Fireproof and explosion-proof new energy automobile storage battery structure

A technology for new energy vehicles and batteries, applied in secondary batteries, structural parts, battery covers/end covers, etc., can solve problems affecting users' life and property safety, potential safety hazards, battery fires, etc., to reduce the chemical reaction rate, The effect of preventing fire and explosion, and preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

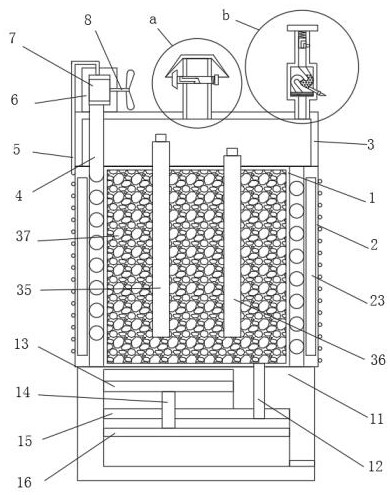

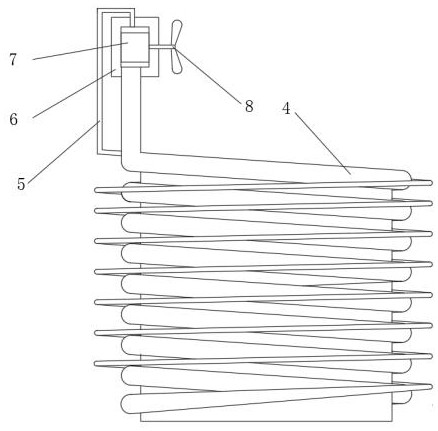

[0024] Embodiment 1: as figure 2 and Figure 6 As shown, when the new energy electric vehicle is running on the road, the fan blades are blown by the wind and start to rotate, the cooling liquid in the cooling pipe 5 is blown and cooled by the outside wind, and the right end of the first rotating shaft 8 is welded with 3-6 fan blades. blade, the blade rotates to rotate the first shaft 8, the first shaft 8 rotates the second gear 10 through the first gear 7, the first gear 7 meshes with the second gear 10, and the first gear 7 and the second gear 10 rotate through The cooling liquid in the cooling pipe 5 can be continuously pumped into the cooling pipe 4, so that the cooling liquid in the cooling pipe 4 absorbs the heat emitted by the battery and then flows into the cooling pipe 5 for air-cooling to cool down. The temperature is too high, resulting in damage to components and short circuits;

Embodiment 2

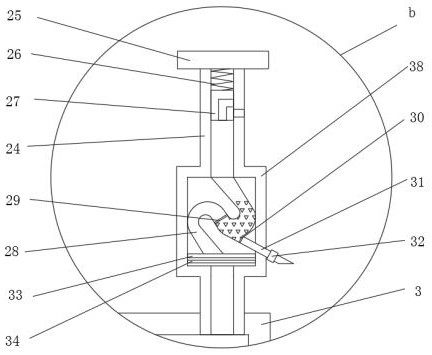

[0025] Embodiment 2: as figure 1 and Figure 5 As shown, when the gas in the protective cover 3 is affected by the heat of the battery, it will expand. The left side of the gas outlet pipe 17 is rotated and connected to the first column 19 that runs through and extends to the outside of the right side of the gas outlet pipe 17. The expanded gas continues to pass through the first column 19. The Z-shaped through hole of a cylinder 19 squeezes the first cylinder 19 to the left, and a Z-shaped vent hole is opened inside the first cylinder 19 until the expanded gas can pass through the Z-shaped through hole of the first cylinder 19 Discharge the protective cover 3 to prevent the positive pole 35 and negative pole 36 of the battery and the wires connected to them from being squeezed by high-pressure gas from being damaged and causing a short circuit. After the expanded high-temperature gas is discharged, the first spring 21 makes the first cylinder deform through elastic deformatio...

Embodiment 3

[0026] Embodiment 3: as figure 1 As shown, when the battery is overheated, the water in the second box 11 is heated and expands, and the top of the push rod 14 is welded with a first stopper 13, so that the first stopper 13 drives the piston 16 to move downward through the push rod 14 The top of the second box 11 is covered with an electrolyte tube 12 that runs through and extends to the bottom of the baffle 15, so that the electrolyte 37 in the battery flows into the sealed space formed by the piston 16 and the baffle 15 through the electrolyte tube 12, The chemical reaction rate in the battery is slowed down, and the overheated battery is prevented from being damaged and short-circuited to cause fire or explosion. After the battery cools down, the cooled and retracted water makes the piston 16 push the electrolyte 37 back into the battery case 1 through negative pressure. , to make the battery work normally;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com