Recovery treatment device applied to concentrated water of chemical water production system

A technology for recovery and treatment of concentrated water, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve waste of water resources, impurities prone to salt, and uneven filtration of solid substances And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

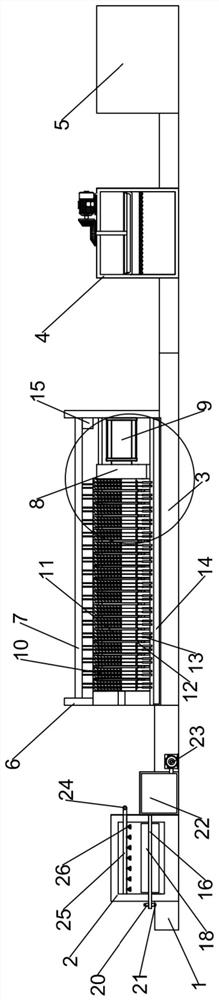

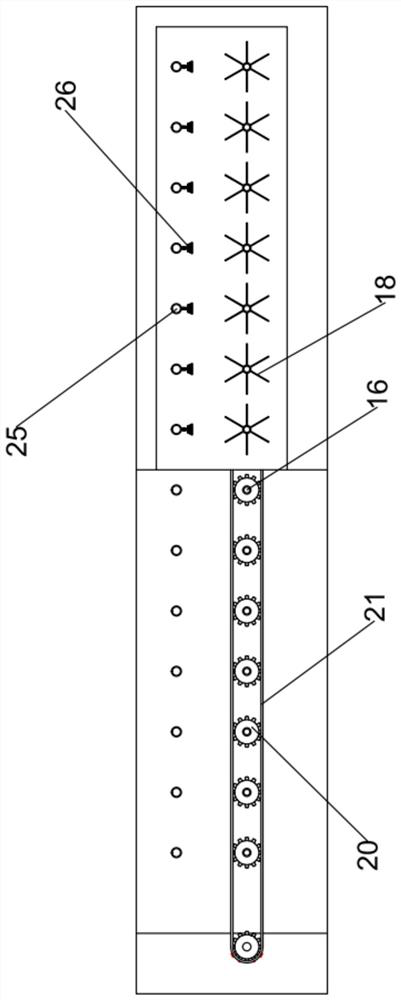

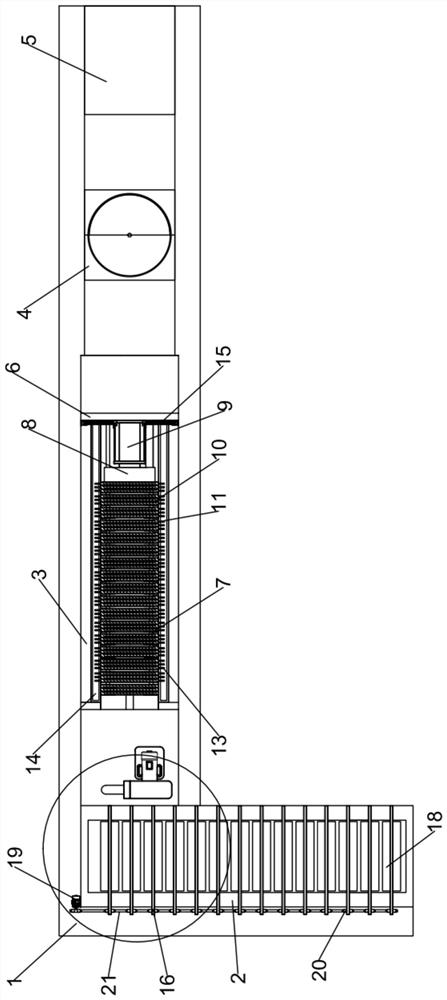

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5As shown, a recovery and treatment device applied to concentrated water in a chemical water system includes: a recovery support 1, a mixing tank 2, a filter table 3, an evaporation tank 4 and a cooling tank 5, and the recovery support 1 is installed on the On the mixing and stirring box 2, the filtering platform 3, the evaporation box 4 and the cooling box 5, a mixing and stirring structure is installed in the mixing and stirring box 2, a shunt structure is installed in the described filtering platform 3, and a Evaporation structure, cooling structure is installed in the cooling box 5; the split flow structure includes: extrusion bracket 6, two pairs of support limit shafts 7 with the same structure, extrusion plate 8, extrusion hydraulic cylinder 9, several Extruded concave plates 10 with the same structure, several filter plates 11 with the same structure, sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com