Drum washing machine

A technology of a drum washing machine and an inner drum, which is applied in the field of washing machines, can solve the problems of small water pressure driving force, etc., and achieve the effects of satisfying the spraying requirements and various water flow disturbance effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

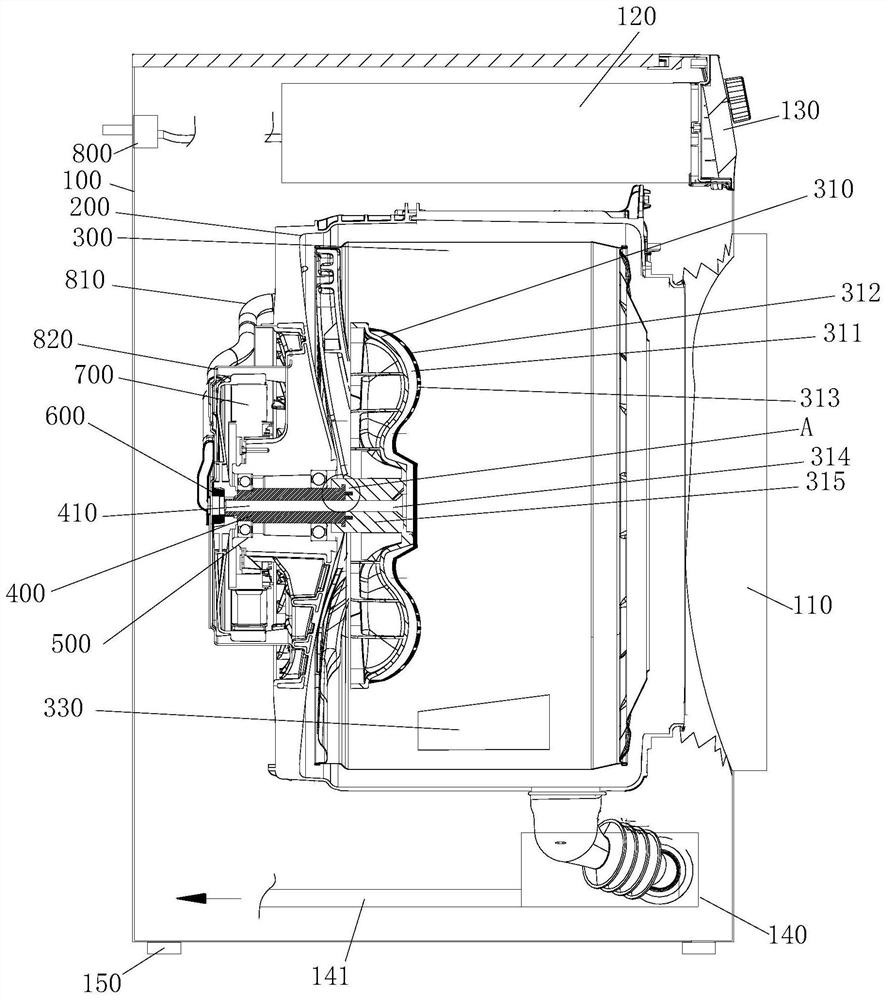

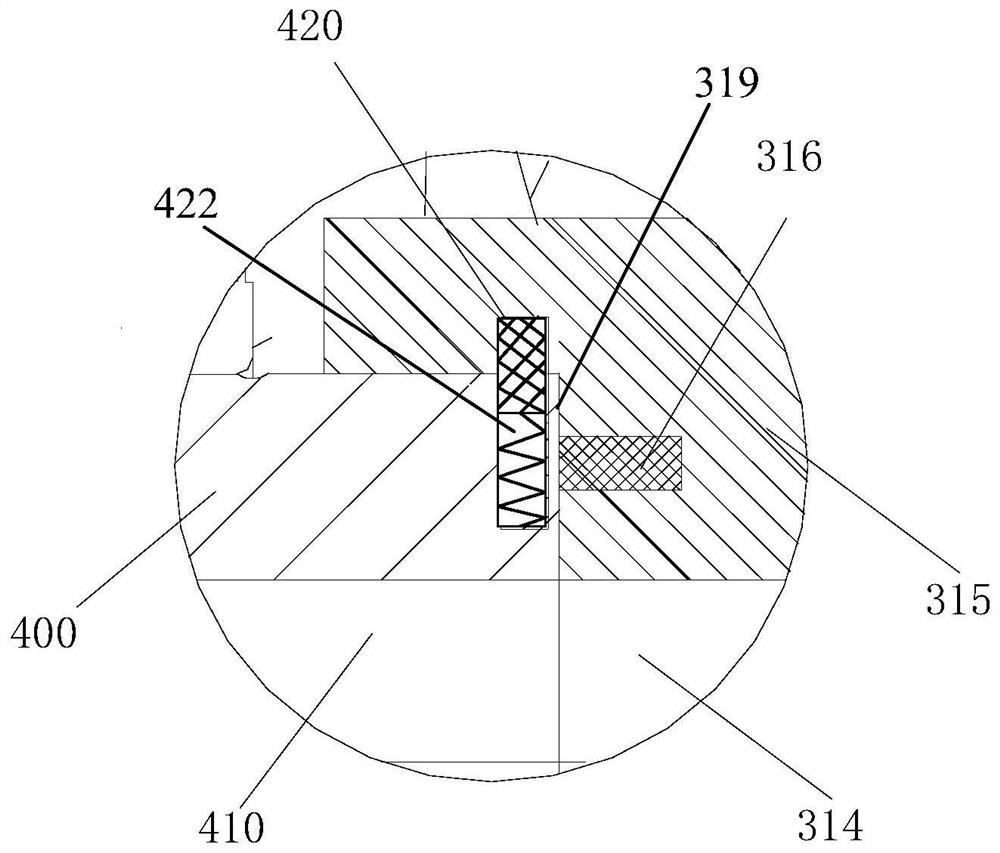

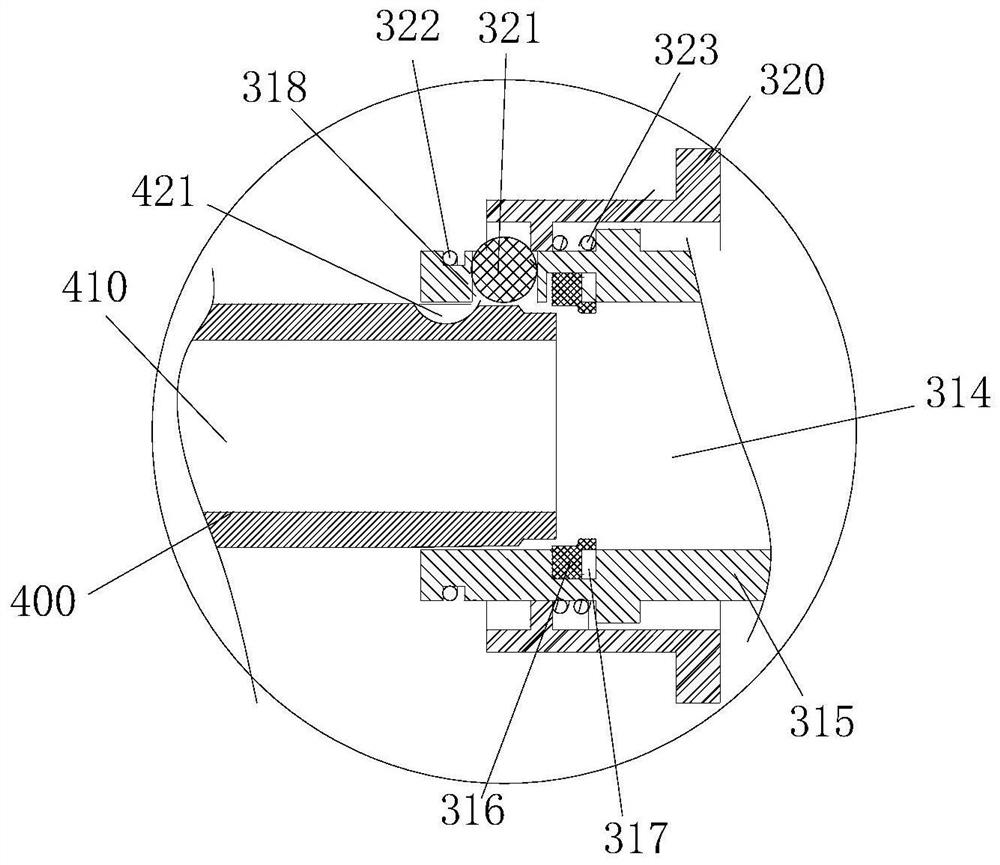

[0048] Such as figure 1 As shown, a drum washing machine includes a body 100, an outer cylinder 200 and an inner cylinder 300 arranged in the body 100, and the outer cylinder 200 and the inner cylinder 300 are arranged coaxially. The outer cylinder 200 is fixed inside the machine body 100 , and the inner cylinder 300 is fixed on the drive shaft 400 and driven to rotate by the drive shaft 400 . Lifting ribs 330 are provided in the inner tube 300, which can lift the clothes in the inner tube 300 to a certain height, and then the clothes will fall down. After continuous lifting-dropping, the effect of beating is played, so as to achieve the cleaning effect on the clothes. In order to enhance the wetting effect of the clothes in the inner cylinder 300, a spraying and stirring device is also provided in the present invention, and the water is sprayed in the inner cylinder 300 through the spraying and stirring device, which can effectively improve the wetting effect of the clothes. ...

Embodiment 2

[0060] Such as figure 1 As shown, a drum washing machine includes a body 100, an outer cylinder 200 and an inner cylinder 300 arranged in the body 100, and the outer cylinder 200 and the inner cylinder 300 are arranged coaxially. The outer cylinder 200 is fixed inside the machine