Safe dust treatment equipment

A technology for safe treatment and equipment, applied in the field of workshop safety, can solve problems such as insufficient utilization of circulating water, easy blockage of filter screens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

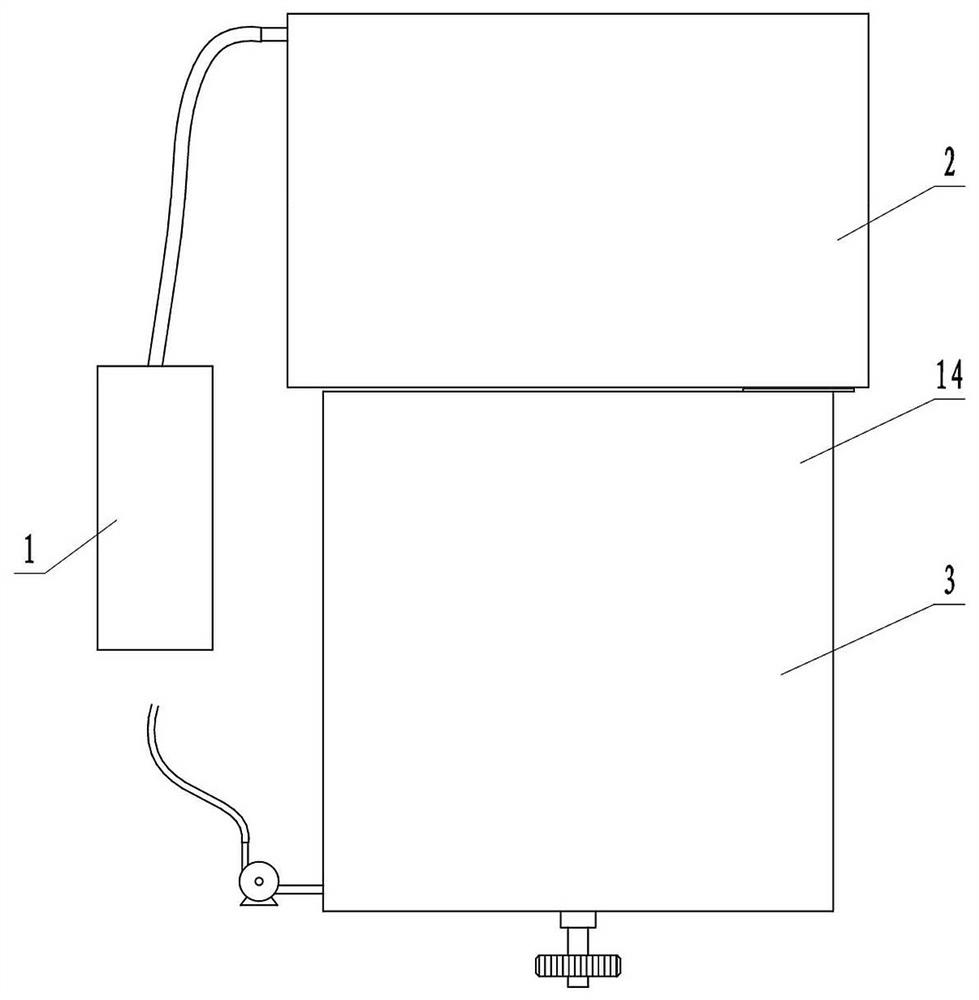

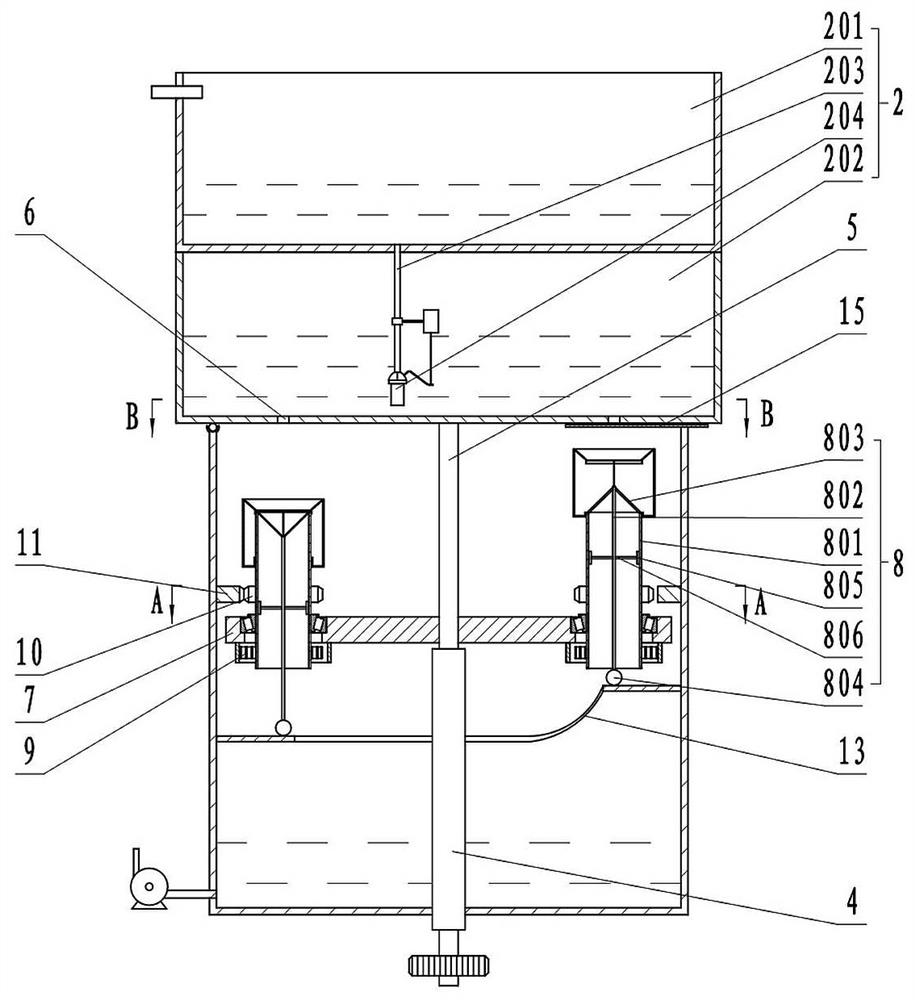

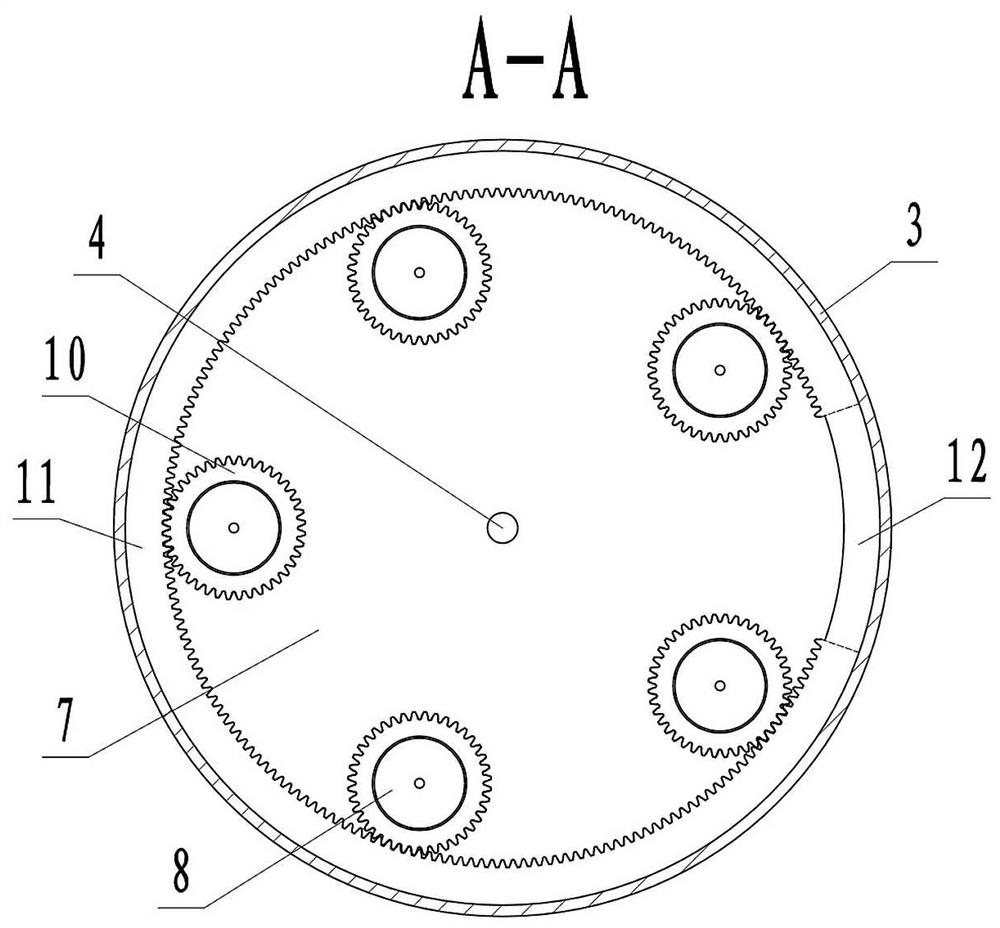

[0019] Depend on Figure 1 to Figure 5 Given, the present invention includes a dust washer 1 and a water tank, the water tank and the vacuum cleaner are connected through a circulation pump, the water tank includes an upper box 2 and a lower box 3, the lower box 3 is fixed, and the middle part of the lower box 3 is fixedly installed with Vertical sleeve 4, sleeve 4 runs through the bottom of lower box body 3, rotating shaft 5 is installed in the sleeve 4, the upper end of rotating shaft 5 is fixed with the bottom of upper box body 2; The bottom circumference of upper box body 2 is provided with A plurality of drain holes 6; the rotating shaft 5 is fixedly mounted with a turntable 7 located below the lower box body 3, and a plurality of filters 8 corresponding to the drain holes 6 are installed on the turntable 7, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com