A solid-liquid separation system for aquaculture wastewater ammonia nitrogen treatment system

A treatment system, solid-liquid separation technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of easy sticking of granular waste, poor effect of pore filtration of wastewater, and pore blockage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

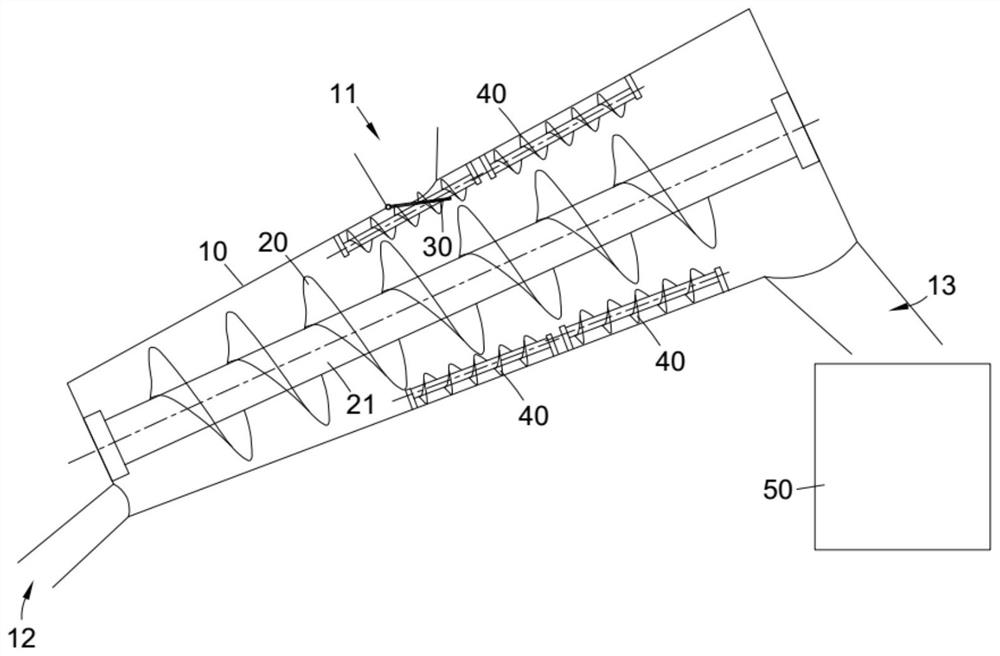

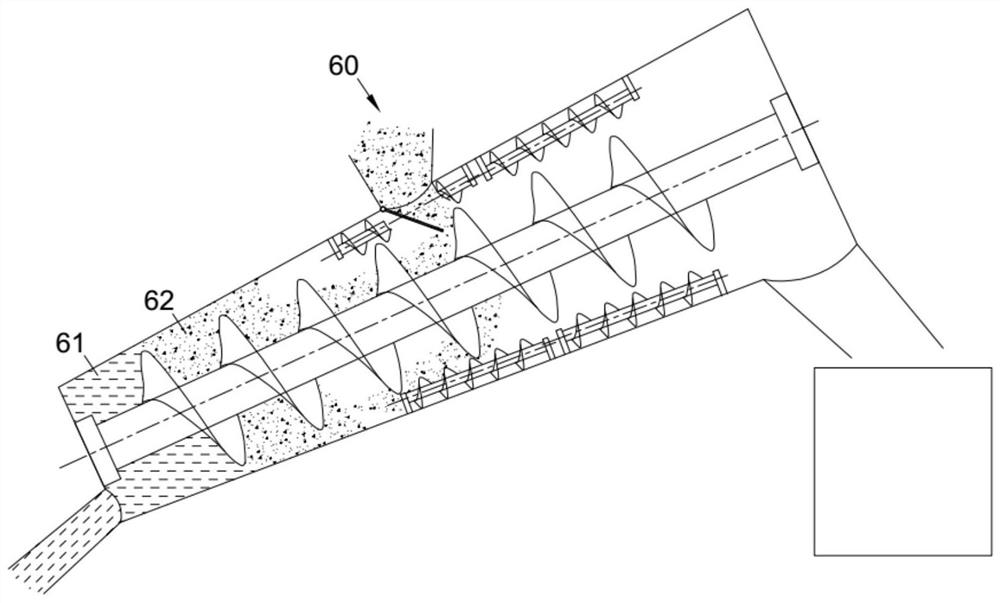

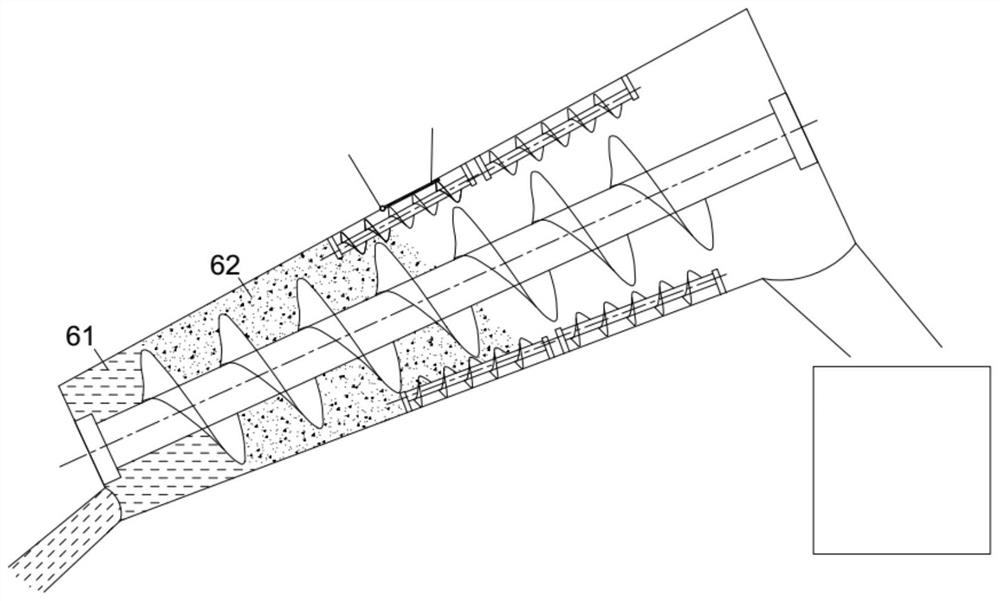

[0020] like figure 1 , a solid-liquid separation system of aquaculture wastewater ammonia nitrogen treatment system, including a cylinder 10 and an auger 20 arranged in the cylinder, the cylinder is fixedly arranged, the cylinder is inclined, the shaft 21 where the auger is located is connected to the motor, and the cylinder is From the bottom to the top, the inner diameter gradually increases. The feed port 11 on the cylinder is set above the bottom of the auger, the water outlet 12 on the cylinder is set below the bottom of the auger, and the outlet 13 on the cylinder is located at the bottom of the auger. Set at the top of the auger.

[0021] According to the patent document of Application Publication No. CN 111977902 A, due to the existence of the blades 302 , the waste water and waste enter the opening 401 of the drum 4 in a batch-by-batch manner. The present invention is a substitute for the solid-liquid separation system in the patent document of application publicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com