Liquid cooling pump cavity flow channel structure and liquid cooling pump

A pump cavity and liquid cooling technology, applied in the field of liquid pumps, can solve the problems of limited application occasions, high energy consumption, large size, etc., and achieve the effects of favorable flow rate, improved work efficiency, and good diversion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

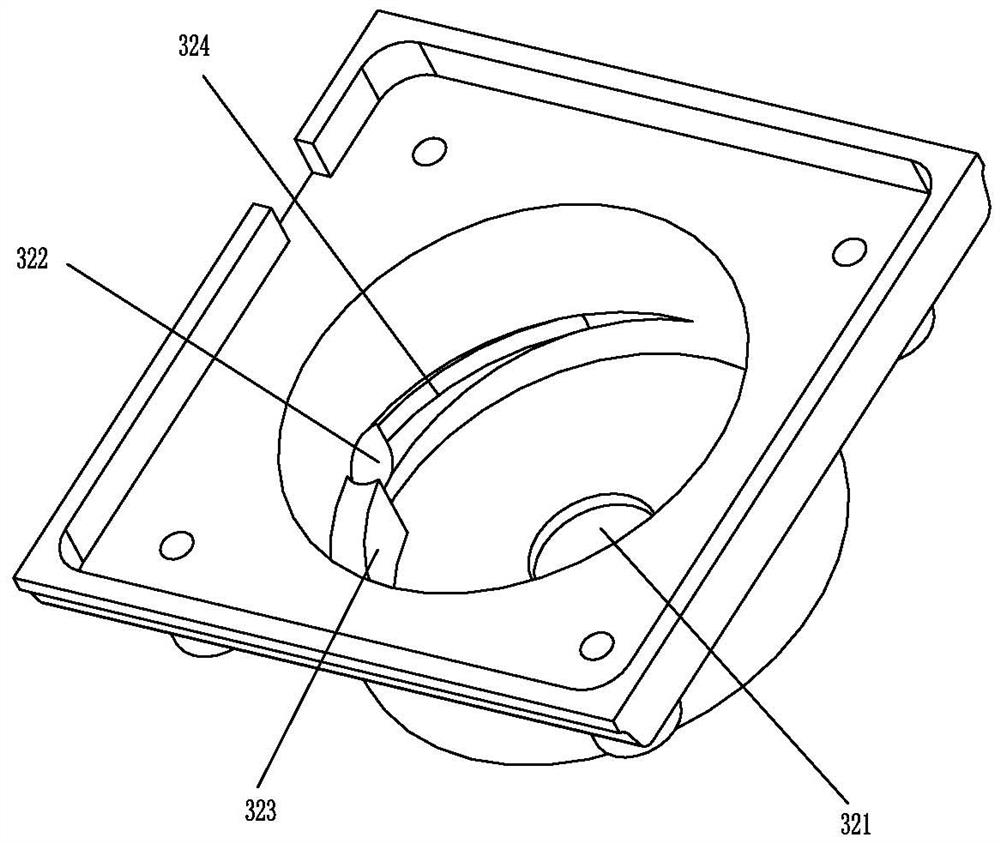

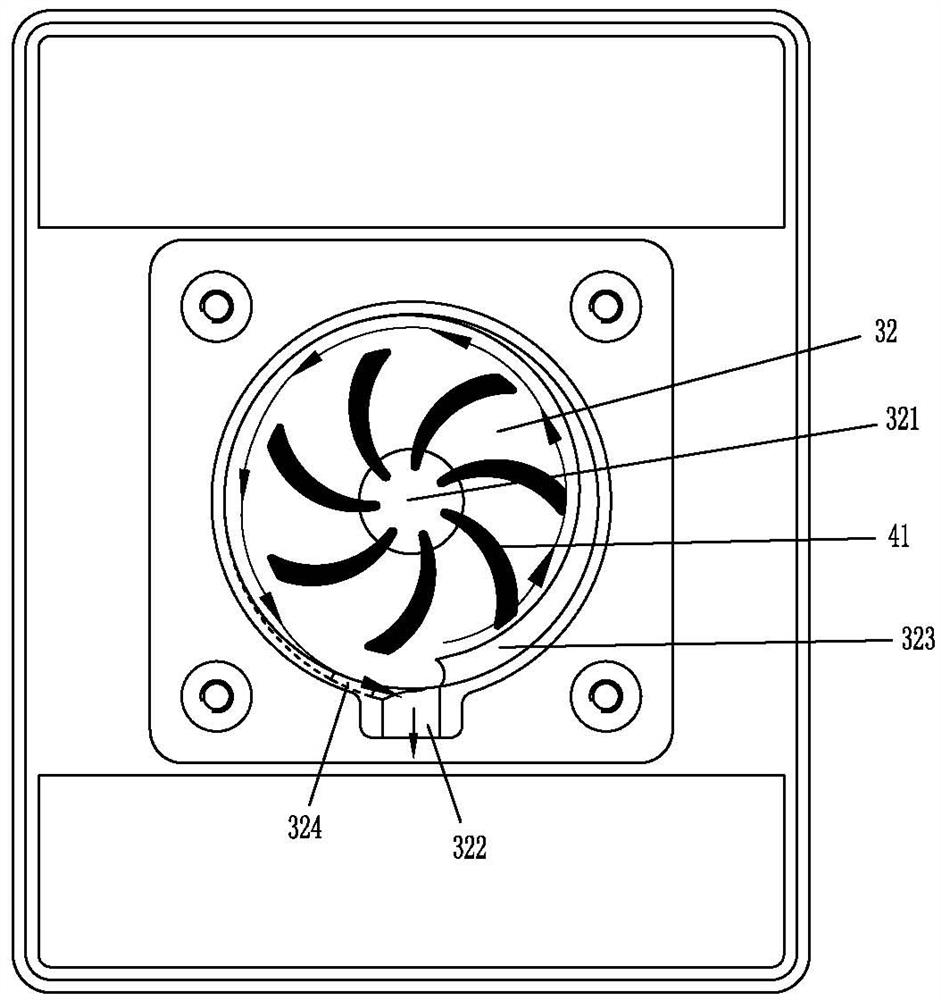

[0032] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention. .

[0033] A liquid-cooled pump chamber flow channel structure, including a liquid pump installation cavity 32, the bottom of the liquid pump installation cavity 32 is provided with a liquid inlet hole 321 in the center, and the circumferential side of the liquid pump installation cavity 32 is provided with a liquid outlet hole 322; on the side wall of the inner peripheral side wall of the liquid pump installation chamber 32 corresponding to the liquid outlet hole 322, a liquid blocking boss 323 is protruded, and the other side corresponding to the liquid outlet hole 322 is concavely provided with a guide groove 324; The rotation axis of the impeller 41 of the liquid pump is the front-rear direction, the liquid blocking boss 323 is arranged in a gradually thinning manner along the rotation circumference of the impeller 41, and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com