Novel permanent magnet synchronous motor stator structure with high thermal conductivity and low pulsation

A permanent magnet synchronous motor and stator structure technology, which is applied in the magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc. Difficulty in heat conduction and other problems, to achieve the effect of improving thermal conductivity, reducing the distortion rate of air gap magnetic density, and increasing the number of slots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

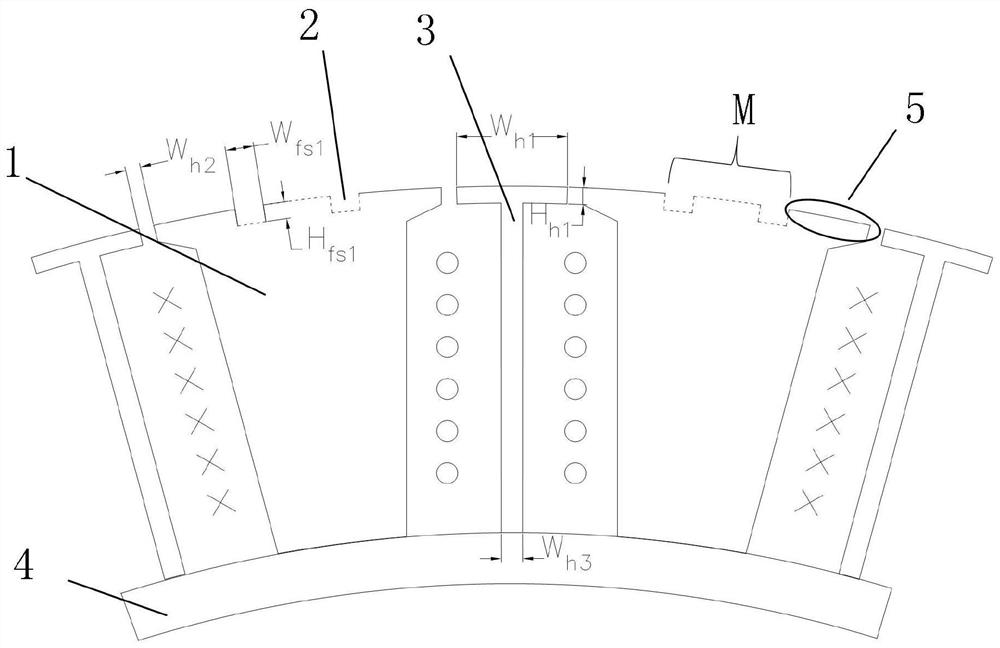

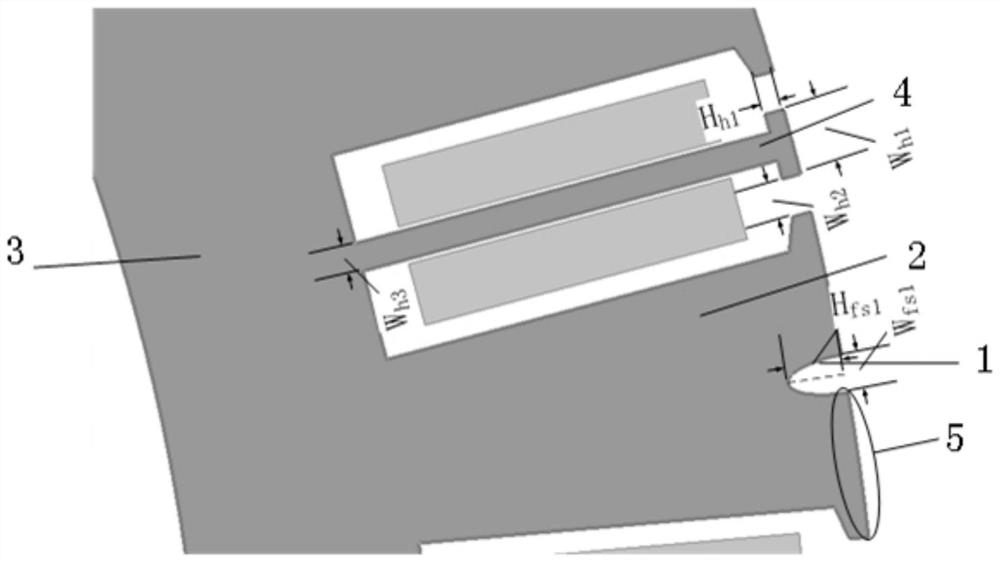

[0042] see figure 1 and figure 2 , a new type of permanent magnet synchronous motor stator structure with high thermal conductivity and low pulsation. The stator is composed of two parts: stator core and concentrated winding. The stator core includes open stator teeth 1 and stator yoke 4; the stator winding is a fraction with a span of 1 Slot concentrated winding; M auxiliary slots 2 are opened on the tooth crown of each stator tooth 1; a heat conducting rod 3 with good thermal conductivity is inserted into each stator slot.

[0043] The new permanent magnet synchronous motor stator structure with high thermal conductivity and low pulsation in this embodiment can not only weaken the tooth harmonics, reduce torque ripple and vibration noise, improve torque quality, but also reduce the temperature rise of the motor and improve the thermal conductivity of the motor. This increases the power / torque density of the motor.

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0046]The auxiliary slots 2 on the crown of the stator tooth 1 are as follows: taking the neutral line of the stator tooth 1 as the reference, the auxiliary slots 2 are evenly distributed on the stator crown, and the number M of auxiliary slots 2 on each stator tooth 1 should satisfy M+2≠tN p , t is any positive integer, p is the number of pole pairs, Q is the number of slots; the shape of the auxiliary slot is a rectangular slot, or a pear-shaped slot, or a half-pear-shaped slot, or a circular slot; after the auxiliary slot 2 is opened, each stator tooth 1 forms M+1 A small tooth crown 5.

[0047] The inserted heat conducting rod 3 is:

[0048] (a) The heat conduction rod 3 is made of high thermal conductivity material;

[0049] (b) Its bottom end is to be connected with the stator yoke 4;

[0050] (c) The top, that is, the surface of each heat conducting rod 3 shoul...

Embodiment 3

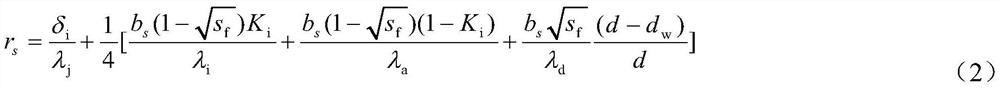

[0055] This example is a 36-slot 48-pole motor that adopts the new permanent magnet synchronous motor stator structure with high thermal conductivity and low pulsation of the present invention, see figure 2 , its stator features and its implementation steps are:

[0056] (1) Determine the stator structure: the stator is composed of two parts: the stator core and the concentrated winding. The stator core includes the stator teeth 1 with the auxiliary slot 2, the stator yoke 4 and the heat conduction rod 3. It is characterized in that:

[0057] (a) The winding method of the stator winding is a fractional slot concentrated winding with a span of 1;

[0058] (b) M auxiliary slots 2 are opened on each stator tooth 1;

[0059] (c) A thermally conductive rod 3 with good thermal conductivity is inserted into each stator slot.

[0060] (2) Open auxiliary slot 2 on each stator tooth 1:

[0061] (a) Determine the number M of auxiliary slots: its cogging torque N p =4>1, M should sat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com