Trailer collision brake

A technology for trailers and trailer bars, applied in the field of trailer crash brakes, can solve problems such as hidden safety hazards, easily damaged crash brake balls, insufficient safety, etc., and achieve the effects of improving safety, meeting safety requirements, and having a long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

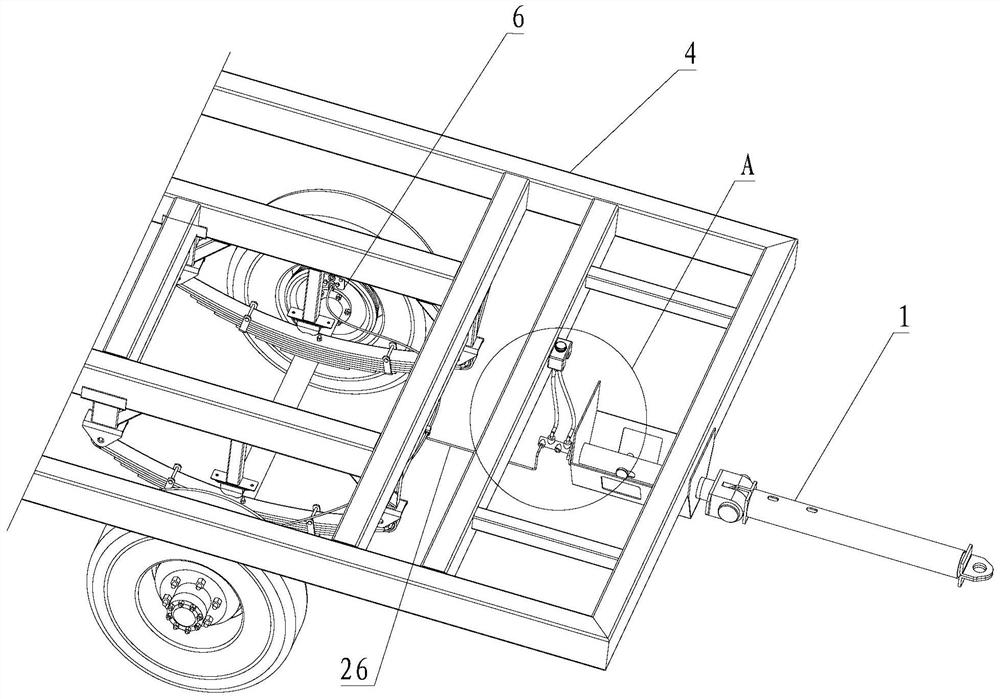

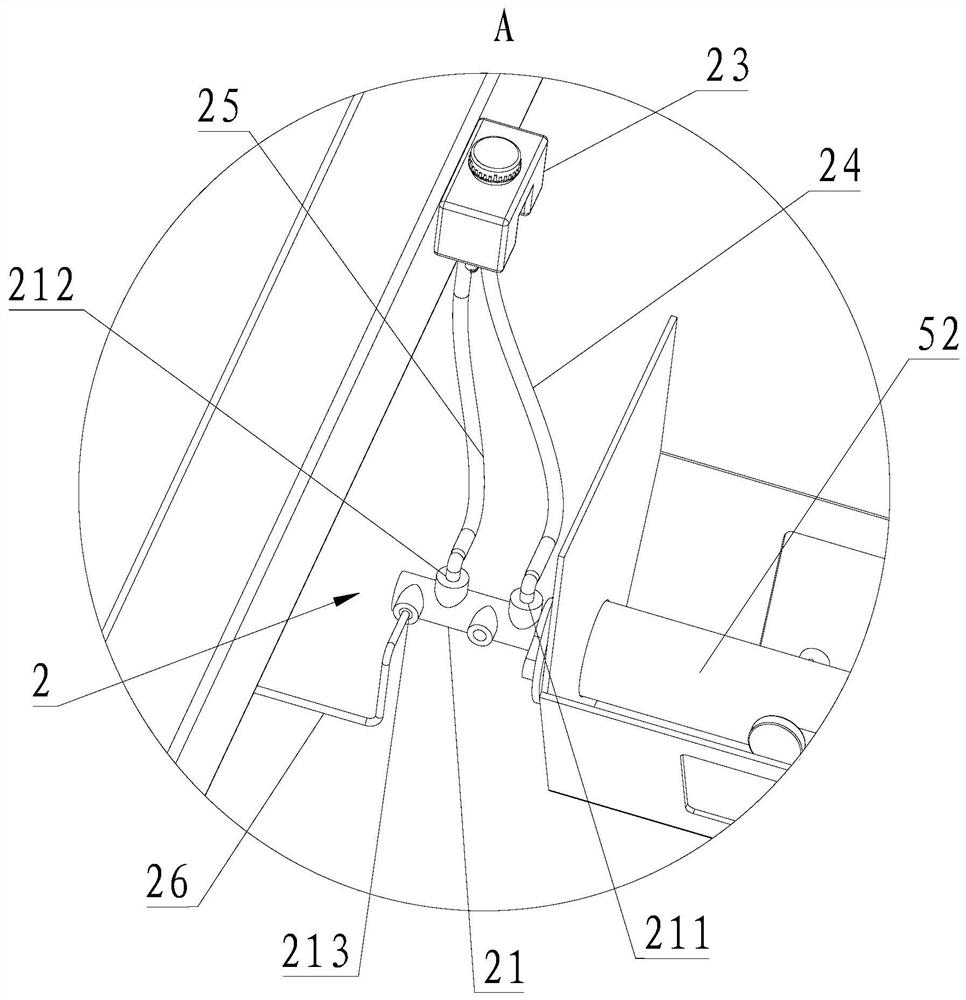

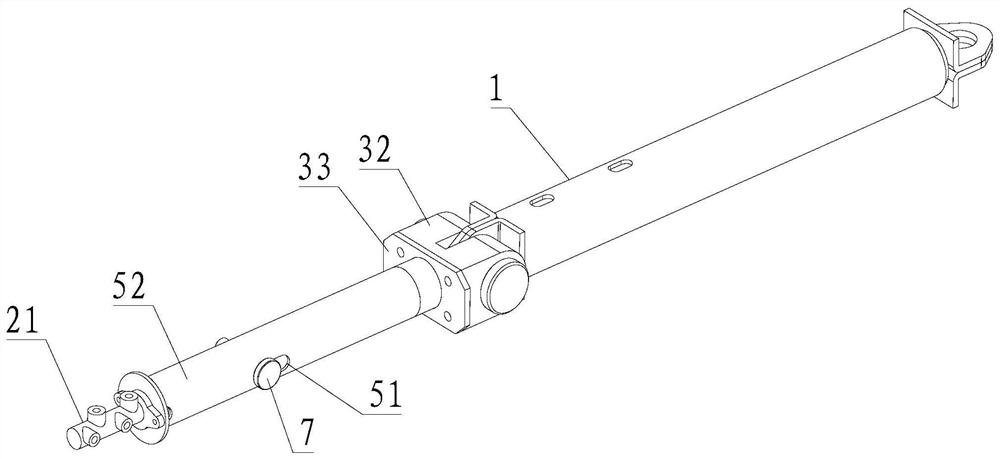

[0070] refer to Figure 1-Figure 8 , a trailer bump brake, including a trailer rod assembly 1 for connecting with a tractor, including a brake pump assembly 2, a striker rod assembly 3 and a brake rod assembly 5 installed on a trailer frame 4; There is a braking cavity 54 in the brake lever assembly 5, and one end of the braking cavity 54 has an opening 541; the braking end of the lance assembly 3 matches the opening 541; the lance assembly 3 is set through the opening 541 and inserted in the brake cavity 54; the lance assembly 3 is connected with the brake lever assembly 5 through the stopper 7, so that the lance assembly 3 can always be in the brake cavity 54 along the brake cavity 54 axial movement; the trailer rod assembly 1 is installed on the end of the striker rod assembly 3 away from the brake pump assembly 2; the output end of the brake pump assembly 2 is used for the front axle brake assembly 6 of the trailer Connected; the input end of the brake pump assembly 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com