Rake head special for eliminating furrows and construction technology of rake head

A rake head and ditch technology, applied in the field of raking and suction boats, can solve the problems of increasing the cost of the ship, reducing the construction efficiency, and reducing the output of the ship, and achieves the effects of improving the ground breaking capacity, facilitating the ground breaking and reducing the ridges and ditch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

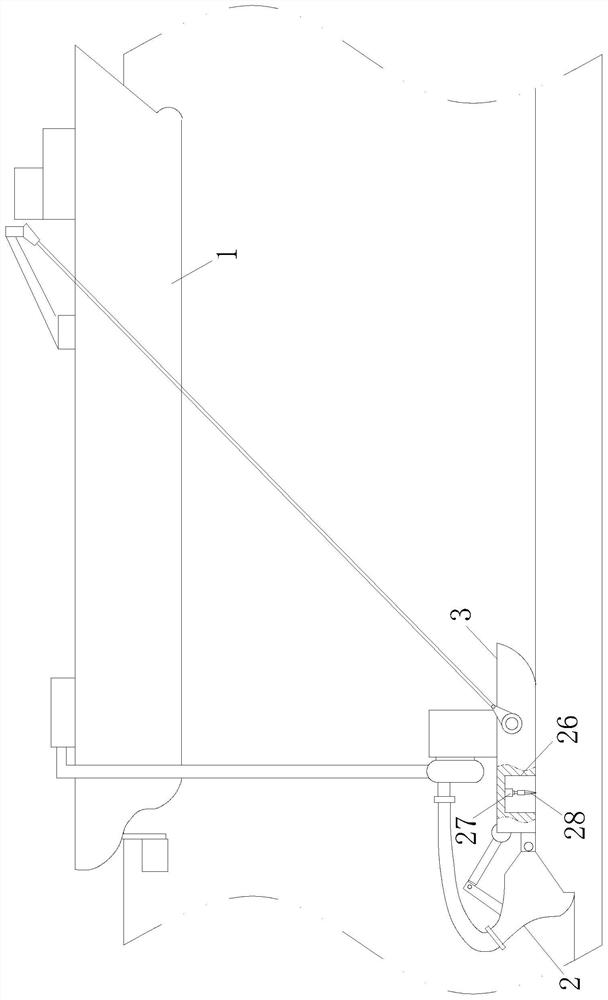

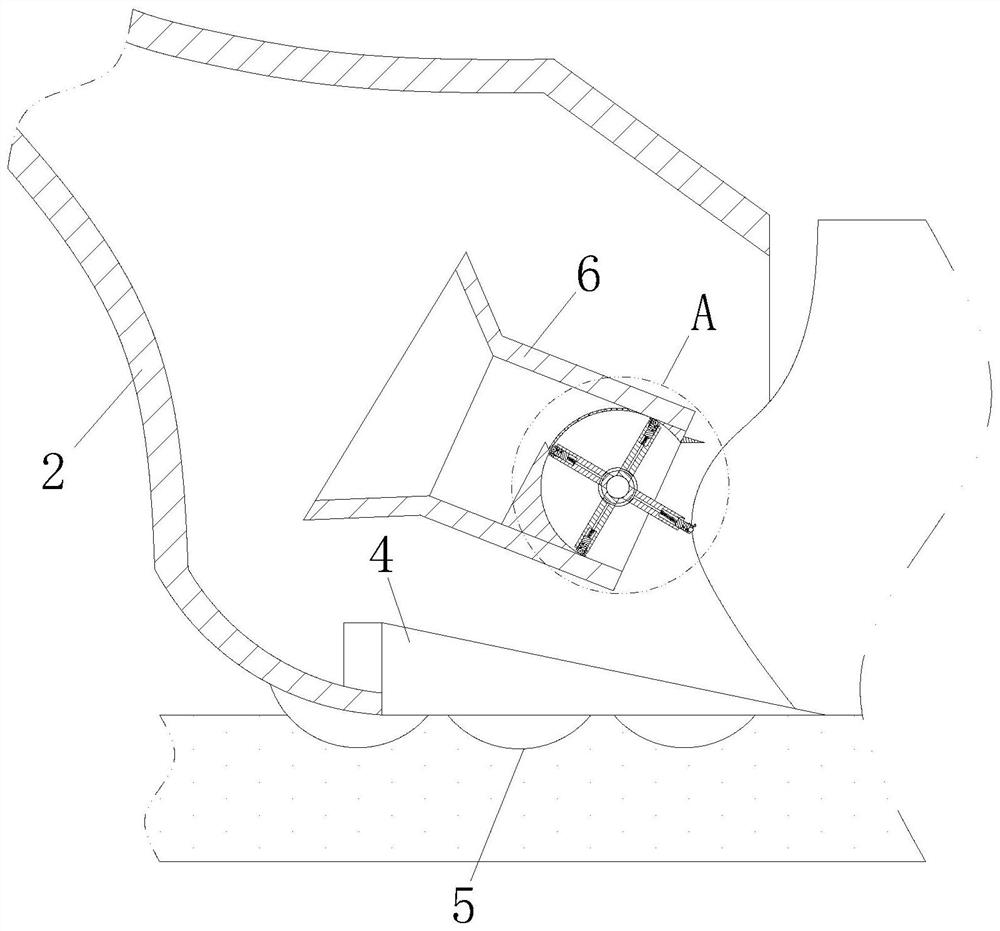

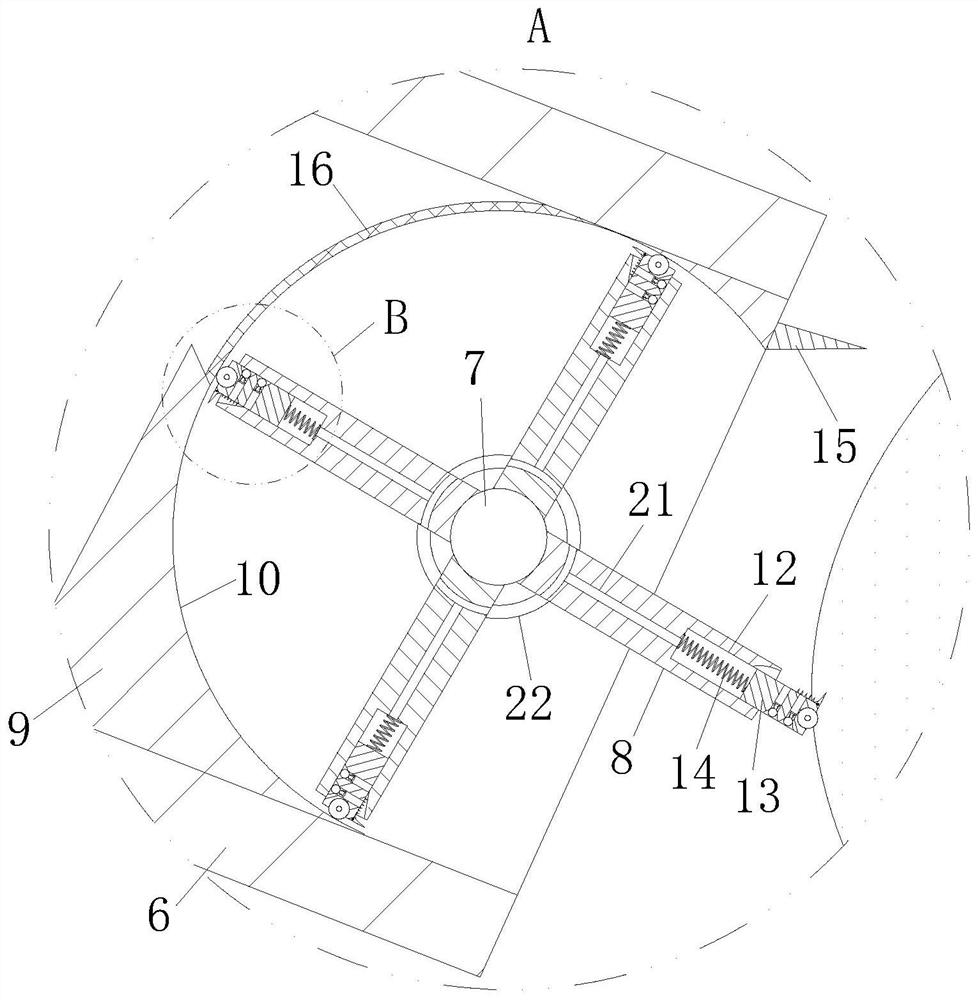

[0034] Such as Figure 1-Figure 4 As shown, a special rake head for eliminating ridges according to the present invention includes a hull 1 and a material pumping chamber 2, and a heel section 3 is provided on one side of the material pumping chamber 2; the inner bottom of the material pumping chamber 2 There are rake teeth 4 at the end, and a group of protrusions 5 are provided at the bottom of the rake teeth 4 and the pumping chamber 2. The inside of the pumping chamber 2 is provided with a partition chamber 6, and the partition chamber 6 is close to the pumping chamber 2. One side of the opening is rotatably connected with a rotating column 7, and a group of circularly uniformly distributed rotating plates 8 are connected to the side wall of the rotating column 7, and the side wall of the rotating column 7 is far away from the corresponding dividing chamber 6 of the opening side of the pumping chamber 2. The side wall is provided with a stopper 9, and one end of the stopper...

Embodiment 2

[0043] Such as Figure 5 As shown, compared with Example 1, the bottom end of the hydraulic rod 27 is provided with a transition chamber 29, the bottom end of the hydraulic rod 27 is connected with a piston 30 slidingly connected with the transition chamber 29, and the cutter 28 is installed in the transition chamber 29 At the bottom end, the two side walls of the cutter 28 are respectively provided with chute 31, the inside of the chute 31 is slidingly connected with cutting teeth 32, and an elastic member is connected between the cutting teeth 32 and the inner end of the chute 31 33, the inside of the cutter 28 is provided with an air flow groove 34 communicating with the transition chamber 29 and the chute 31, and the side wall of the cutter 28 is provided with an opening and closing groove 35 communicating with the air flow groove 34, and the opening and closing The opening and closing block 36 is slidably connected to the inside of the slot 35, and the outer end of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com