Hollow positive electrode material, precursor thereof, and preparation method of precursor

A cathode material and precursor technology, which is applied in the field of hollow cathode material precursor and its preparation, can solve the problem of difficulty in large-scale and efficient production of hollow material precursor, and the inability to meet the high output power and high cycle of power batteries. The requirements of characteristics, etc., to achieve the effect of high tap density, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

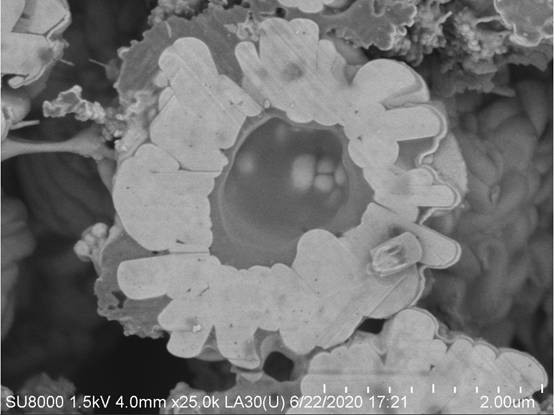

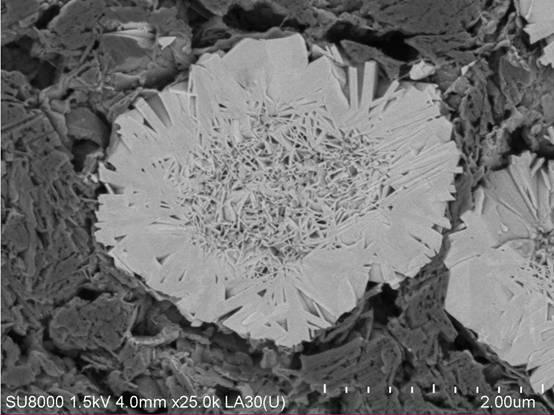

[0043] Prepare a ternary metal salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a total metal concentration of 2mol / L. The molar ratio of nickel, cobalt, and manganese is 60:20:20, and prepare a 2mol / L sodium hydroxide solution. Add pure water to the reaction kettle with a volume of 100L, control the temperature at 55°C, add ammonia water to adjust the concentration of ammonia water in the reaction kettle to 7g / L, add lye to adjust the pH to 11.80, and add 1.3L / The flow rate of min is continuously fed into the air.

[0044] In the reaction process of stage I, inject the ternary metal salt solution with the flow rate of 3.6L / h in the reactor, control reaction temperature to be 55 ℃, regulate the flow of the ammoniacal liquor and the sodium hydroxide solution injected in the reactor, make the reactor The pH inside was maintained at 11.80, the concentration of ammonia water was maintained at 7g / L, the pH was adjusted to 11.40 after 1 hour of reaction, ...

Embodiment 2

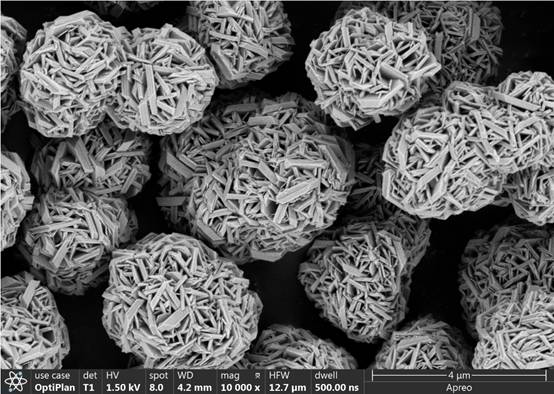

[0048] Prepare a ternary metal salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a total metal concentration of 2mol / L. The molar ratio of nickel, cobalt, and manganese is 60:20:20, and prepare a 2mol / L sodium hydroxide solution. Add pure water to the reactor with a volume of 100L, control the temperature at 55°C, add ammonia to adjust the ammonia concentration in the reactor to 7g / L, add lye to adjust the pH to 12.0, and add 0.75L / The flow rate of min is continuously fed into the air.

[0049] In the reaction process of stage I, inject ternary metal salt solution with the flow rate of 2.4L / h in the reactor, control reaction temperature to be 55 ℃, regulate the flow of the ammoniacal liquor and the sodium hydroxide solution injected in the reactor, make the reactor The pH inside was maintained at 12.0, the concentration of ammonia water was maintained at 7g / L, the pH was adjusted to 11.40 after 0.5h of reaction, the air flow rate was reduced to 0.1L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com