Composite film and its preparation method and application

A composite membrane and supporting membrane technology, applied in the field of water treatment, can solve the problems of ineffective filtration, affect human health, low trace elements, etc., achieve high univalent ion permeability, realize large-scale batch production, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of composite membrane provided by the invention comprises:

[0030] S1, providing an aqueous phase solution and an oil phase solution, wherein the aqueous phase solution includes polyglycerin and the first polyamine, and the oil phase solution includes polyacid halides;

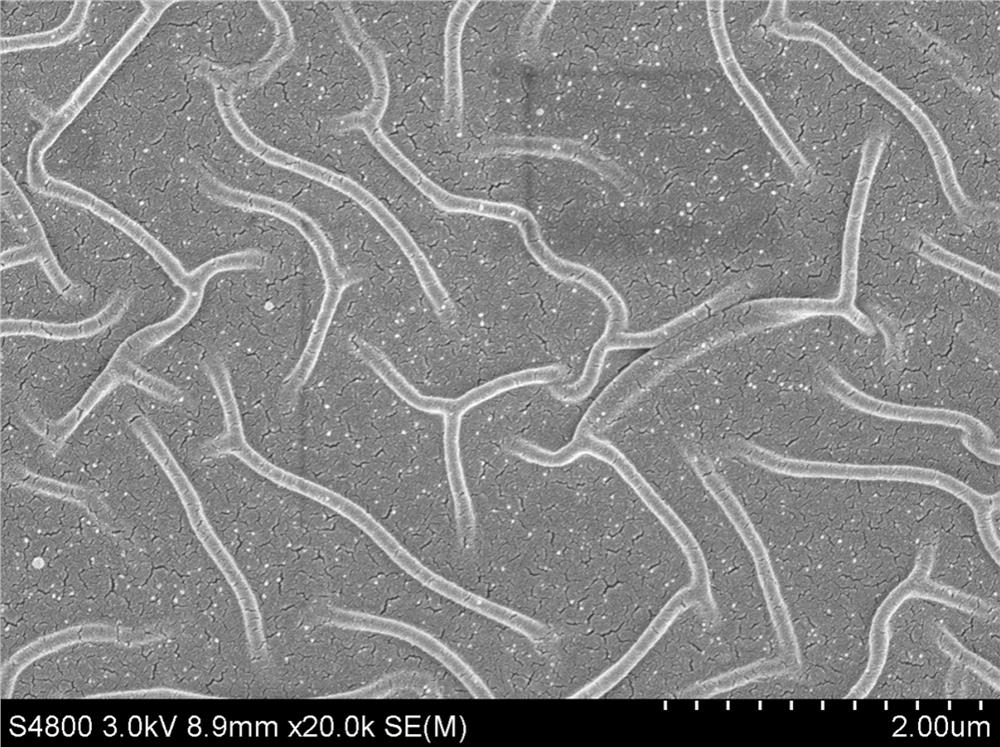

[0031] S2, providing a support membrane, placing the aqueous phase solution and the oil phase solution on the surface of the support membrane in sequence and performing a first heat treatment to form a first polyamide layer on the surface of the support membrane, wherein the The first polyamide layer also includes unreacted multi-acid halides; and

