A kind of high-concentration tetrapropyl ammonium hydroxide production process and the high-concentration tetrapropyl ammonium hydroxide prepared therefrom

A technology of tetrapropylammonium hydroxide and tetrapropylammonium bromide, which is applied in the field of quaternary ammonium alkali production, can solve problems such as low concentration temperature, affecting product quality, and affecting production efficiency of high-concentration tetrapropylammonium hydroxide products. , to achieve the effect of increasing the concentration temperature, shortening the concentration time, and shortening the electrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

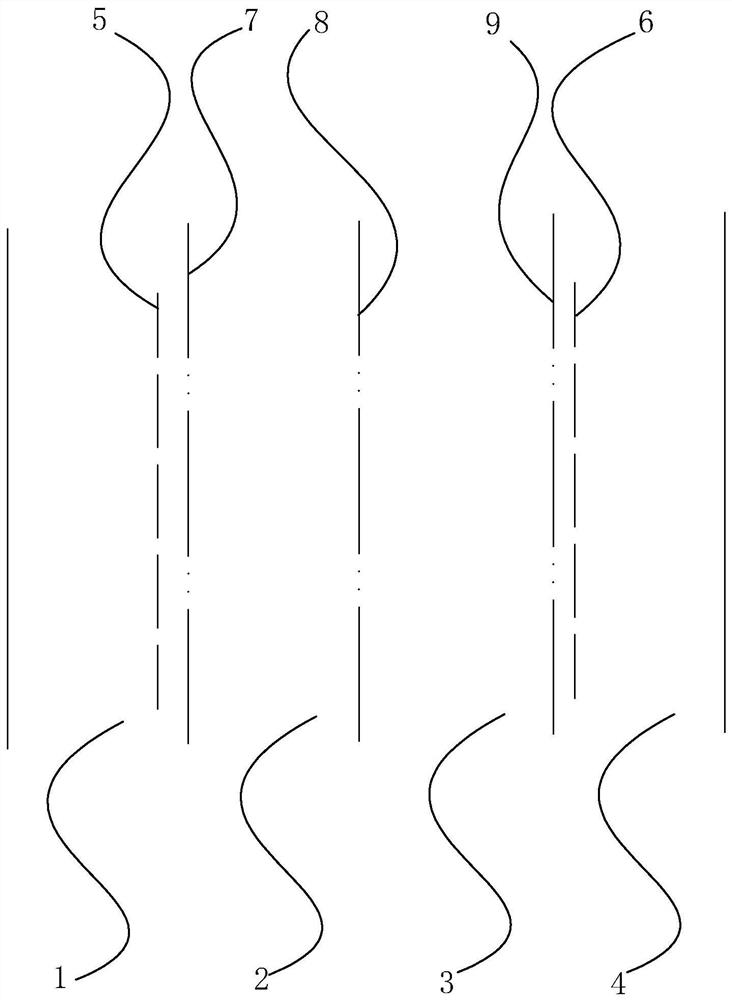

[0040] Embodiment 1: high-concentration tetrapropyl ammonium hydroxide production process, use electrolyzer to carry out electrolysis, as figure 1 As shown, the electrolytic cell includes an anode chamber 1, a by-product chamber 2, a raw material chamber 3 and a cathode chamber 4 which are successively adjacent at the same height; an anode plate 5 is installed in the anode chamber 1, and a cathode plate 6 is installed in the cathode chamber 4 , the anode plate 5 is connected to the cathode plate 6 through a power supply; the anode chamber 1 communicates with the by-product chamber 2 through the first cationic membrane 7, the by-product chamber 2 communicates with the raw material chamber 3 through the anion membrane 8, and the raw material chamber 3 and The cathode chambers 4 are communicated through the second cationic membrane 9; the production process includes the following steps:

[0041] S1 electrolysis: take tetrapropylammonium bromide, add water to prepare tetrapropylam...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that step S2 of Example 2 was concentrated in a water bath at 80° C. for 125 minutes without cooling down the concentration process, and the others were consistent with Example 1.

Embodiment 3-6

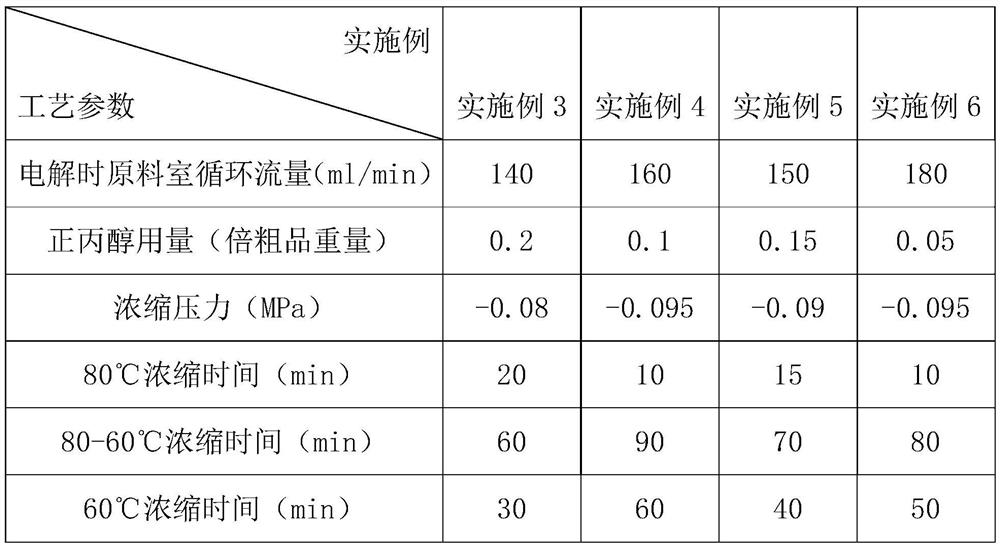

[0046] The difference between embodiment 3-6 and embodiment 1 is that the process parameters of each step of embodiment 3-6 are different, the circulation flow rate of material in the anode chamber, by-product chamber and cathode chamber is 120ml / min, and others are all kept with embodiment 1 Consistent, each step process parameter of embodiment 3-6 is shown in Table 1.

[0047] Each step technological parameter of table 1 embodiment 3-6

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com