Reinforcing mesh assembling device and reinforcing mesh cage assembling method

An assembly method and networking technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of reducing the production efficiency of autoclaved aerated concrete panels, reducing the networking efficiency, etc., to improve the connection efficiency, improve the The effect of networking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

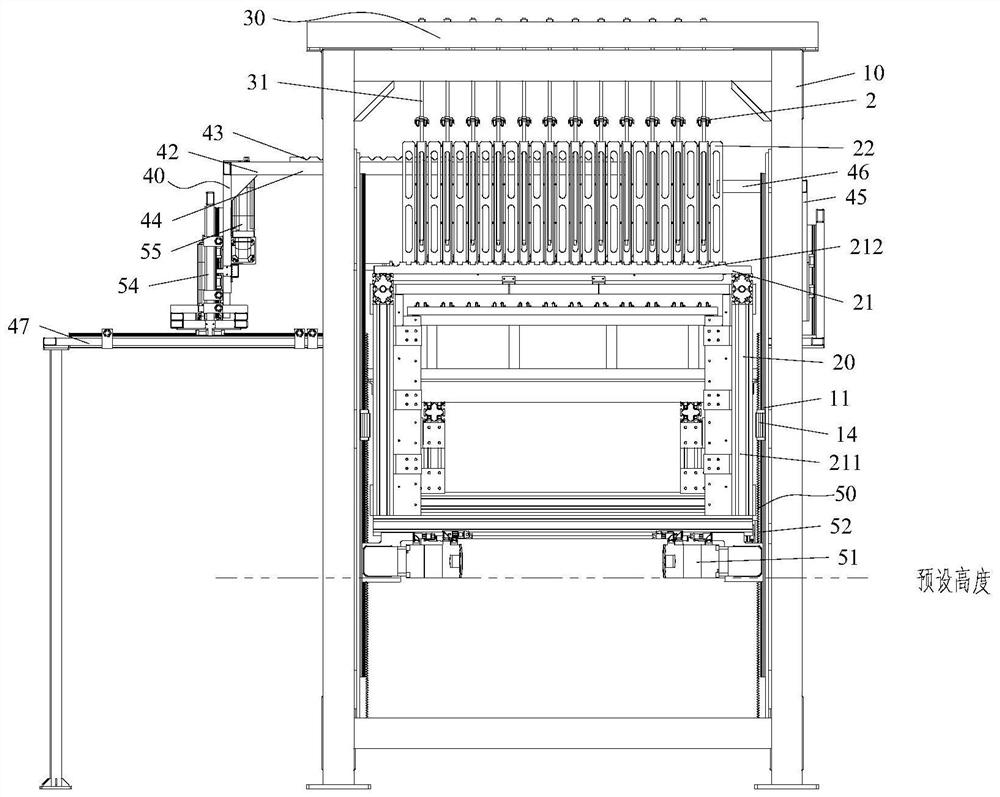

[0042] Such as figure 1 As shown, Embodiment 1 of the present invention provides a networking device. The networking device is used for assembling the mesh 1 and the buckle structure 2 , and the networking device includes a mesh lifting mechanism 50 , a mesh supporting structure 20 and a first cantilever structure 40 . Wherein, the mesh supporting structure 20 is arranged on the mesh lifting mechanism 50, and the mesh supporting structure 20 is used to accommodate a plurality of meshes 1 arranged in sequence; at least part of the mesh lifting mechanism 50 is movably arranged in the vertical direction, so as to Drive the mesh support structure 20 and the mesh 1 on the mesh support structure 20 to move synchronously, the first cantilever structure 40 is located on one side of the mesh lifting mechanism 50, the first cantilever structure 40 includes the first cantilever part 42, the first cantilever structure 40 The cantilever portion 42 is movably arranged in the vertical direc...

Embodiment 2

[0108] The difference from Example 1 is that, if Figure 10 As shown, in the second embodiment of the present invention, the first cantilever structure 40 includes two first cantilever portions 42 with a preset distance. Likewise, the second cantilever structure 45 includes two second cantilever portions 46 with a preset distance, and the second cantilever portions 46 are used to support the first cantilever portion 42 to prevent deformation of the first cantilever portion 42 to ensure better The longitudinal ribs of the ground support mesh.

[0109] It should be noted that the setting of the preset distance needs to ensure that the two first cantilever portions 42 can simultaneously correspond to the outermost longitudinal ribs (ie, the uppermost longitudinal ribs and the lowermost longitudinal ribs) of the supporting mesh. For example, the preset distance can be set to be equal to the vertical distance between the outermost longitudinal ribs of the mesh. In this way, by pro...

Embodiment 3

[0112] The difference from Example 1 is that, if Figure 11 As shown, the networking device includes two first cantilever structures 40 and two second cantilever structures 45 corresponding to the two first cantilever structures 40, and the two first cantilever structures 40 can be separated from each other to separate the mesh The uppermost longitudinal reinforcement and the lowermost longitudinal reinforcement are used for support.

[0113] In this way, two second drive structures 55 also need to be provided, so that the two first cantilever structures 40 can be driven away from each other, so that the mesh can be snapped into the upper buckle structure and the lower buckle structure respectively. , to complete the automatic networking process.

[0114] Other structures in the third embodiment are the same as those in the first embodiment, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap