Bogie frame and bogie

A bogie and frame technology, applied in the field of bogies, can solve problems such as damage, stress concentration at the joint between the beam and the side beam, and easy cracking at the joint, so as to reduce stress concentration, improve the overall strength, and reduce the overall weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

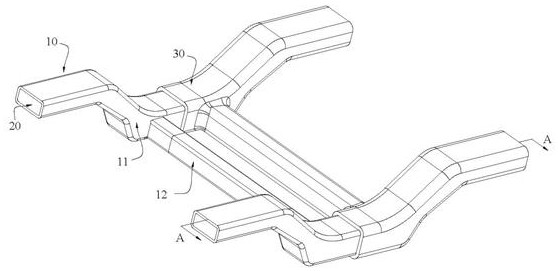

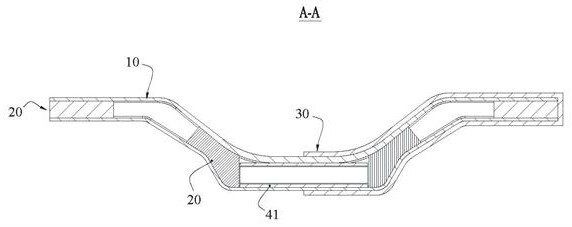

[0039] Such as Figure 1 to Figure 4 The bogie frame shown includes: a mandrel member 10, an embedded part 20 and a cladding layer 30;

[0040] The mandrel member 10 is a hollow tubular structure, including two side beam mandrels 11 arranged in parallel and a beam mandrel 12 vertically arranged between the two side beam mandrels 11; figure 1 As shown in , in this embodiment, there are two beam mandrels 12 arranged in parallel and at intervals. It should be pointed out here that the number of beams is set according to the size and strength of the vehicle body, and can also be one or more.

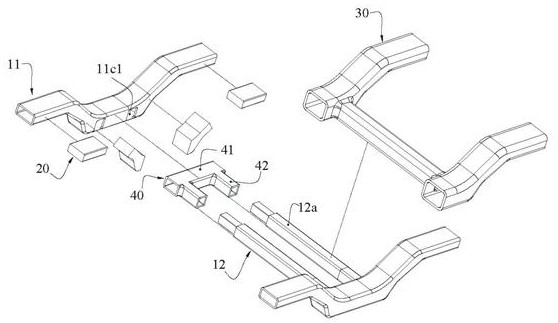

[0041] The embedded parts 20 are embedded in the side beam mandrel 11 and the beam mandrel 12 at intervals; as figure 2 with 3 As shown in , the embedded part 20 is embedded in the side beam mandrel 11 and the beam mandrel 12 when the mandrel member 10 is processed, or it can also be set only in the side beam mandrel 11 or the beam mandrel 12 according to the requirement, and the embedded...

Embodiment 2

[0048] In the first embodiment, in order to ensure the reliability of the connection between the side beam mandrel 11 and the beam mandrel 12, a connector 40 is added, an opening 11c1 is opened in the middle section 11c of the side beam mandrel 11, and a sleeve 12a is sleeved on the beam mandrel 12 , and when the crossbeam mandrel 12 is connected with the connecting joint 42, multiple drawing resin glues are required. On the one hand, this structural form increases the processing procedure and increases the production cost of the bogie frame, and the manual bonding is also unreliable. , the quality of the product is not well guaranteed;

[0049] For this reason, the product in embodiment one has been further improved, as Figure 5 In the second embodiment of this product shown in , in this embodiment, the connecting piece 40 and the sleeve 12a in the first embodiment are omitted, and the upper side beam mandrel 11 and the beam mandrel 12 of the mandrel member 10 are integrated...

Embodiment 3

[0054] In the second embodiment, the structural form of up and down butt joint is adopted, but the contact surface between the core mold member 10 of the upper half and the core mold member 10 of the lower half is relatively small. In order to further strengthen the connection structure between the two, the present invention also A third embodiment is provided, and the second embodiment is improved, such as Image 6 As shown in , the core mold component 10 is an integrated structure, the outer end of the side beam core mold 11 is a sealing structure, and the sides of the core mold component 10 are overlapped. It should be pointed out here that the integral molding structure does not mean that the core mold is made of a whole piece of prepreg, but that the core mold structure is divided into upper and lower parts during specific processing, but the connection method is as follows: Figures 7 to 9 The way of fitting the side walls in the middle, it should be pointed out here tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com