Automatic strand pulling machine for beam field

An automatic beam field technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as large deviations between tensile stress and elongation, construction that does not meet design specifications, and practical applications. , to achieve the effect of improving cutting efficiency, meeting the requirements of manual and automatic integration, and avoiding adverse wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

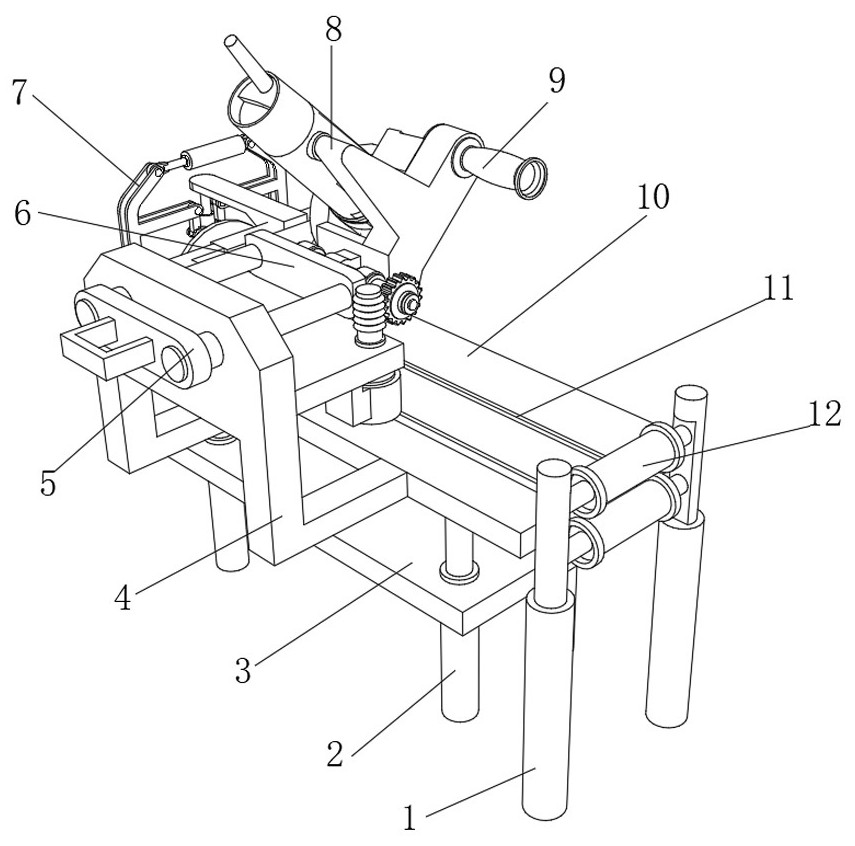

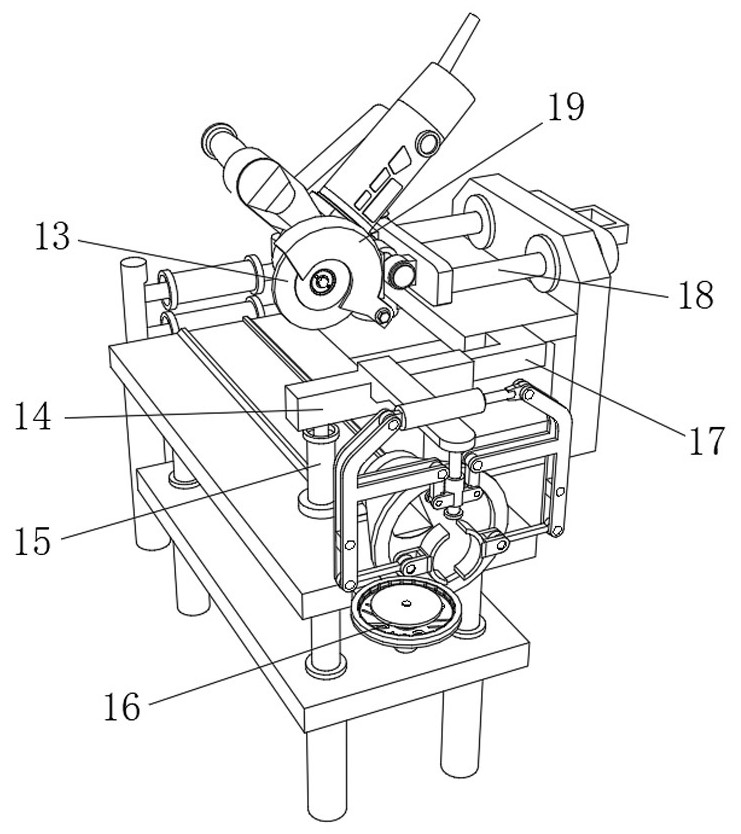

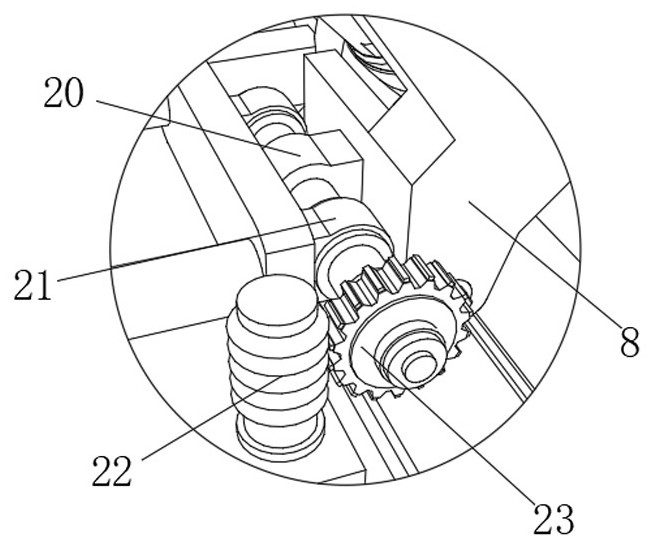

[0037] Beam field automatic beam threading machine, such as Figure 1-4 As shown, it includes a bottom plate 3, a workbench 10, two fixed columns 1 and a prestressed steel beam frame. Four pillars 2 run through the bottom of the bottom plate 3 and the workbench 10, and the tops of the two fixed columns 1 are on the opposite side of the outer wall. The push wheels 12 are respectively fixed by two rotating rods, the mounting frame 4 is fixed on one side of the workbench 10 by bolts, a support plate is provided on one side of the mounting frame 4, and a push-pull rotation mechanism is provided on the top of the mounting frame 4, and the push-pull One side of the rotating mechanism is fixed with a connecting plate 6 by bolts, and one side of the connecting plate 6 is rotatably connected with a fixed frame 8, and the outer wall of one side of the fixed frame 8 is fixed with a grinding wheel cutting machine 13 by bolts, and one side of the grinding wheel cutting machine 13 is passed ...

Embodiment 2

[0045] Beam field automatic beam threading machine, such as Figure 5 As shown, in order to avoid shifting when the steel bundle is pushed; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of the side of the workbench 10 near the bottom of the binding mechanism 7 has a mounting groove, and the mounting groove The inner wall of the traction bucket 32 is fixed with a traction bucket 32 by bolts, and the outer wall of one side of the traction bucket 32 is fixed with a mounting ring 34 through threads, and a hole 33 is opened on one side of the mounting ring 34, and a flexible pad is welded on the outer wall of the bottom side of the mounting ring 34 31; when the steel beam passes through the traction bucket 32, the tunnel 33 in the installation ring 34 can effectively limit and guide the steel beam, and the flexible pad 34 also avoids a large area of wear during the steel beam pushing process, which promotes Integrity of the te...

Embodiment 3

[0047] Beam field automatic beam threading machine, such as Figure 6-7 As shown, in order to facilitate the installation of the steel beam, the prestressed steel beam frame includes three first brackets 35, twenty-four second brackets 36, twenty-four third brackets 37, and eight fourth brackets 38 , sixteen stop rods 39 and sixteen sliding seats 40, and three first brackets 35 are respectively fixed on one side of the workbench 10 by bolts, and every six second brackets 36 are respectively fixed on three sides by steel strands. One side of the first bracket 35, every three third brackets 37 are respectively fixed on the top side of every two second brackets 36 by steel strands, and every two fourth brackets 38 are respectively fixed on three sides by steel strands. At the bottom of the first bracket 36, each sliding seat 40 is welded to the top circumference side of each second bracket 36 respectively, and each stop rod 39 is slidably connected in each sliding seat 40; throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com