Environment-friendly anti-skinning viscosity reducer and preparation method thereof

A technology of anti-skinning agent and detackifying agent, which is applied in the field of environment-friendly anti-skinning and detackifying agent and its preparation, can solve the problem of not having antibacterial performance and anti-skinning agent performance, affecting the efficiency and quality of printing, and shortening the use of Life and other issues, to achieve the effect of improving printing performance and printing quality, good wettability and surface activity, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

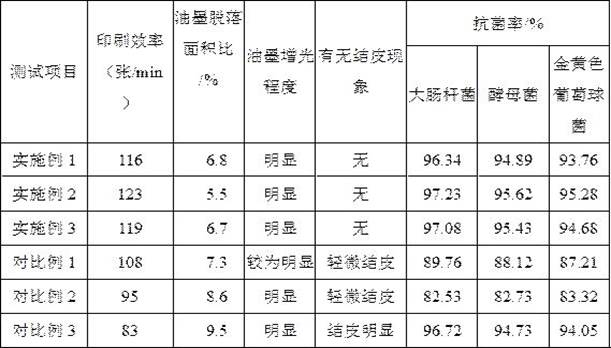

Examples

Embodiment 1

[0033] An environment-friendly anti-skinning detackifying agent, the detackifying agent is composed of the following raw materials in parts by weight: 20 parts of vaseline, 6 parts of mineral oil, 30 parts of linseed oil, 10 parts of camellia oil, 3 parts of white beeswax, 0.6 part of dehydrated sorrel Sugar alcohol monooleate, 2 parts of bergamot essential oil, 0.8 part of dodecyl gemini quaternary ammonium salt, 0.7 part of anti-skinning agent and 1.5 parts of surfactant.

[0034] Mineral oil is a narrow distillation range refined mineral oil with 55% paraffin wax content, 90% non-sulfonated content, 5 carbon number differences in the 20% distillation range range, and a pour point of less than -10°C.

[0035] The anti-skinning agent selects methyl ethyl ketone oxime.

[0036] The preparation method of bergamot essential oil is:

[0037] Take an appropriate amount of cleaned bergamot, dry and pulverize them in turn; then place the obtained bergamot micropowder with a particl...

Embodiment 2

[0049] The detackifier provided in this embodiment and its preparation method are roughly the same as in Example 1, the main difference being that the detackifier is made up of the following raw materials in parts by weight: 25 parts of vaseline, 8 parts of mineral oil, 35 parts of linseed oil, 12 1 part of camellia oil, 4 parts of white beeswax, 0.8 part of sorbitan monooleate, 3 parts of bergamot essential oil, 1.2 parts of dodecyl gemini quaternary ammonium salt, 1.0 part of anti-skinning agent and 2.0 parts of surfactant .

[0050] Mineral oil is a narrow distillation range refined mineral oil with 58% paraffin wax content, 92% non-sulfonate content, 4 carbon number differences in the 50% distillation range range, and a pour point of less than -10°C.

[0051] Butanone oxime is selected as the anti-skinning agent.

[0052] The preparation method of bergamot essential oil is:

[0053] Take an appropriate amount of cleaned bergamot, dry and pulverize them in sequence; then ...

Embodiment 3

[0063] The detackifying agent provided in this embodiment and its preparation method are roughly the same as in Example 1, the main difference being that the detackifying agent is made up of the following raw materials in parts by weight: 30 parts of vaseline, 10 parts of mineral oil, 40 parts of linseed oil, 15 parts 1 part of camellia oil, 6 parts of white beeswax, 1.0 part of sorbitan monooleate, 4 parts of bergamot essential oil, 1.5 parts of dodecyl gemini quaternary ammonium salt, 1.2 parts of anti-skinning agent and 2.5 parts of surfactant .

[0064] Mineral oil is a narrow distillation range refined mineral oil with 60% paraffin wax content, 95% non-sulfonated content, 90% distillation range with a carbon number difference of less than 3, and a pour point of less than -10°C.

[0065] The anti-skinning agent selects methyl ethyl ketone oxime.

[0066] The preparation method of bergamot essential oil is:

[0067] Take an appropriate amount of cleaned bergamot, dry and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com