Improved shear wall formwork reinforcing method

A formwork reinforcement and shear wall technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the inconvenience of shear wall formwork reinforcement. , Unfavorable recycling of turnover materials, affecting the quality of concrete molding, etc., to achieve the effect of reducing screw holes through the wall, quality assurance, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

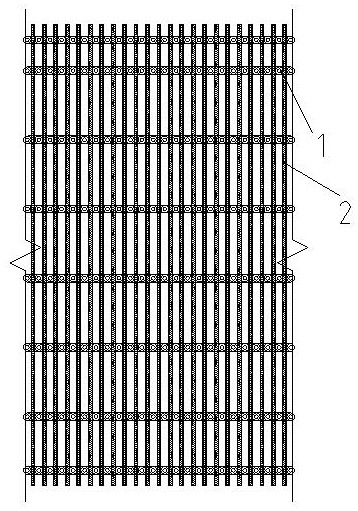

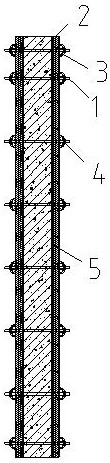

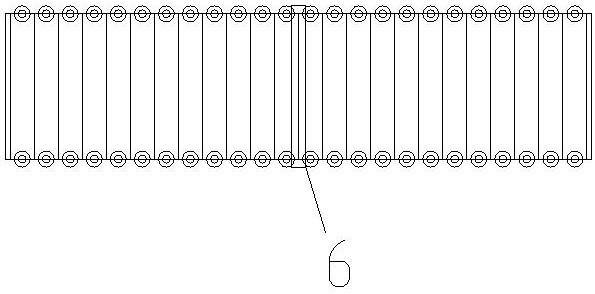

[0028] see now Figure 1-3 , the improved shear wall formwork reinforcement method of the present invention, its reinforcement system is mainly made up of laminated wood plywood panel 5, steel pipe secondary corrugation 2, steel pipe main corrugation 3, pull screw 1, and seam beam 6.

[0029] Specifications of materials used:

[0030] 1) Laminated wood plywood panel: length × width = 1830mm × 900mm, panel thickness 15mm.

[0031] 2) Steel pipe secondary flute, steel pipe main flute: diameter x wall thickness = 48mm x 3.0mm, length 6m.

[0032] 3) Pulling screw: the diameter is not less than 16mm, and it is fastened with a mountain-shaped butterfly buckle 4.

[0033] 4) Patchwork wooden frame: thickness×width=40mm×90mm, length 3000mm.

[0034] The specific operation of the improved shear wall formwork reinforcement method of the present invention: the reinforcement method is applicable to a shear wall height not greater than 6m, and a shear wall thickness not greater than 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com