Connection device and connection method of T-shaped steel keel of inclined curtain wall

A technology of connecting device and T-shaped steel, applied in the direction of walls, buildings, building components, etc., can solve the problems of difficult screwing and installation of locking screws, affecting the installation stability of locking screws, reducing the construction quality of glass curtain walls, etc. Connection efficiency and construction quality, improve processing accuracy and installation accuracy, and avoid the effect of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

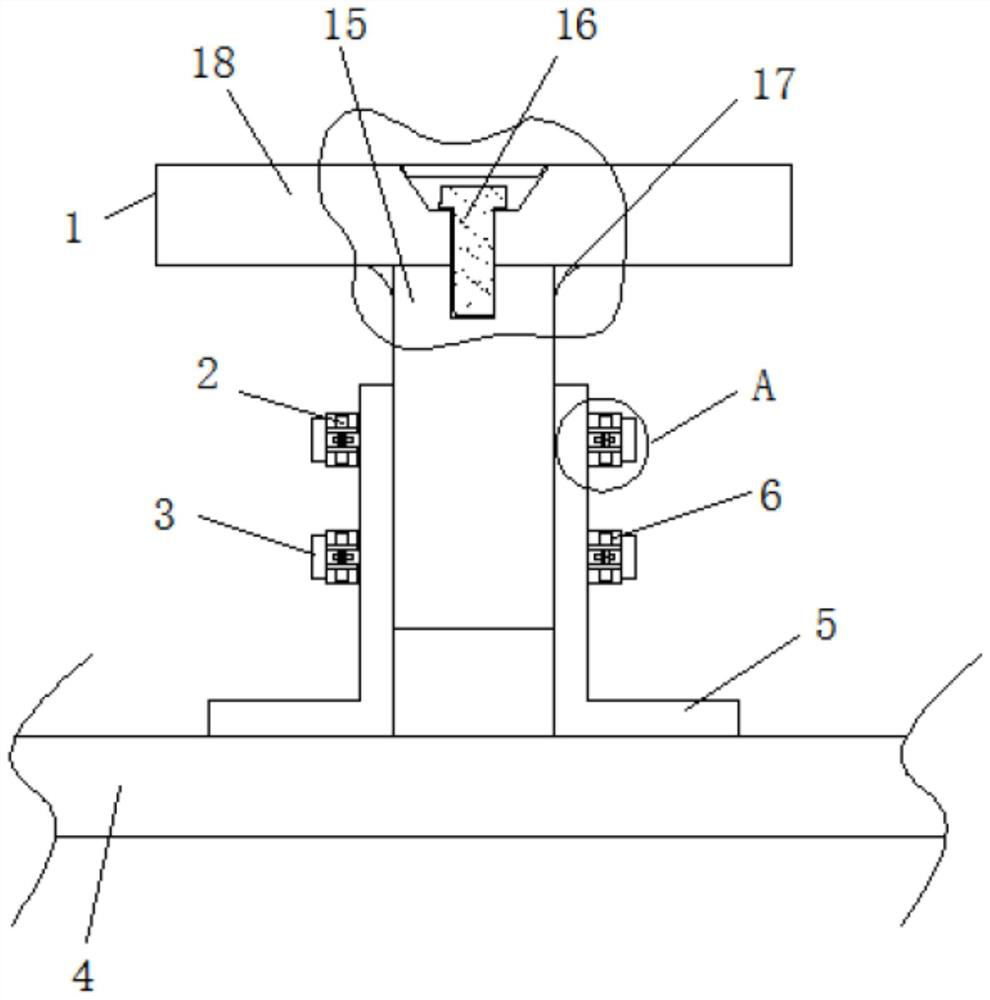

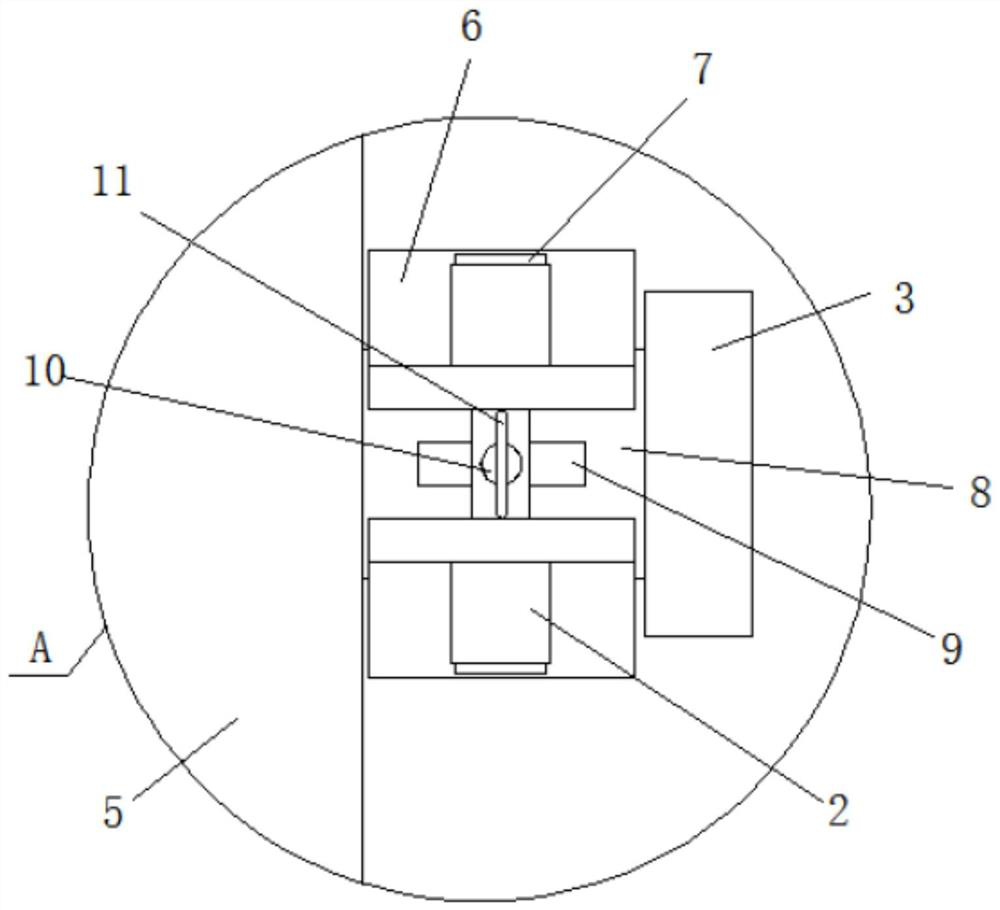

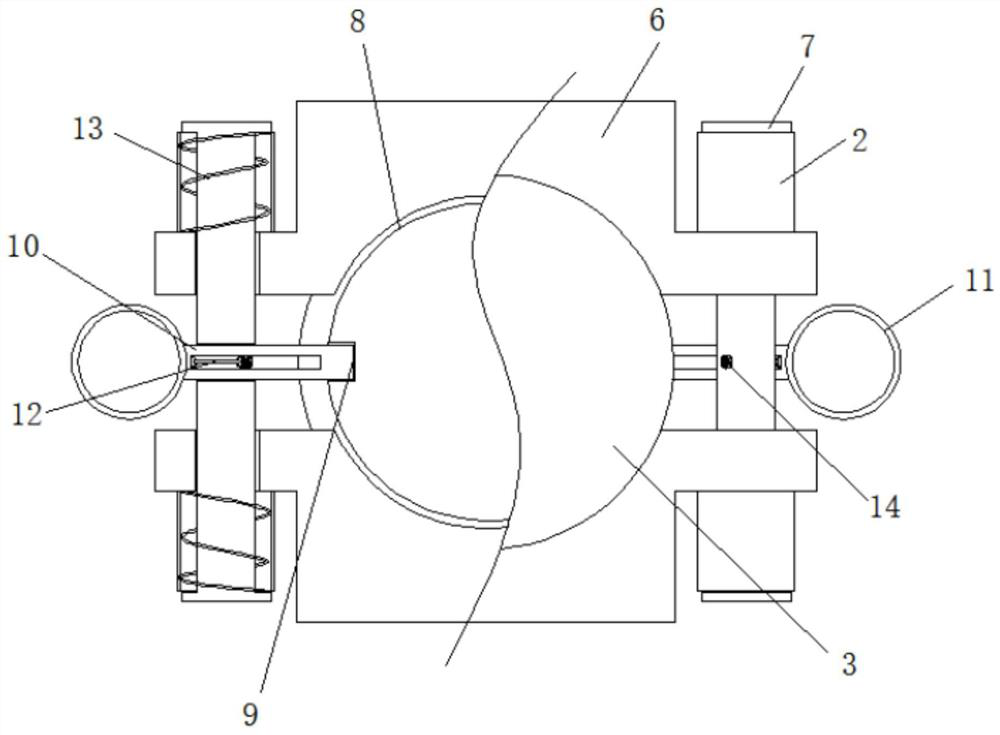

[0036] Please see attached figure 1 and attached figure 2 , a connecting device for a T-shaped steel keel of an inclined curtain wall, comprising a glass curtain wall 4 connected at one end of a connecting plate 5, and a connecting device main body for connecting one end of the T-shaped steel 1 and the other end of the L-shaped connecting plate 5; the connecting device main body includes The fixing column 3, the connecting block 6, the connecting column 7 and the sliding locking assembly; the connecting surface of the T-shaped steel 1 and the connecting plate 5 is formed with a first through hole matching the fixing column 3, so that the fixing column 3 can pass through the first through hole. A through hole vertically penetrates the T-shaped steel 1 and the connecting plate 5; the two ends of the fixing column 3 are formed with a clamping slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com