Diamond cutting method and diamond

A cutting method and diamond technology, applied in the field of diamonds, can solve the problem of no major morphological breakthrough, and achieve the effects of increasing fire color, increasing the number of refractions, and increasing the value of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] In a further embodiment of the present invention, the diamond cutting method includes:

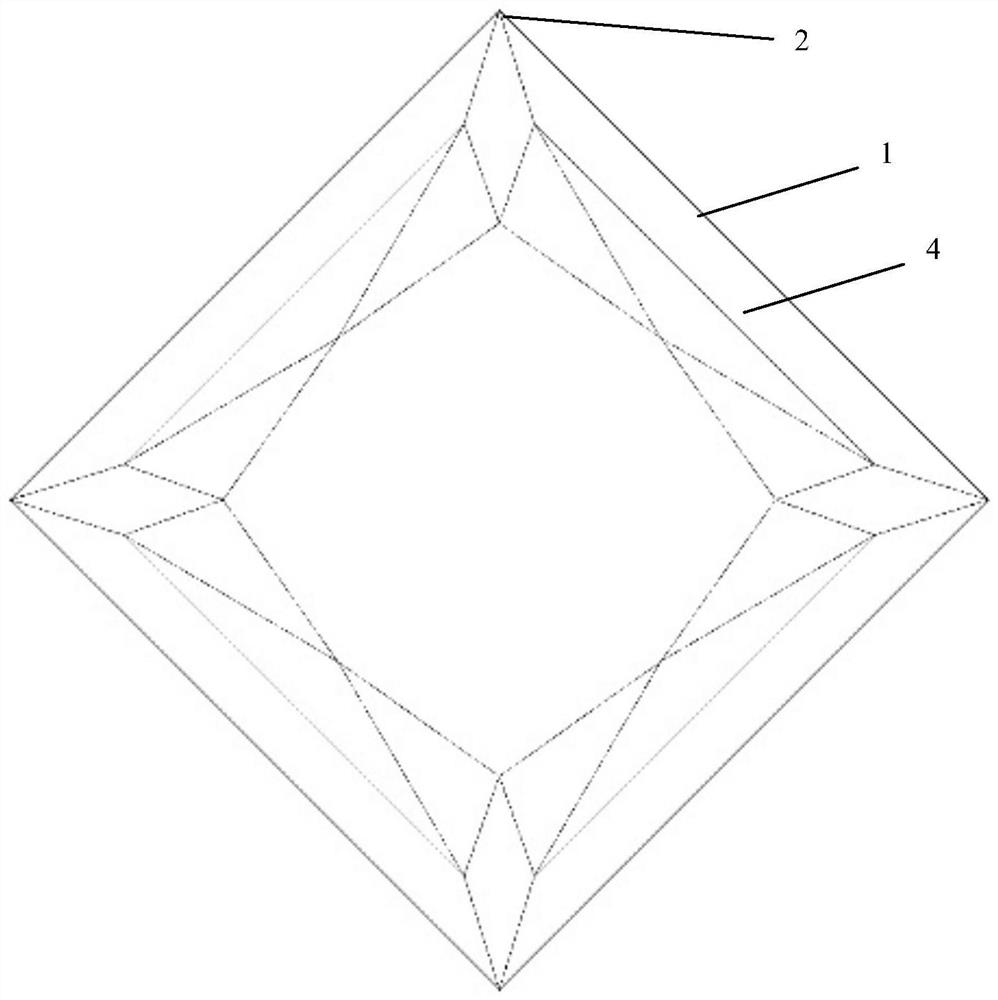

[0052] S1: Provide a rectangular-cut diamond to be processed, the girdle of the diamond to be processed has four interconnected and rectangular long sides 1, and a corner 2 is defined between each two adjacent long sides 1;