body 100 , and the inner cylinder 300 is fixed on the drive shaft 400 and driven to rotate by the drive shaft 400 . Lifting ribs 330 are provided in the inner tube 300, which can lift the clothes in the inner tube 300 to a certain height, and then the clothes will fall down. After continuous lifting-dropping, the effect of beating is played, so as to achieve the cleaning effect on the clothes. In order to enhance the wetting effect of the clothes in the inner cylinder 300, a spraying and stirring device is also provided in the present invention, and the water is sprayed in the inner cylinder 300 through the spraying and stirring device, which can effectively improve the wetting effect of the clothes. ...

Embodiment 3

[0072] Such as figure 1As shown, a drum washing machine includes a body 100, an outer cylinder 200 and an inner cylinder 300 arranged in the body 100, and the outer cylinder 200 and the inner cylinder 300 are arranged coaxially. The outer cylinder 200 is fixed inside the machine body 100 , and the inner cylinder 300 is fixed on the drive shaft 400 and driven to rotate by the drive shaft 400 . Lifting ribs 330 are provided in the inner tube 300, which can lift the clothes in the inner tube 300 to a certain height, and then the clothes will fall down. After continuous lifting-dropping, the effect of beating is played, so as to achieve the cleaning effect on the clothes. In order to enhance the wetting effect of the clothes in the inner cylinder 300, a spraying and stirring device is also provided in the present invention, and the water is sprayed in the inner cylinder 300 through the spraying and stirring device, which can effectively improve the wetting effect of the clothes. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com