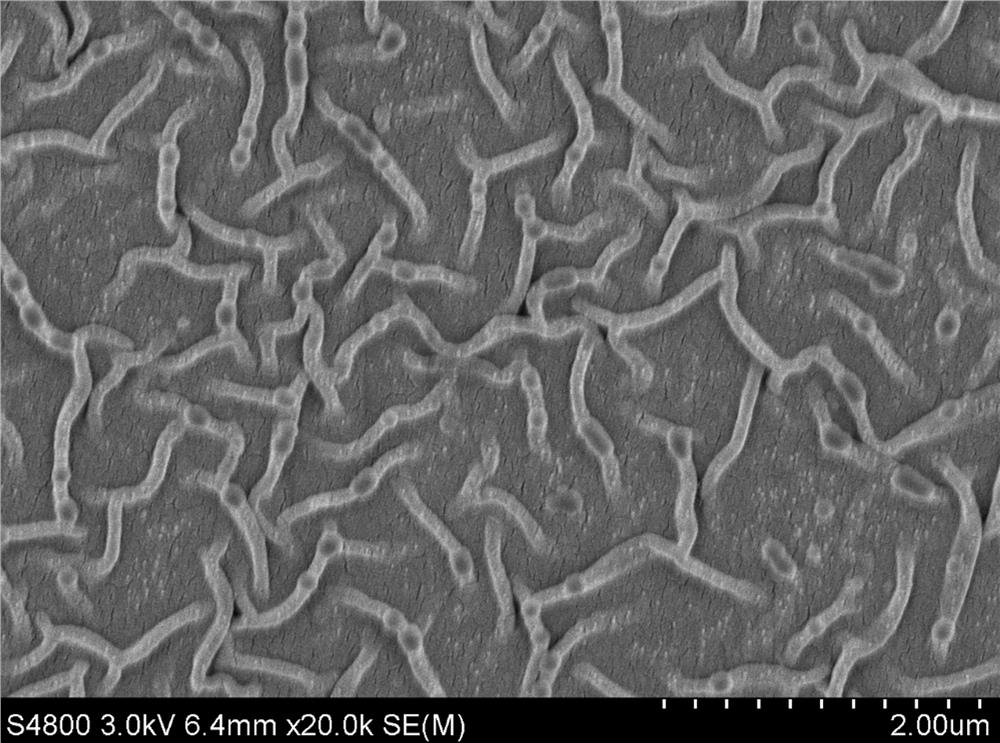

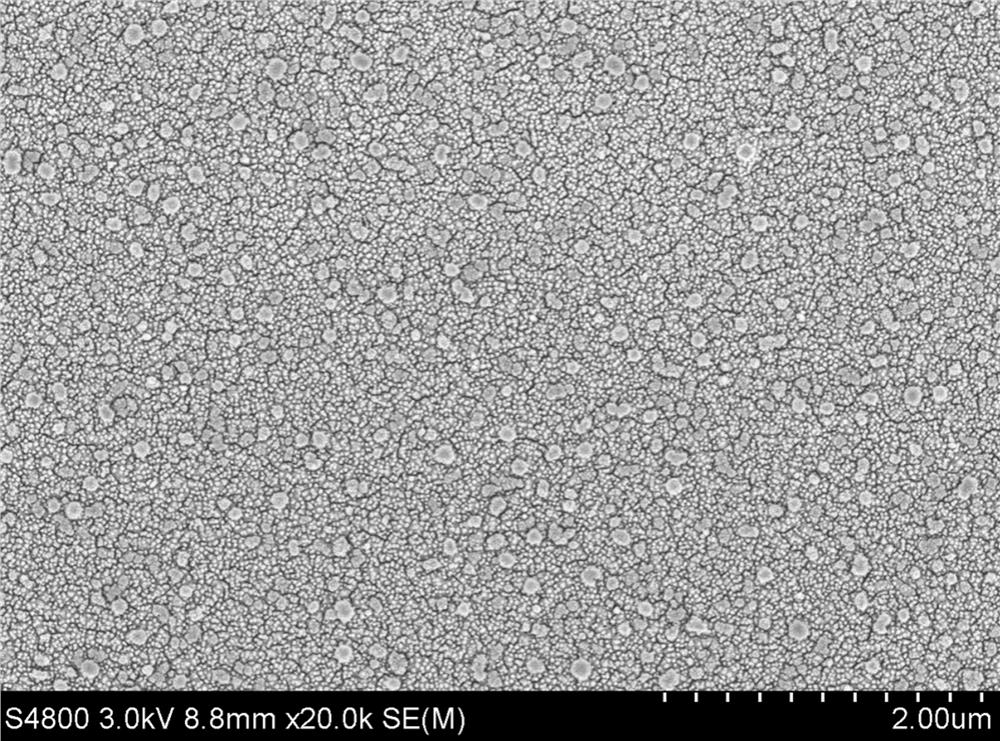

[0032] S3, provide a functional solution, the functional solution includes a second polyamine and an ionic liquid, place the functional solution on the surface of the first polyamide layer away from the support membrane and perform a second heat treatment to generate a second a polyamide layer, the second polyamide layer extends from...

Embodiment 1

[0060] Mix piperazine, triethylamine, decaglycerin and water evenly to obtain an aqueous phase solution for subsequent use, wherein the mass fraction of piperazine in the aqueous phase solution is 0.25%, the mass fraction of triethylamine is 1.5%, and decamerol The mass fraction of glycerin is 0.2%.

[0061] Mix trimesoyl chloride (TMC) and isoparaffin solvent (Isopar L) uniformly to obtain an oil phase solution for future use, wherein the mass fraction of trimesoyl chloride in the oil phase solution is 0.15%.

[0062] Mix piperazine and 1-butyl-3-methylimidazolium chloride evenly to obtain a functional solution for future use, wherein the mass fraction of piperazine in the functional solution is 0.1%.

[0063] First coat the above water phase solution on the polysulfone support membrane, pour off the excess water phase solution after standing for 60s, and dry the membrane surface with cold wind; then coat the oil phase solution on the above dried membrane surface, and let it ...

Embodiment 2

[0068] Mix piperazine, triethylamine, pentaglycerol and water evenly to obtain an aqueous phase solution for subsequent use, wherein the mass fraction of piperazine in the aqueous phase solution is 0.35%, the mass fraction of triethylamine is 1.5%, and the pentameric The mass fraction of glycerin is 0.35%.

[0069] Mix trimesoyl chloride (TMC) and isoparaffin solvent (Isopar L) uniformly to obtain an oil phase solution for later use, wherein the mass fraction of trimesoyl chloride in the oil phase solution is 0.2%.

[0070] Mix piperazine and 1-butyl-3-methylimidazolium tetrafluoroborate chloride evenly to obtain a functional solution for future use, wherein the mass fraction of piperazine in the functional solution is 0.15%.

[0071] First coat the above water phase solution on the polysulfone support membrane, pour off the excess water phase solution after standing for 60s, and dry the membrane surface with cold wind; then coat the oil phase solution on the above dried membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com