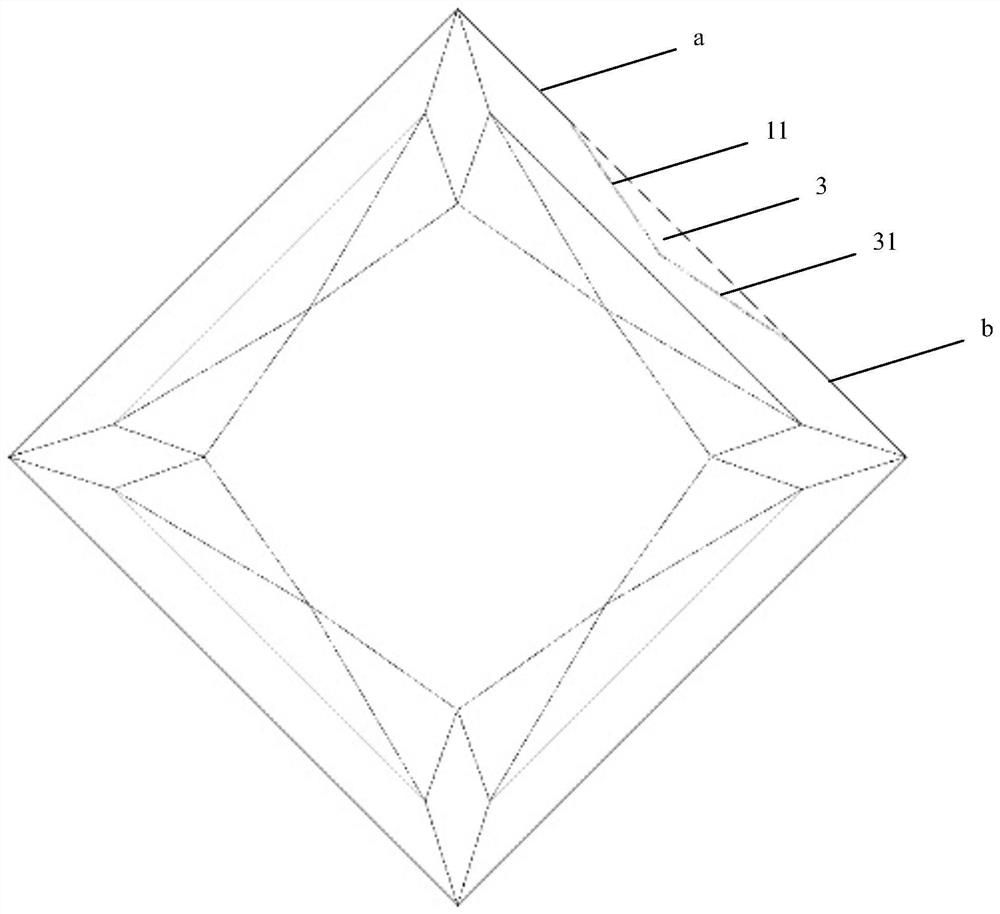

[0053] S2: Select a long side surface 1, rough cut this long side surface 1, and remove part of the material of the diamond to be processed close to the long side surface 1 from the direction of the long side surface 1 to the center of the diamond to be processed, so as to be in the original length A rough-cut waist surface 11 is formed near the position of the side surface, wherein the two ends of the rough-cut waist surface 11 have a first distance a and a second distance b between the corners 2 of the two ends of the long side surface 1;

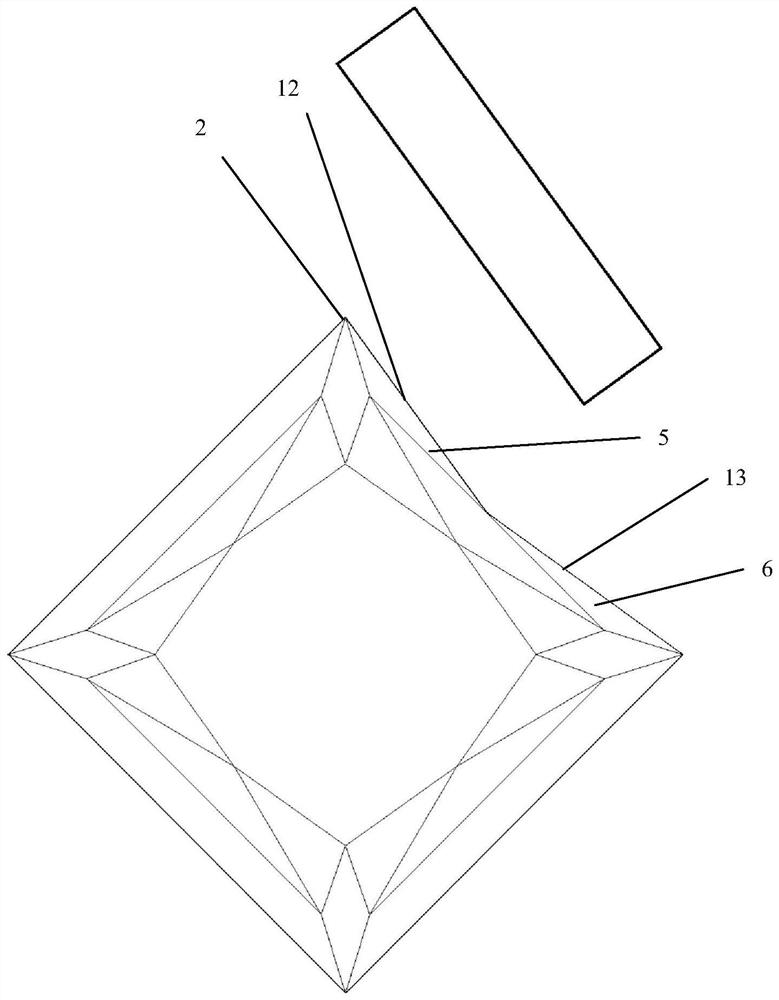

[0054] S3: finish cutting and trimming the rough-cut girdle 11, so that the rough-cut girdle 11 forms a first girdle 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com