Glass crusher

A crusher and glass technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of the personal safety of the staff, affect the filtration of glass debris, and the crushing roller can not be broken effectively, so as to achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

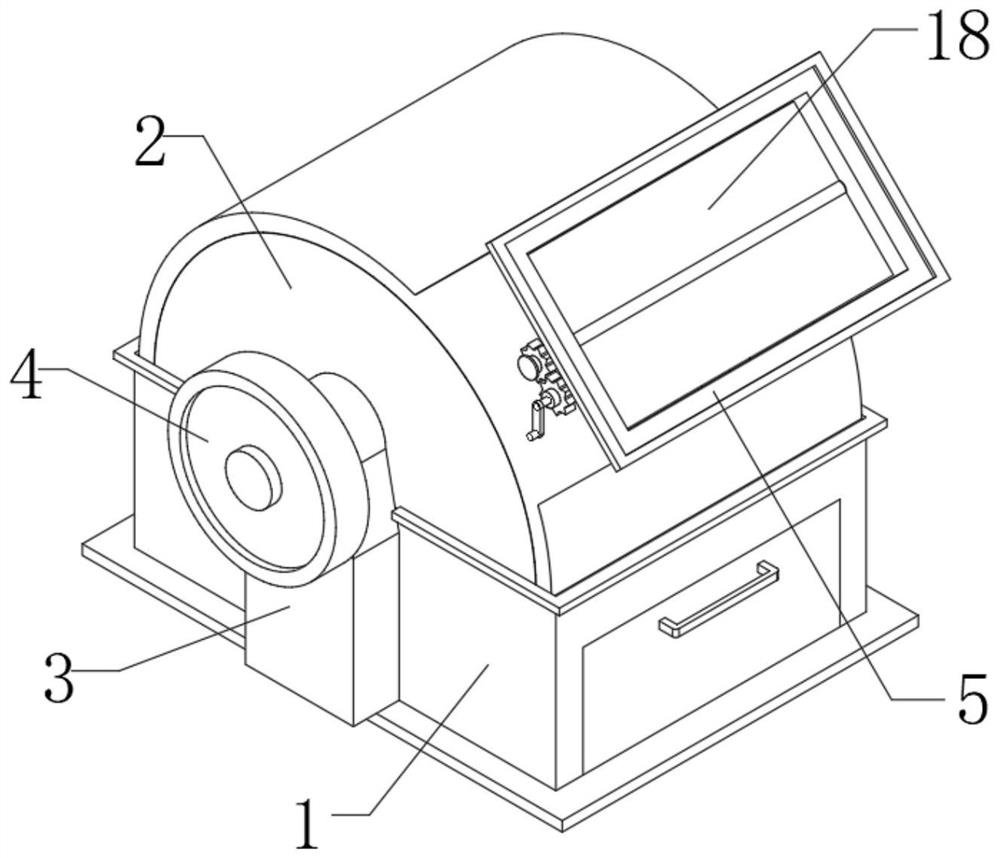

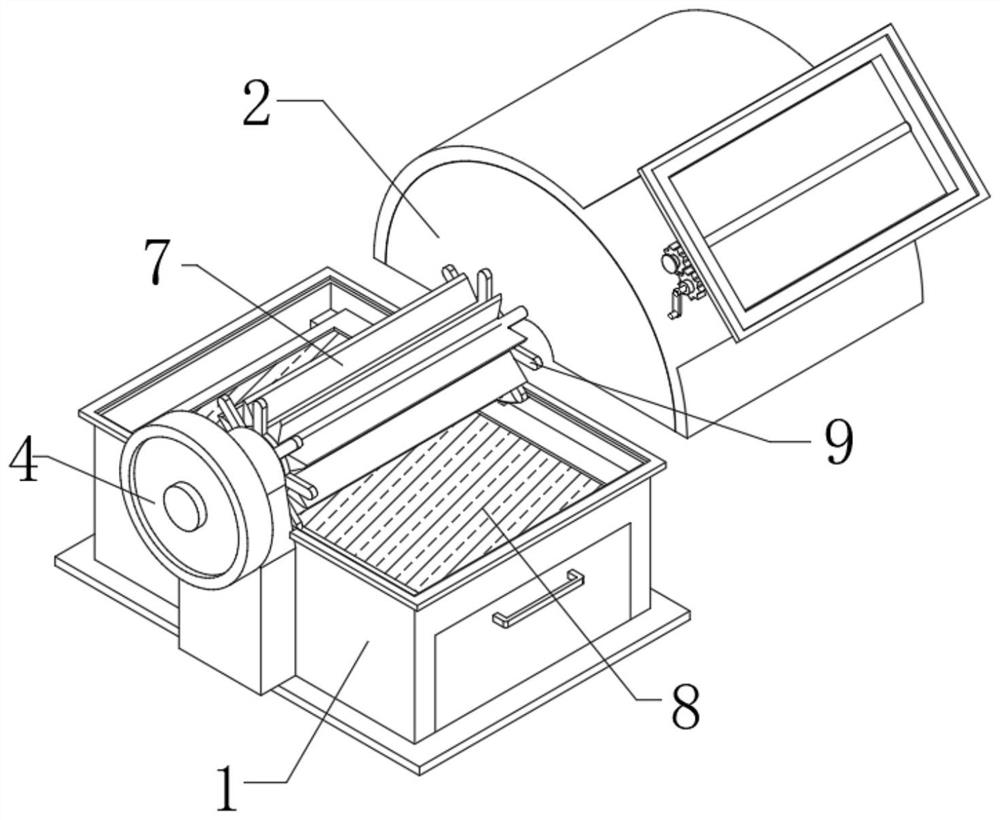

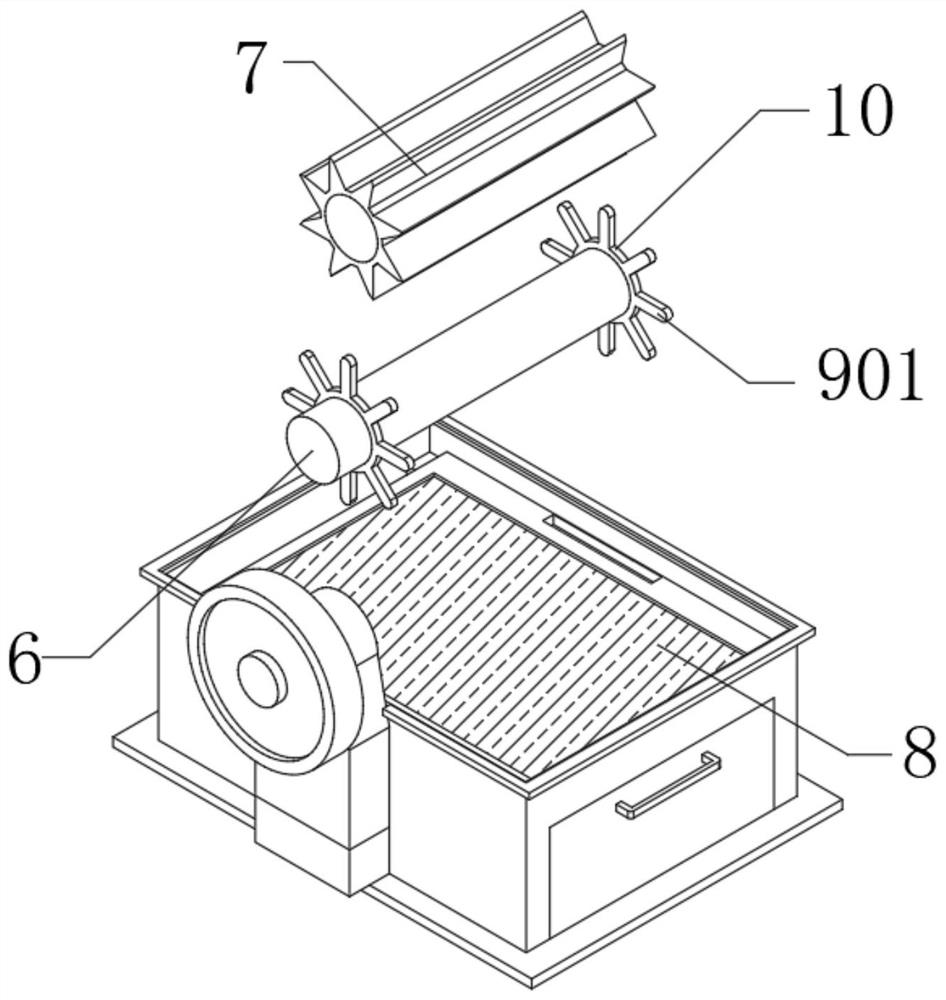

[0042] Such as Figure 1-9 The shown glass crusher includes a crusher main body 1, the upper surface of the crusher main body 1 is equipped with a casing 2, one side of the crusher main body 1 is fixedly installed with a fixed seat 3, and one side of the fixed seat 3 is rotatably connected with a The connecting column 6 is equipped with a motor 4 on one side of the connecting column 6, and the outer surface of the connecting column 6 is fixedly sleeved with a crushing roller 7, and the outer surface of the casing 2 is provided with a feed port 5, and the inside of the feed port 5 is equipped with a baffle 18;

[0043] The shaking mechanism 9 is installed inside the main body 1 of the crusher. The shaking mechanism 9 includes a push plate 901. Multiple groups of push plates 901 are assembled on the outer surface of the connecting column 6. The inside of the main body 1 of the crusher is equipped with a filter plate 8. One end of multiple sets of push plates 901 is rotatably co...

Embodiment 2

[0047] Such as Figure 1-9 A glass breaker is shown, based on the description in Embodiment 1, one side of the feed port 5 is rotatably connected with a fixed rod 19, and a connecting hole 20 is opened inside the baffle plate 18, and the baffle plate 18 is fixed through the connecting hole 20. Be connected to the