a solution, then the chipper fibers and natural cotton fibers are added to the solution, while performing Ultrasonic oscillating treatment, standing for 30 mi n, removing dehydration drying.

[0072] S4: combed with a strip to make a fibrous strip with a sage fiber and a natural color cotton fiber.

[0073] S5: The fibrous strip is drawn and twisted by the roving machine, and the coarse spinning machine pressure rod regulating the ring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com