Compressor assembly process

An assembly process and compressor technology, which is applied in the field of compressors, can solve the problems of reducing the assembly precision requirements of compressor products, increasing the operating noise of compressors, and affecting the batch production of compressors, so as to ensure smoothness and stability, reduce Compression leaks, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

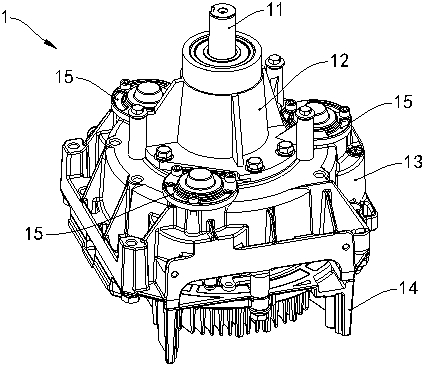

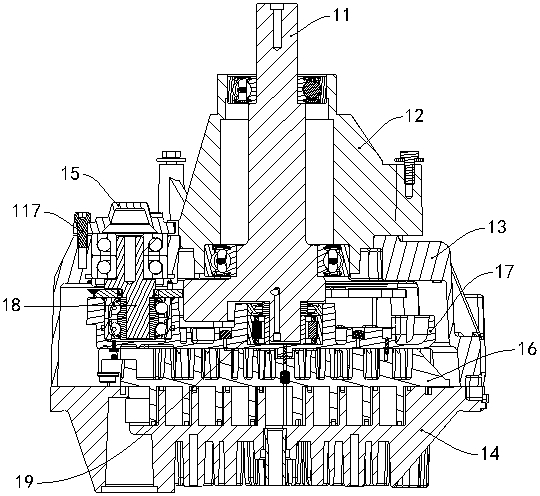

[0045] see figure 1 and figure 2 The compressor assembly 1 includes a crankshaft 11, a machine base 13, three eccentric pins 18, a fixed base 17, a moving disk 16 and a static disk 14, the crankshaft 11 is rotatably supported on the machine base 13, and the moving disk 16 is mounted on a fixed On the seat 17, and the fixed seat 17 is sleeved on the crankshaft 11. Wherein, three eccentric pins 18 are evenly distributed in the circumferential direction of crankshaft 11, and the first end of each eccentric pin 18 is rotatably supported on the base 13, and the second end of each eccentric pin 18 is rotatably supported on a fixed On the base 17, a pressure plate 15 is fastened on the machine base 13 by a screw 117 and covered on the first end of an eccentric pin 18. Moreover, the static disc 14 cooperates with the movable disc 16 and is fixedly installed on the base 13 .

[0046] The assembly process of the compressor in this embodiment includes the assembly steps of the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com