outer surface of fixed rod 19, one side of feeding port 5 is equipped with rotating mechanism 21, and rotating device 21 comprises first gear 211, threaded rod 212 and second gear 213, and fixed rod 19 extends out of feeding port 5 The outer surface of one end is fixedly sleeved with a first gear 211, one side of the case 2 is rotatably connected with a threaded rod 212, the threaded rod 212 is located on one side of the fixed rod 19, and the outer surface of the threaded rod 212 is fixedly sleeved with a second gear 213 , the first gear 211 and the second gear 213 are meshed, and a handle 22 is fixedly installed on one side of the threaded rod 212 .

[0048] First, ...

Embodiment 3

[0051] Such as Figure 1-9 Shown is a glass crusher, based on the description in Embodiments 1 and 2, the side wall of the crusher main body 1 is fixedly equipped with a bearing plate 13, and the filter plate 8 is slidably connected to the upper surface of the bearing plate 13, and the length of the filter plate 8 is Less than the length of the bearing plate 13, the length of the bearing plate 13 is equal to the length of the main body 1 of the crusher, and the lower surface of the two sets of bearing plates 13 is slidingly connected with the collection box 11, the collection box 11 is located directly below the filter plate 8, the collection box 11 The two sides of the crusher are equipped with spherical rods, and the spherical rods are movably clamped in the inside of the main body 1 of the crusher.

[0052] The collection box 11 slides to the inside of the crusher main body 1 through the hole on one side of the crusher main body 1, and is located directly below the filter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com