Sulfur hexafluoride gas cylinder safe loading and unloading auxiliary device and working method thereof

A technology of sulfur hexafluoride and auxiliary device, applied in the direction of lifting device, etc., can solve the problems of easy slippage, bursting of high-pressure gas cylinder, low loading and unloading efficiency, etc., and achieve the effect of enhancing friction, enhancing magnetic flux, and enhancing magnetic force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

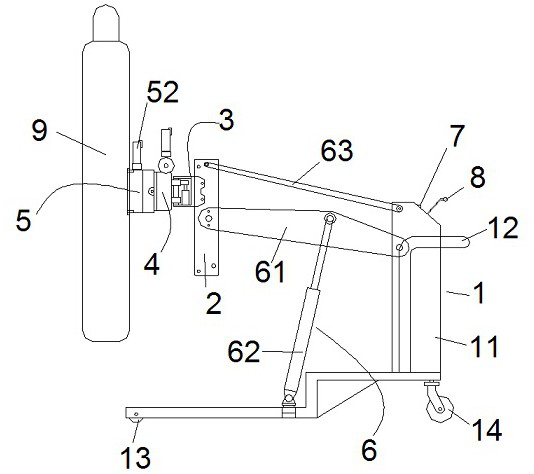

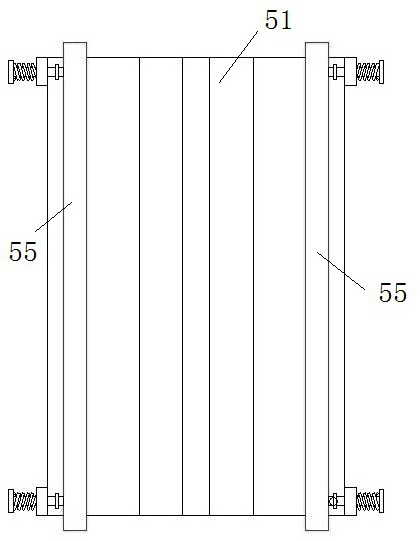

[0025] Example: such as Figure 1~9 As shown, in this embodiment, an auxiliary device for safe loading and unloading of sulfur hexafluoride gas cylinders is provided, including a mobile trolley 1, the left side of the mobile trolley is sequentially provided with a liftable magnetic base 2 from right to left, and a landing The buffer device 3, the servo-driven rotary device 4, and the V-groove permanent magnet chuck assembly 5 for fixing the sulfur hexafluoride cylinder 9, the servo-driven rotary device is used to drive the rotation of the V-groove permanent magnet chuck assembly to realize hexafluoride Horizontal or vertical placement of sulfur gas cylinders.

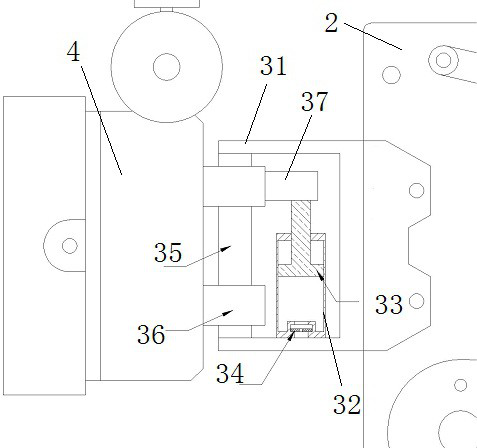

[0026] In this embodiment, the landing buffer device 3 includes a buffer body 31, an air buffer cylinder 32 is arranged in the middle of the buffer body, a piston 33 is arranged inside the air buffer cylinder, and the air buffer cylinder The bottom surface of the body is provided with a gravity perforated valve plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com